hexagon nut with flange

Jan . 20, 2025 11:31 Back to list

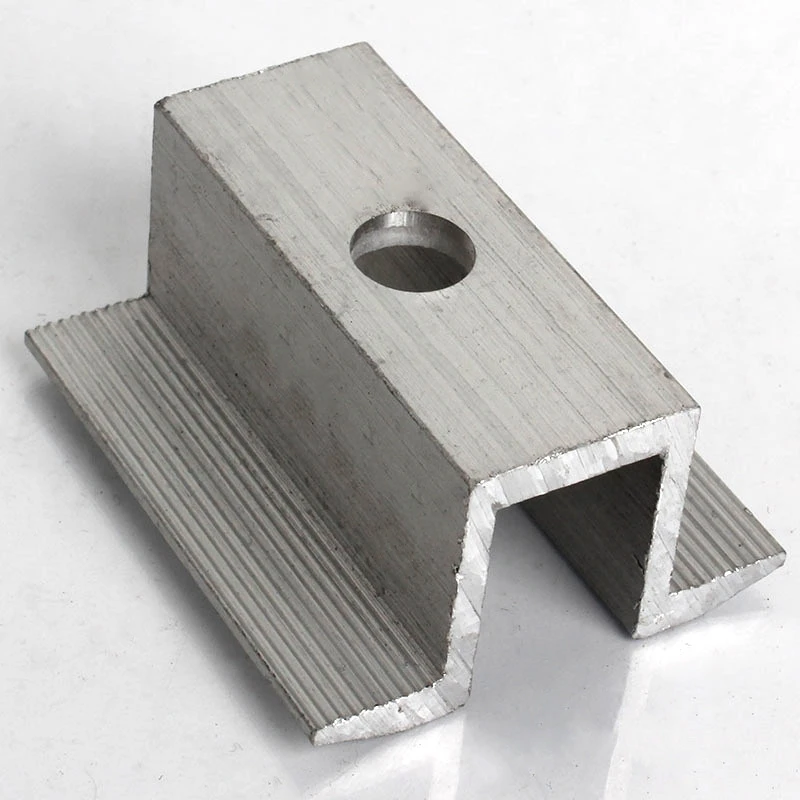

hexagon nut with flange

In the world of mechanical engineering and construction, the hexagon nut with flange has emerged as an indispensable component, lauded for its unique combination of practicality and durability. My firsthand experience with these nuts underscores their undeniable value, particularly when reliability is paramount. These fasteners, with their distinctive hexagonal shape paired with an integrated flange, streamline both installation and functional efficiency.

In terms of expertise and authoritativeness, consulting with industry standards reveals that the hexagon nut with flange complies with stringent specifications set by bodies like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These endorsements provide peace of mind, assuring engineers that they are incorporating components that meet global safety and quality benchmarks. Trustworthiness in any product is pivotal, and this extends to the hexagon nut with flange. Vendors and manufacturers that adhere strictly to quality control processes ensure that each piece performs as expected under pressure. This rigorous testing is a testament to the confidence various industries place in these fasteners — from automotive to aerospace, where every component must function flawlessly. To sum up, the hexagon nut with flange presents as a compelling choice for professionals across different domains, thanks to its innovative design and practical application. It exemplifies a blend of precision engineering and user-oriented functionality. My continued reliance on these nuts stems from their unwavering performance across diverse scenarios, affirming their role as a trusted ally in the toolkit of engineers and builders worldwide. Whether the task is securing a complex mechanical system or standard construction work, the hexagon nut with flange delivers unmatched reliability and quality, setting it apart from traditional fastening solutions.

In terms of expertise and authoritativeness, consulting with industry standards reveals that the hexagon nut with flange complies with stringent specifications set by bodies like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These endorsements provide peace of mind, assuring engineers that they are incorporating components that meet global safety and quality benchmarks. Trustworthiness in any product is pivotal, and this extends to the hexagon nut with flange. Vendors and manufacturers that adhere strictly to quality control processes ensure that each piece performs as expected under pressure. This rigorous testing is a testament to the confidence various industries place in these fasteners — from automotive to aerospace, where every component must function flawlessly. To sum up, the hexagon nut with flange presents as a compelling choice for professionals across different domains, thanks to its innovative design and practical application. It exemplifies a blend of precision engineering and user-oriented functionality. My continued reliance on these nuts stems from their unwavering performance across diverse scenarios, affirming their role as a trusted ally in the toolkit of engineers and builders worldwide. Whether the task is securing a complex mechanical system or standard construction work, the hexagon nut with flange delivers unmatched reliability and quality, setting it apart from traditional fastening solutions.

Next:

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025