M16 Lock Washer Specifications and Applications for Reliable Fastening Solutions

Dec . 04, 2024 16:01 Back to list

M16 Lock Washer Specifications and Applications for Reliable Fastening Solutions

Understanding M16 Lock Washers Essential Components for Reliability

Lock washers, specifically the M16 size, play a crucial role in various mechanical assemblies, ensuring that bolts and nuts remain securely fastened under diverse operating conditions. Whether in automotive applications, industrial machinery, or construction projects, these components are vital for reliability and safety.

What is a Lock Washer?

A lock washer is a mechanical device that is used alongside a nut to prevent loosening due to vibration or dynamic loads. They are designed to provide additional friction and resistance that counters the rotational forces that can cause fasteners to become loose over time. There are several types of lock washers, including split washers, tooth washers, and external/internal tooth lock washers, each catering to different applications and offering various advantages.

The Significance of M16 Lock Washers

The designation M16 refers to the metric size of the fastener, which has a nominal diameter of 16 mm. M16 lock washers are typically used with M16 bolts and nuts. Their proper selection and installation are crucial in applications where mechanical integrity and performance are paramount. M16 lock washers are particularly valuable in situations where equipment operates at high speeds or is subjected to significant vibrations, making them a standard choice in many engineering and manufacturing sectors.

Types of M16 Lock Washers

1. Split Lock Washers These are the most common type and feature a split that gives them a spring-like action. When compressed, they exert pressure against both the fastener and the surface, creating resistance to loosening.

2. Tooth Lock Washers These washers have sharp teeth that grip the surface of the material and the fastener. They can be designed as external or internal tooth types, offering superior locking capabilities in high-vibration applications.

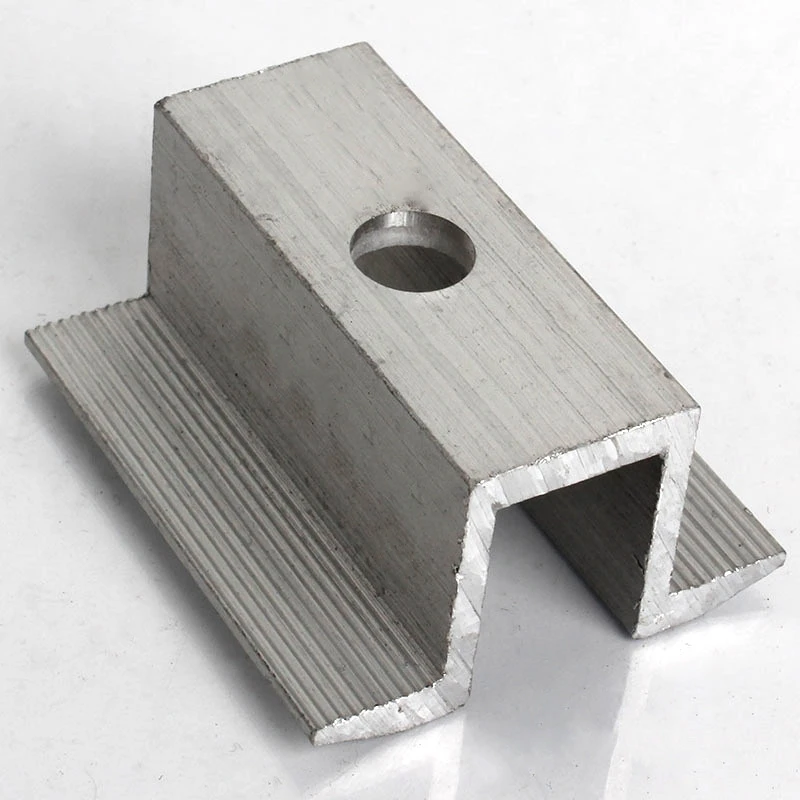

lock washer m16

3. Wave Lock Washers This type of washer has a wavy form, which allows it to absorb shock and further prevent loosening. Wave washers are particularly useful in applications where flexibility and compliance are needed along with locking capabilities.

Benefits of Using M16 Lock Washers

- Prevention of Fastener Loosening As mentioned, one of the primary benefits is their ability to maintain torque, preventing nuts and bolts from loosening over time. This is especially important in safety-critical applications such as automotive assembly and structural connections.

- Vibration Resistance M16 lock washers are designed to withstand vibrations from machinery or environmental factors, making them ideal for dynamic applications.

- Cost-Effectiveness Considering their role in extending the lifespan of fasteners, lock washers can be a cost-effective solution to reduce maintenance costs and repair time.

- Ease of Installation M16 lock washers are easy to install and require no special tools or equipment, which aids in quicker assembly processes.

Conclusion

In conclusion, M16 lock washers are indispensable components in various engineering and industrial applications. Their ability to lock fasteners in place enhances mechanical integrity, contributing to the safety and longevity of equipment. Understanding the specific types of M16 lock washers and their applications can help engineers and technicians make informed decisions, ultimately leading to better, more reliable designs. As technology evolves, so too will the designs and materials of lock washers, but their principal role in mechanical assemblies will undoubtedly remain indispensable.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025