M10 Flange Nut with 20mm Width and 1.0mm Pitch Specifications Available Now

Dec . 21, 2024 09:31 Back to list

M10 Flange Nut with 20mm Width and 1.0mm Pitch Specifications Available Now

Understanding M10 20 x 1.0 Flange Nut Key Features and Applications

M10 20 x 1.0 flange nuts are essential components in various mechanical and structural applications. With a unique design that combines the functionalities of a nut and a washer, these fasteners provide enhanced performance and durability. In this article, we will explore the intricate details of M10 20 x 1.0 flange nuts, including their specifications, advantages, and typical applications.

Specifications

The designation of M10 20 x 1.0 provides crucial information about the dimensions and threading of the flange nut. The M10 refers to the nominal diameter of the nut, which is 10 millimeters. The 20 denotes the thread pitch, meaning there are 20 threads per inch, and 1.0 indicates the height of the nut. Additionally, the flange, which is integrated into the nut, has a larger surface area that acts like a washer.

The flange nut is typically constructed from strong materials like steel, stainless steel, or other alloys. These materials ensure that the nut can withstand considerable tension and shear forces, making it suitable for a range of environments, including those exposed to corrosive elements.

Design Features

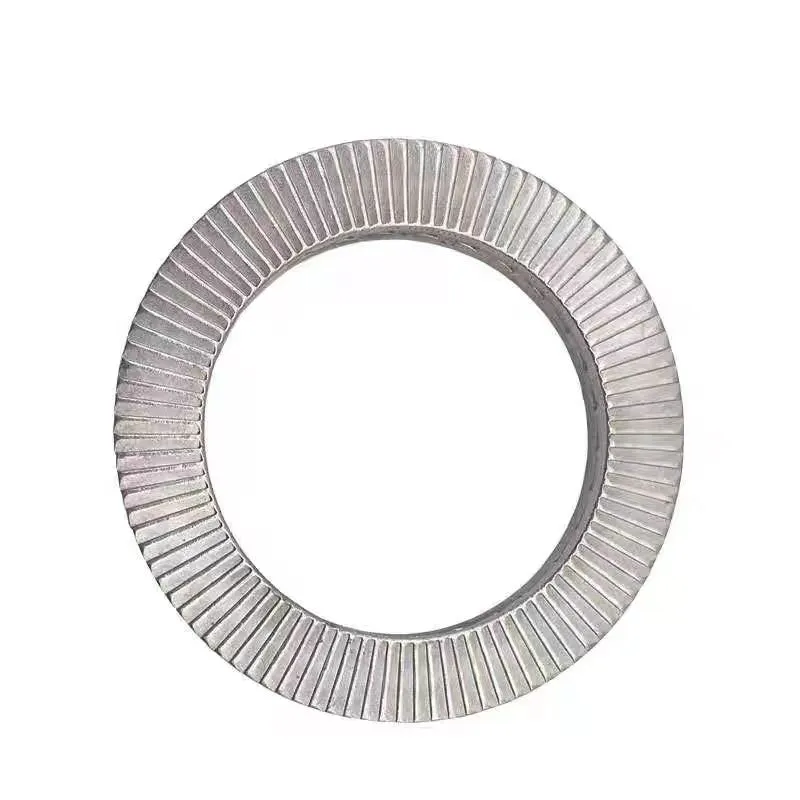

One of the standout features of M10 20 x 1.0 flange nuts is their wider bearing surface due to the flange. This design minimizes the risk of the nut loosening over time, as it distributes the load evenly across a larger area. The flange also provides an additional level of friction, which is particularly beneficial in dynamic environments where vibration is present.

Moreover, these nuts are often designed with a serrated flange, adding further grip and preventing slippage. This is crucial in applications where safety and stability are paramount.

Advantages

m10 x 1.0 flange nut

The M10 20 x 1.0 flange nut offers several advantages over traditional nuts. First, the integration of the flange reduces the need for separate washers, simplifying assembly and reducing the number of components required. This can lead to significant cost savings in large-scale projects.

Second, the flange nut's ability to maintain its grip even under fluctuating load conditions makes it ideal for machinery and automotive applications. It minimizes the risk of joints becoming loose, which can lead to mechanical failure and potentially hazardous situations.

Finally, the variety of materials in which these nuts are available means that they can be suited for both indoor and outdoor applications. Stainless steel variants, for example, are perfect for marine and coastal environments due to their excellent resistance to rust and corrosion.

Applications

M10 20 x 1.0 flange nuts are widely used across numerous industries. In the automotive sector, they are employed in engine assemblies and chassis construction, where durability and security are vital. In construction, these nuts secure structural components together, ensuring that buildings and bridges can withstand significant loads.

They also find utility in furniture assembly and manufacturing, as the flange provides stability, keeping the materials securely in place. Additionally, in the realm of electronics, these nuts serve as critical fasteners for various devices, ensuring that components are tightly secured without the risk of loosening.

Conclusion

In summary, M10 20 x 1.0 flange nuts are versatile and reliable fasteners that enhance the integrity of mechanical assemblies. Their unique design, combined with robust materials, makes them a preferred choice for engineers and manufacturers alike. By understanding the features and applications of these essential components, professionals can make informed decisions that enhance the safety and reliability of their projects. Whether in automotive, construction, or electronics, the M10 20 x 1.0 flange nut stands out as a superior fastening solution.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025