long self tapping screws for metal

Oct . 05, 2024 11:32 Back to list

long self tapping screws for metal

Understanding Long Self-Tapping Screws for Metal Applications

In the realm of construction and manufacturing, the selection of fasteners is critical to the integrity and durability of structures and products. Among these, long self-tapping screws specifically designed for metal applications stand out due to their versatility and ease of use. In this article, we will delve into the characteristics, advantages, and applications of long self-tapping screws for metal.

What are Long Self-Tapping Screws?

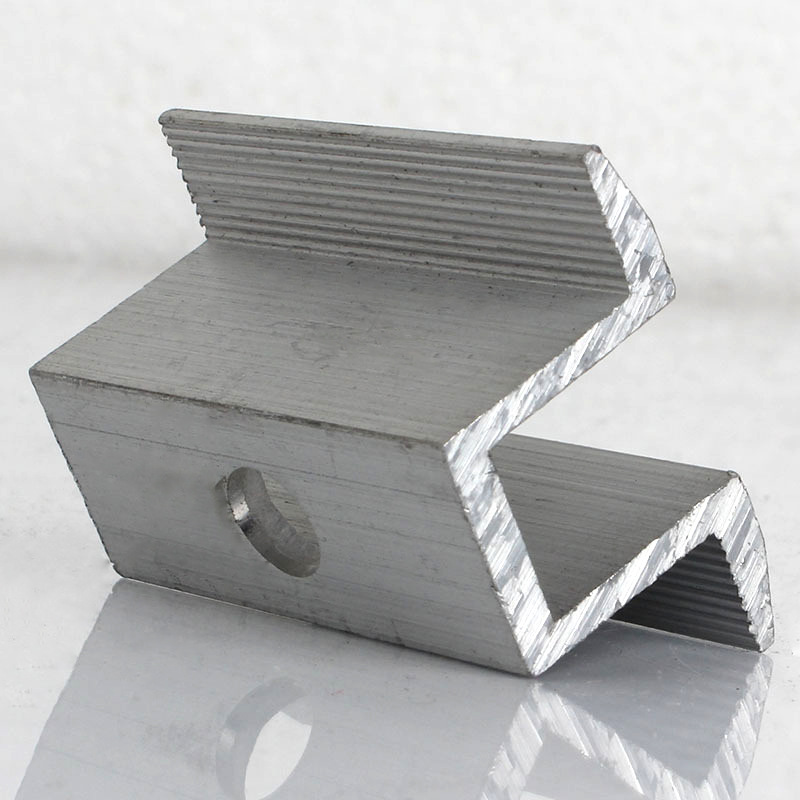

Self-tapping screws are a type of fastener that can create their own holes as they are driven into materials. Unlike conventional screws that require pre-drilled pilot holes, self-tapping screws are engineered with sharp threads and a pointed tip that enables them to cut into materials, particularly metals, with minimal effort. Long self-tapping screws, usually ranging from 1.5 inches to 3 inches or even longer, are designed for applications requiring deeper penetration into thicker metal substrates.

Characteristics

1. Material Composition Long self-tapping screws are typically made from carbon steel, stainless steel, or other alloys. The choice of material affects the screw's strength, corrosion resistance, and overall performance.

2. Thread Design The threads on self-tapping screws vary in design and pitch. The more coarse threads are advantageous for softer metals, while finer threads are better suited for harder materials. The thread design also helps in securing the screw tightly within the material, reducing the risk of loosening due to vibration.

3. Point Design The tip of a long self-tapping screw may have different designs, such as sharp points for metal or blunt points for use in plastic or wood. For metal applications, a sharp point with a slight taper allows easy penetration and reduces the likelihood of the screw bending or breaking during installation.

4. Coating and Finish To enhance corrosion resistance and longevity, many long self-tapping screws are zinc-plated or coated with other protective materials. This is particularly important in applications exposed to moisture or harsh environmental conditions.

Advantages of Using Long Self-Tapping Screws for Metal

1. Ease of Installation One of the primary benefits of using self-tapping screws is the elimination of the need for pre-drilled holes. This reduces labor time and costs, enabling faster assembly processes in manufacturing and construction tasks.

long self tapping screws for metal

2. Secure Connections Long self-tapping screws provide a robust connection that can withstand considerable loads and stresses. Their design ensures they create a strong bond with the metal, offering reliability in structural applications.

3. Versatility These screws can be used in a diverse range of applications, including HVAC systems, automotive parts, metal roofing, and fabrication industries. Their adaptability makes them a go-to choice for numerous projects.

4. Reduced Risk of Damage Because self-tapping screws form their own holes, there is less risk of damaging the surrounding material compared to traditional fastening methods that involve driving screws into pre-drilled holes.

Applications of Long Self-Tapping Screws

Long self-tapping screws are commonly employed in various sectors

- Construction and Metal Fabrication Used for joining steel beams, metal sheets, and other structural elements, they ensure strong and secure framework installations. - Automotive Industry These screws are utilized for attaching components like panels, fenders, and engine parts, where strength and reliability are paramount.

- HVAC Systems In heating and cooling systems, long self-tapping screws are essential for securing ductwork and other metal components together.

- Home Improvement Projects For DIY enthusiasts, long self-tapping screws can be invaluable when constructing metal sheds, fences, or any metal-to-metal connections in home projects.

Conclusion

Long self-tapping screws for metal applications offer a reliable and efficient fastening solution in various industries. Their unique design allows for easy installation, strong connections, and versatility across multiple applications. As the demand for durable and efficient construction methods continues to grow, these fasteners will remain integral in ensuring structural integrity and longevity in metal works. Understanding their features and benefits can aid in selecting the right fasteners for any project, ultimately leading to better outcomes and enhanced safety.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025