Exploring the Versatility and Applications of Hexagonal Nuts in Modern Engineering

Oct . 01, 2024 07:38 Back to list

Exploring the Versatility and Applications of Hexagonal Nuts in Modern Engineering

Understanding Hex Nuts A Comprehensive Overview

Hex nuts are an essential component in the world of fasteners and hardware. Widely used in various applications, these six-sided nuts play a crucial role in securing bolts and screws, ensuring that connections remain tight and stable under various conditions. In this article, we will delve into the characteristics, types, applications, and manufacturing processes of hex nuts, highlighting their importance in both everyday and industrial scenarios.

What Are Hex Nuts?

Hex nuts are fasteners that consist of a hexagonal block with a central hole, designed to be threaded onto a bolt. The six-sided shape allows for more effective gripping, enabling the nut to be tightened or loosened using a wrench. Typically made from materials such as steel, stainless steel, brass, or plastic, hex nuts are available in various sizes and grades, catering to different load and environmental requirements.

Types of Hex Nuts

Hex nuts can be classified into several types, each designed for specific applications

1. Standard Hex Nuts These are the most common type, used in general fastening applications. They feature a uniform design with standard threading.

2. Lock Nuts Lock nuts prevent loosening under vibration and torque. They are designed with features like nylon inserts (nyloc nuts) or contoured designs to secure their position.

3. Serrated Hex Nuts These nuts have serrated flanges that grip the material beneath them, providing enhanced resistance to loosening.

4. Slotted Hex Nuts Featuring slots on the sides, these nuts can be locked into place using a safety pin or wire, making them ideal for high-vibration environments.

5. Jam Nuts Thinner than standard hex nuts, jam nuts are used in conjunction with another nut to lock it in place by tightening them against each other.

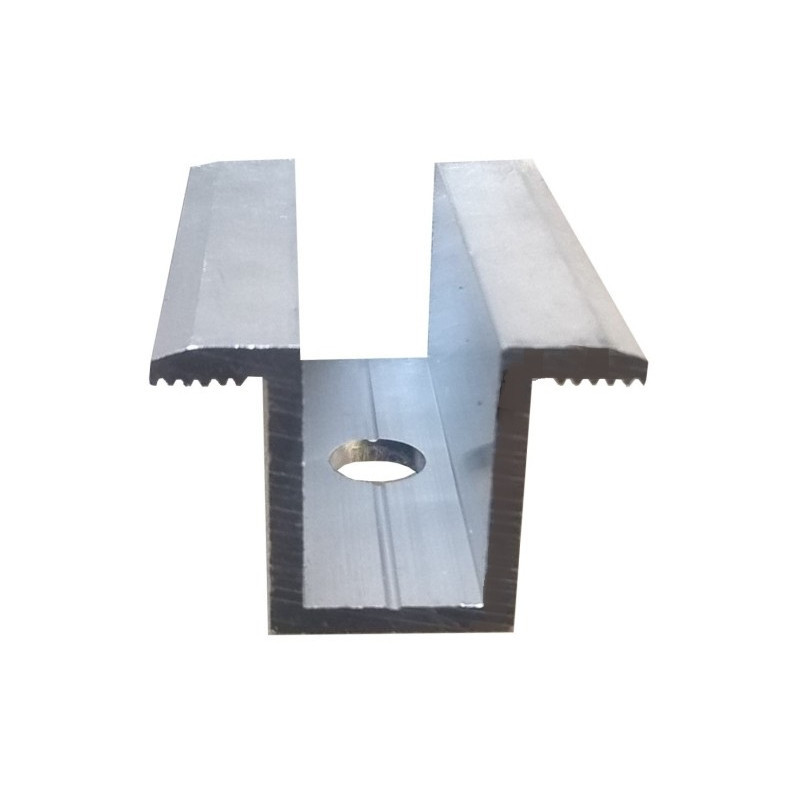

hex nut

Applications of Hex Nuts

Hex nuts are ubiquitous in various industries. In construction, they secure beams and structural components. In automotive manufacturing, they fasten engine components and frames. Similarly, in home improvement, they are frequently employed in assembling furniture or securing appliances. The versatility of hex nuts is evident in industries ranging from aerospace to electronics, where they ensure the reliability and safety of machinery and devices.

Their functionality extends beyond industrial use; for example, DIY enthusiasts and hobbyists rely on hex nuts in projects ranging from homemade furniture to robotics. Their availability in different materials allows users to choose the best option based on environmental conditions, such as exposure to moisture or chemicals.

Manufacturing Process

The manufacturing of hex nuts involves several stages, beginning with selecting the appropriate raw material. Steel nuts often undergo a heat treatment process to enhance their strength and durability. The typical manufacturing process includes

1. Cold Heading The raw material is shaped into a hexagonal form using a cold heading machine. 2. Threading The nuts are threaded using a tapping or threading machine, creating the necessary groove for the bolt.

3. Finishing This step may involve surface treatments like galvanization or coating to prevent corrosion and improve appearance.

4. Quality Control Finished products undergo quality checks to ensure they meet required standards, such as dimensional accuracy and material strength.

Conclusion

Hex nuts are more than just simple fasteners; they are engineered components vital for the stability and safety of countless structures and devices. Their design, versatility, and manufacturing processes reflect their importance in modern engineering and everyday life. As technology advances, the development of hex nuts continues to evolve, incorporating new materials and designs to meet the demands of various applications. Understanding hex nuts not only helps in selecting the right fastener for your needs but also appreciates the engineering behind this seemingly simple but essential component.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025