High-Quality M12 Steel Washers for Secure Fastening

Sep . 07, 2024 02:22 Back to list

High-Quality M12 Steel Washers for Secure Fastening

Understanding M12 Steel Washers Specifications and Applications

M12 steel washers are essential components commonly used in various industrial and construction applications. Their designation, M12, refers to the metric size of the washer, which has a nominal inner diameter of approximately 12 millimeters. These washers are typically made from steel, offering durability and strength, which makes them suitable for heavy-duty applications. In this article, we will delve into the specifications, types, and applications of M12 steel washers.

Specifications of M12 Steel Washers

M12 steel washers are available in several specifications that define their dimensions and physical properties. The outer diameter of an M12 washer commonly ranges from 24 mm to 30 mm, providing an ample surface area to distribute the load of the bolt or nut. The thickness of M12 washers can also vary, typically from 1.5 mm to 3 mm, depending on the specific requirements of the application.

Steel washers are often categorically classified into different grades based on the strength and tensile properties of the steel used. The most commonly used grades for M12 washers include Grade 8.8 and Grade 10.9. These grades are characterized by their high tensile strength, making them ideal for heavy load-bearing applications where reliability is critical.

Types of M12 Steel Washers

There are several types of M12 washers, each designed for specific uses

1. Flat washers These are the most common type of washers used with M12 bolts. They provide a smooth surface, helping to distribute the load evenly and preventing damage to the surfaces being fastened.

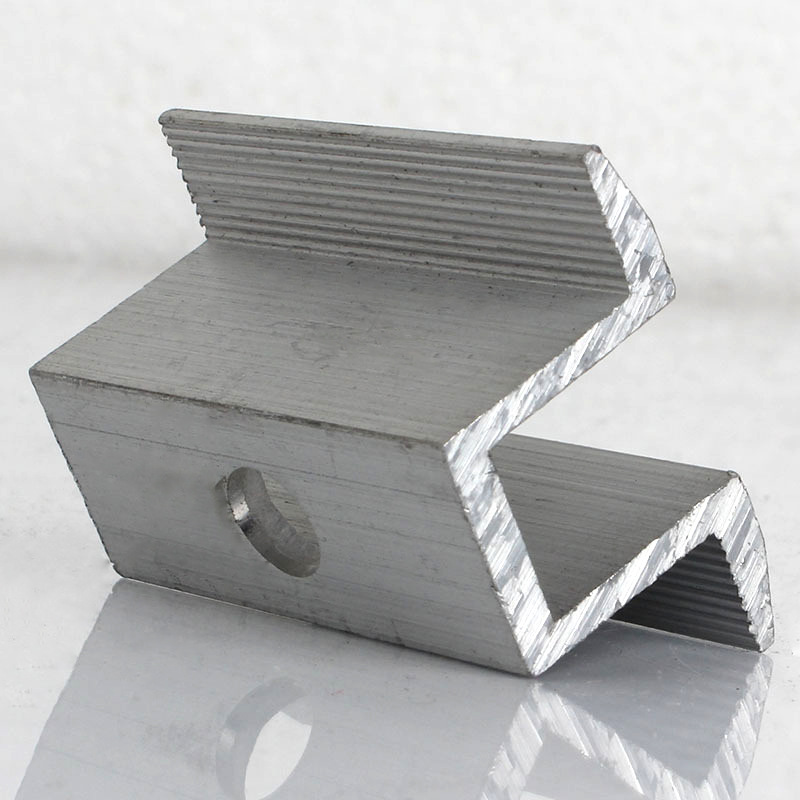

m12 steel washers

2. Spring washers These washers, often known as lock washers, provide a spring effect that helps maintain tension by preventing the bolt from loosening due to vibrations or dynamic loads.

3. Fender washers Featuring a larger outer diameter, fender washers are used when a broader load distribution is required. They are especially useful in applications where the surface material is relatively soft, as they minimize the risk of embedding.

4. Belleville washers These conical washers offer a unique spring action and are mainly used in applications requiring elasticity in fastening systems.

Applications of M12 Steel Washers

M12 steel washers are versatile and find applications across various industries, including automotive, construction, and manufacturing. Their primary role is to enhance the fastening system by providing a stable surface for secure connections. In the automotive industry, they are commonly used in assembling parts, ensuring that connections withstand vibrations and dynamic forces.

In construction, M12 washers are vital in securing bolts and nuts used for structural beams, ensuring safety and stability in buildings. Additionally, their use in machinery and equipment assembly underlines their critical role in maintaining operational efficiency.

Conclusion

In summary, M12 steel washers are indispensable components in numerous applications due to their strength, durability, and versatility. Understanding their specifications, types, and applications is crucial for selecting the right washer for any project. Investing in high-quality M12 steel washers ensures reliable and secure connections in any assembly, contributing to the overall integrity of the construction or machinery involved.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025