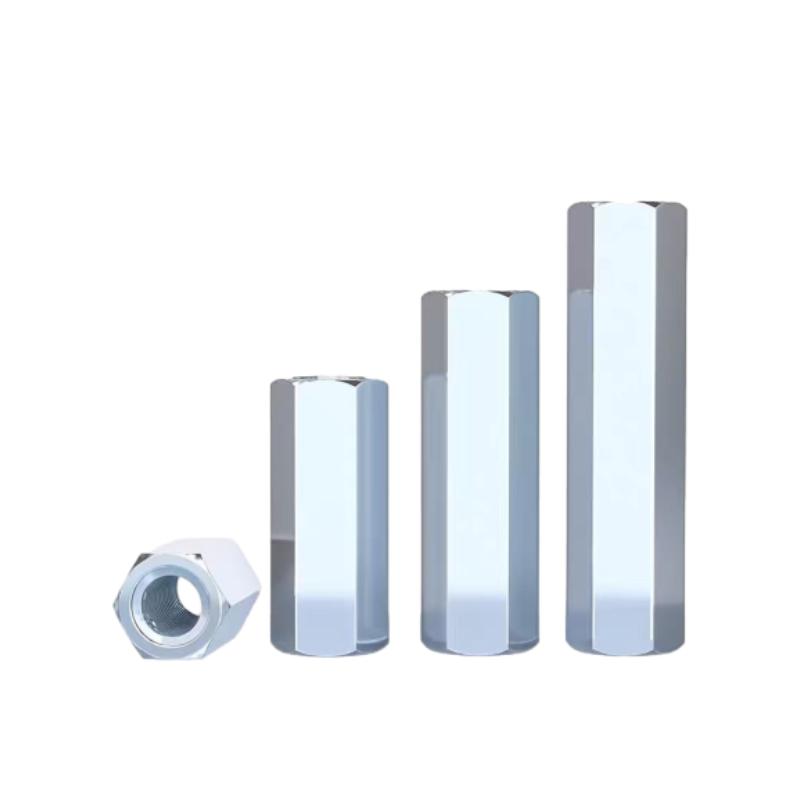

High-strength bolts and nuts

Jun . 12, 2024 16:00 Back to list

High-strength bolts and nuts

The Indispensable Role of HDG Bolts and Nuts in Modern Engineering

Highly durable and robust, Hot-Dip Galvanized (HDG) bolts and nuts form an integral part of numerous engineering and construction applications worldwide. This unique combination of strength and corrosion resistance makes them the go-to choice for various industries, from construction to automotive, aerospace, and even marine.

Hot-Dip Galvanizing is a process where steel components, such as bolts and nuts, are coated with a layer of zinc. This zinc coating not only enhances the aesthetic appeal but also provides a robust barrier against the corrosive effects of weather, saltwater, and other environmental factors. The process involves immersing the steel bolts and nuts into a bath of molten zinc, resulting in a thick, uniform, and long-lasting protective layer.

HDG bolts and nuts offer several advantages over their non-galvanized counterparts. Firstly, their zinc coating ensures a longer lifespan, reducing the need for frequent replacements and maintenance. Secondly, they provide superior mechanical properties, withstanding extreme loads and pressures without compromising on structural integrity. Thirdly, due to their corrosion-resistant nature, HDG bolts and nuts are ideal for outdoor and marine projects where exposure to harsh elements is inevitable.

In construction, HDG bolts and nuts play a pivotal role in securing building components together, ensuring stability and safety. They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects

They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects hdg bolts and nuts. In the automotive industry, they are essential for engine assemblies, chassis connections, and suspension systems, providing strong and reliable connections.

The aerospace sector also benefits from HDG bolts and nuts due to their lightweight yet sturdy characteristics. They are crucial in aircraft manufacturing, satellite assembly, and rocket construction, where precision and durability are paramount. Similarly, in marine engineering, HDG fasteners resist saltwater corrosion, making them perfect for shipbuilding and offshore platform installations.

However, the effective use of HDG bolts and nuts necessitates proper handling and installation techniques. Tightening torque, cleaning, and inspection procedures should be diligently followed to ensure optimal performance and longevity.

In conclusion, HDG bolts and nuts are more than just connectors; they are the unsung heroes of modern engineering. Their robustness, corrosion resistance, and versatility make them indispensable tools in a multitude of industries. As technology advances and engineering requirements become more stringent, the importance of HDG bolts and nuts is only set to grow, solidifying their position in the realm of heavy-duty fasteners.

hdg bolts and nuts. In the automotive industry, they are essential for engine assemblies, chassis connections, and suspension systems, providing strong and reliable connections.

The aerospace sector also benefits from HDG bolts and nuts due to their lightweight yet sturdy characteristics. They are crucial in aircraft manufacturing, satellite assembly, and rocket construction, where precision and durability are paramount. Similarly, in marine engineering, HDG fasteners resist saltwater corrosion, making them perfect for shipbuilding and offshore platform installations.

However, the effective use of HDG bolts and nuts necessitates proper handling and installation techniques. Tightening torque, cleaning, and inspection procedures should be diligently followed to ensure optimal performance and longevity.

In conclusion, HDG bolts and nuts are more than just connectors; they are the unsung heroes of modern engineering. Their robustness, corrosion resistance, and versatility make them indispensable tools in a multitude of industries. As technology advances and engineering requirements become more stringent, the importance of HDG bolts and nuts is only set to grow, solidifying their position in the realm of heavy-duty fasteners.

They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects

They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects They are extensively used in bridge construction, highway infrastructure, and large-scale civil engineering projects hdg bolts and nuts. In the automotive industry, they are essential for engine assemblies, chassis connections, and suspension systems, providing strong and reliable connections.

The aerospace sector also benefits from HDG bolts and nuts due to their lightweight yet sturdy characteristics. They are crucial in aircraft manufacturing, satellite assembly, and rocket construction, where precision and durability are paramount. Similarly, in marine engineering, HDG fasteners resist saltwater corrosion, making them perfect for shipbuilding and offshore platform installations.

However, the effective use of HDG bolts and nuts necessitates proper handling and installation techniques. Tightening torque, cleaning, and inspection procedures should be diligently followed to ensure optimal performance and longevity.

In conclusion, HDG bolts and nuts are more than just connectors; they are the unsung heroes of modern engineering. Their robustness, corrosion resistance, and versatility make them indispensable tools in a multitude of industries. As technology advances and engineering requirements become more stringent, the importance of HDG bolts and nuts is only set to grow, solidifying their position in the realm of heavy-duty fasteners.

hdg bolts and nuts. In the automotive industry, they are essential for engine assemblies, chassis connections, and suspension systems, providing strong and reliable connections.

The aerospace sector also benefits from HDG bolts and nuts due to their lightweight yet sturdy characteristics. They are crucial in aircraft manufacturing, satellite assembly, and rocket construction, where precision and durability are paramount. Similarly, in marine engineering, HDG fasteners resist saltwater corrosion, making them perfect for shipbuilding and offshore platform installations.

However, the effective use of HDG bolts and nuts necessitates proper handling and installation techniques. Tightening torque, cleaning, and inspection procedures should be diligently followed to ensure optimal performance and longevity.

In conclusion, HDG bolts and nuts are more than just connectors; they are the unsung heroes of modern engineering. Their robustness, corrosion resistance, and versatility make them indispensable tools in a multitude of industries. As technology advances and engineering requirements become more stringent, the importance of HDG bolts and nuts is only set to grow, solidifying their position in the realm of heavy-duty fasteners. Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025