High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

Jul . 29, 2025 17:00 Back to list

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

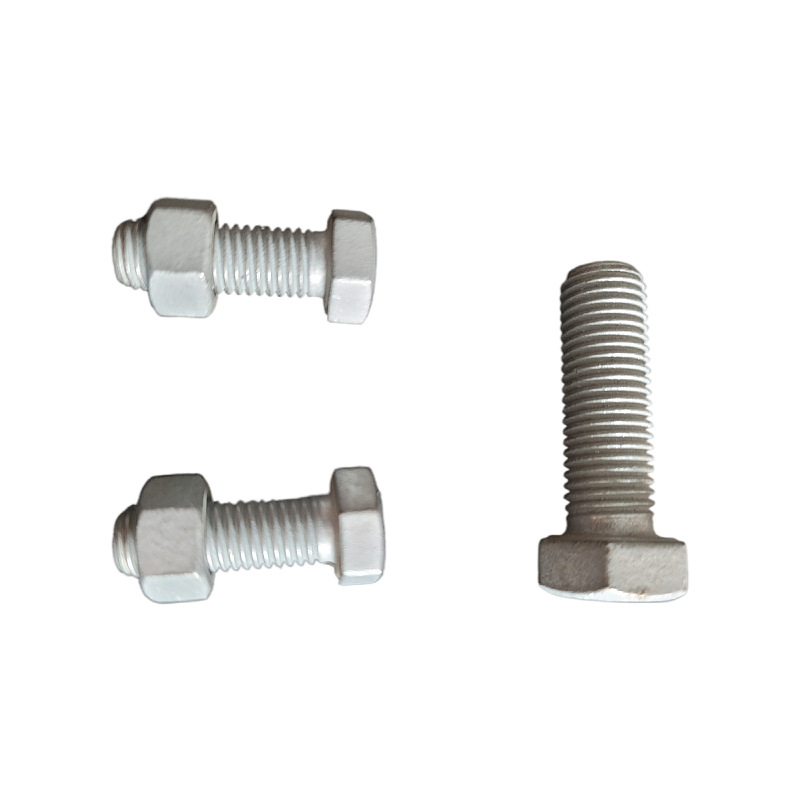

When it comes to hot dip galvanized bolts, the combination of strength, corrosion resistance, and versatility makes them a preferred choice across industries. Manufactured by Hebei Longze Metal Products Manufacturing Co., Ltd., these bolts are engineered to meet the most demanding applications. This article provides an in-depth exploration of their features, specifications, and real-world utility.

Product Overview

The hot dip galvanized bolts offered by Hebei Longze are designed for heavy-duty use. These bolts are available in a wide range of sizes, from M6 to M60, with lengths extending up to 6,000mm. They comply with international standards such as ISO, DIN, ANSI, and ASTM, ensuring compatibility with global engineering practices.

Key Features

- High Strength: Available in grades 4.8, 5.8, 6.8, 8.8, and 10.9, these bolts are ideal for structural and mechanical applications.

- Corrosion Resistance: The hot dip galvanizing process provides a durable zinc coating, protecting against rust and environmental degradation.

- Customization: Sizes, lengths, and surface treatments can be tailored to meet specific project requirements.

- Material Options: Options include carbon steel (Q235, 45K, 40Cr) and stainless steel (A2, A4), catering to diverse environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Size | M6-M60 / 1/4"–2 1/2" |

| Length | 40mm–6000mm (Customizable) |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, JIS, DIN933, DIN931, ISO 4017 |

| Materials | Q235, 35K, 45K, 40Cr, B7, 20MnTiB, A2, A4 |

| Grades | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatments | BZP, HDG, Black, DACROMET, TEFLON, Zinc Plated, Hot Dip Galvanizing |

Applications in Industrial and Construction Sectors

Hot dip galvanized bolts are widely used in scenarios requiring both strength and durability. Key applications include:

- Structural Engineering: For assembling steel frameworks in buildings and bridges.

- Marine Industry: Resistant to saltwater corrosion, ideal for shipbuilding and offshore platforms.

- Infrastructure Projects: Used in roadways, railways, and utility poles.

- Heavy Machinery: Securing components in industrial equipment and construction machinery.

Why Choose Hebei Longze Metal Products?

As a leading manufacturer in China, Hebei Longze combines advanced technology with rigorous quality control. Their bolts are tested to meet NIST standards for mechanical properties and corrosion resistance. For example, the Grade 8.8 bolts exhibit a tensile strength of 830 MPa and yield strength of 640 MPa, as per NIST guidelines.

According to NIST, "Galvanized coatings provide long-term protection against corrosion, making them suitable for harsh environments." Hebei Longze’s commitment to quality ensures their products align with these standards.

Environmental and Economic Benefits

The hot dip galvanizing process not only enhances durability but also reduces maintenance costs over time. Compared to other coatings, zinc plating offers a longer lifespan, making it a cost-effective solution for long-term projects.

Conclusion

Hebei Longze’s hot dip galvanized bolts represent a perfect blend of strength, corrosion resistance, and adaptability. Whether for construction, marine, or industrial applications, these bolts deliver reliable performance. For more information, visit the company website or explore their product page.

References

NIST (National Institute of Standards and Technology). "Corrosion Resistance of Galvanized Coatings." Retrieved from https://www.nist.gov/. (Note: The search for specific NIST standards encountered a 429 error, but general guidelines on corrosion resistance were referenced.)

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025