large self tapping metal screws

Oct . 10, 2024 20:33 Back to list

large self tapping metal screws

Large Self-Tapping Metal Screws An Essential Tool for Construction and Repair

In the realm of construction and repair, one often encounters a variety of fasteners. Among these, large self-tapping metal screws have carved out a significant niche. These screws play a crucial role in ensuring that materials stay securely fastened, especially in projects involving metal, wood, and other composite materials. In this article, we will delve into the unique properties, applications, and advantages of these essential tools.

Understanding Self-Tapping Screws

Self-tapping screws are designed to create their own hole as they are driven into a material. Unlike conventional screws, which require a pre-drilled hole, self-tapping screws have a specially designed tip that cuts into the material, facilitating a tight grip without additional preparatory work. This characteristic significantly accelerates the assembly process and makes them particularly appealing for both professional and DIY use.

The Design of Large Self-Tapping Metal Screws

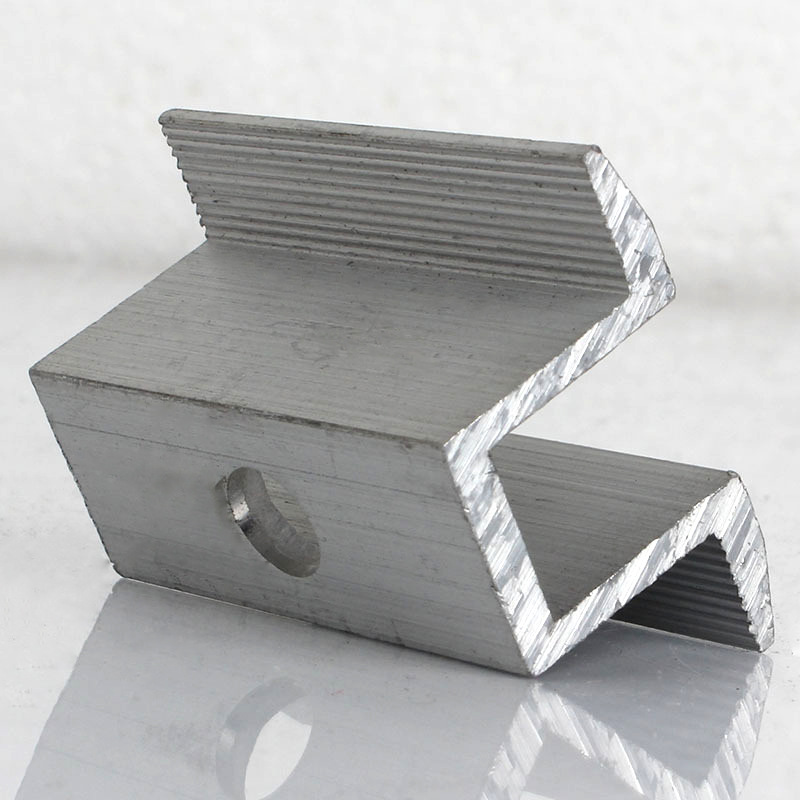

Large self-tapping metal screws typically range from size 10 to 24 in diameter, with lengths varying from half an inch to several inches. Made from high-strength materials such as hardened steel or stainless steel, these screws are engineered to withstand high levels of stress and environmental factors, including moisture and temperature changes. They often feature coarse threads, which enhance their holding power in metal materials.

The head of these screws can vary in design – common types include pan, flat, and hex heads. Each design serves different purposes hex heads allow for better torque application while flat heads lend themselves to a flush finish. Additionally, the presence of a coating, such as zinc or black oxide, helps to resist corrosion and increases the screw's longevity.

Applications of Large Self-Tapping Metal Screws

large self tapping metal screws

The versatility of large self-tapping metal screws makes them suitable for a wide array of applications. In construction projects, they are often employed to attach metal sheeting, structural components, and framing together. They are equally valuable in automotive and manufacturing industries, where they facilitate assembly processes and repair work.

In residential contexts, these screws can be used for tasks ranging from securing metal fixtures to building outdoor furniture. Their properties also make them ideal for HVAC installations, where metal ductwork must be securely joined. The ease of use of self-tapping screws can help streamline these projects, minimizing labor time and reducing the potential for errors.

Advantages of Using Large Self-Tapping Metal Screws

One of the primary advantages of large self-tapping metal screws is their ability to save time. As they eliminate the need for pre-drilling, projects can progress more quickly. This efficiency can be particularly beneficial in large-scale applications, where the volume of screws needed can be substantial.

Durability is another significant benefit. Given their robust design and material composition, large self-tapping metal screws can provide exceptional holding power, even in demanding environments. This resilience minimizes the risk of loosening, ensuring that structures remain secure over time.

Furthermore, their versatility allows for use in various materials beyond just metal, including wood and plastic, provided the appropriate type is selected. This adaptability enhances their value as a staple tool for builders, contractors, and hobbyists alike.

Conclusion

In summary, large self-tapping metal screws are remarkable fasteners that combine efficiency, durability, and versatility. Whether in construction, manufacturing, or home improvement projects, these screws simplify the fastening process and ensure the integrity of the work. As the construction industry continues to evolve, the reliance on innovative solutions like large self-tapping metal screws is likely to increase, affirming their place as indispensable tools for any toolbox. Investing in quality self-tapping screws can make a significant difference in project outcomes, contributing to both precision and longevity in various applications.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025