hdg bolts

Oct . 31, 2024 05:52 Back to list

hdg bolts

Understanding HDG Bolts An Essential Component for Construction

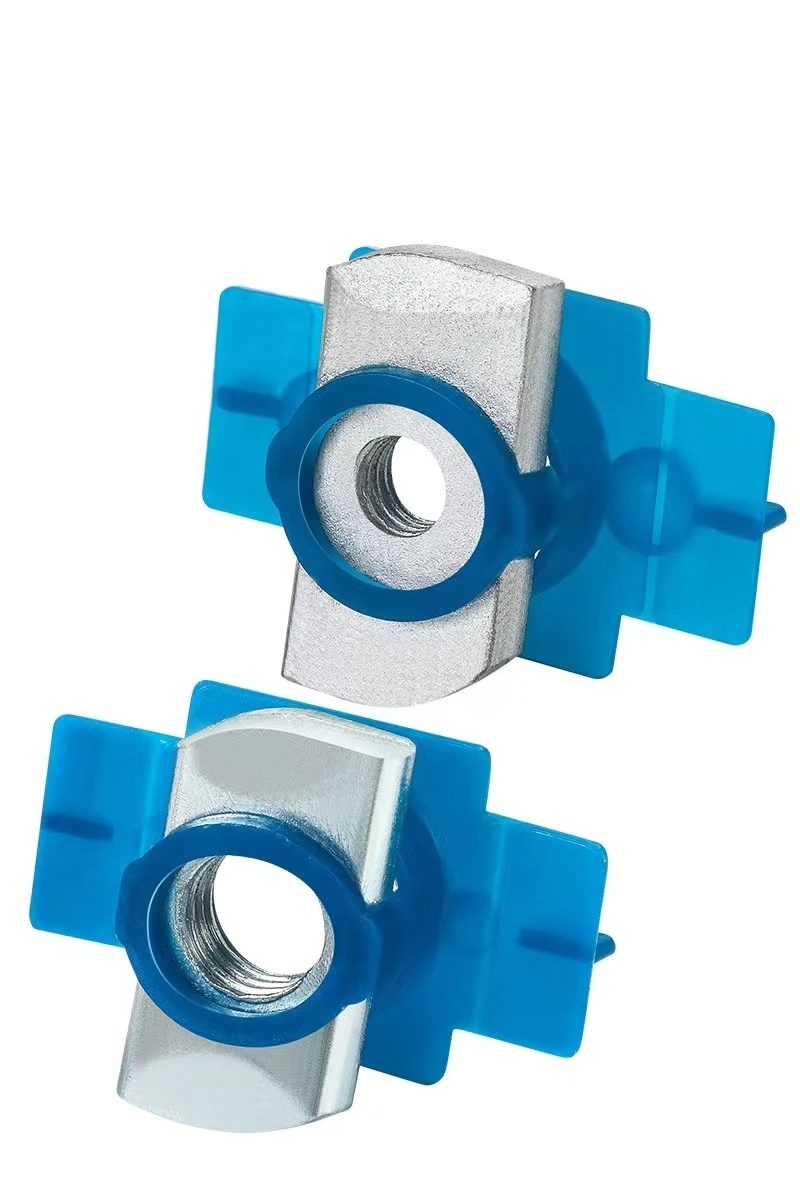

Hot-Dip Galvanized (HDG) bolts are a vital component in modern construction and engineering projects. Their unique properties and durability make them a preferred choice for a variety of applications, especially in environments where exposure to moisture and corrosive elements is a concern. This article delves into the significance, manufacturing process, applications, and benefits of HDG bolts.

What are HDG Bolts?

Hot-Dip Galvanized bolts are ordinary steel bolts that have undergone a galvanizing process, which involves coating the steel with a layer of zinc. This coating is achieved by immersing the bolts in molten zinc, leading to a metallurgical bond that ensures long-lasting protection against rust and corrosion. The result is a robust fastener that can withstand harsh environmental conditions.

Manufacturing Process

The process of hot-dip galvanization begins with surface preparation. This step is crucial, as any contaminants such as oil, dirt, or rust can affect the adhesion of the zinc coating. The bolts are cleaned using a combination of mechanical processes and chemical treatments. Once prepared, the bolts are immersed in a bath of molten zinc, which adheres to the steel and creates a protective layer. Finally, the bolts are quenched to ensure that the coating hardens properly. This whole process not only enhances the durability of the bolts but also extends their lifespan significantly.

Applications

HDG bolts are used across various industries, including construction, automotive, marine, and infrastructure. In construction, they are commonly found in steel structures, bridges, and buildings where the risk of corrosion is high. Their use guarantees structural integrity and safety over time. In the automotive industry, HDG bolts provide secure fastening solutions in vehicles exposed to harsh conditions. In marine applications, these bolts resist saltwater corrosion, making them ideal for docks and ships.

hdg bolts

Benefits of HDG Bolts

1. Corrosion Resistance The primary advantage of HDG bolts is their excellent resistance to corrosion, which is particularly important in outdoor and industrial environments. The zinc layer acts as a barrier, preventing moisture from reaching the steel.

2. Longevity Thanks to their enhanced durability, HDG bolts often last much longer than non-galvanized bolts, leading to lower maintenance costs and reduced need for replacements.

3. Cost-Effectiveness While the initial cost of HDG bolts may be higher than standard bolts, their longevity and reduced maintenance requirements make them a more cost-effective solution in the long run.

4. Environmental Safety Zinc is a non-toxic metal, making HDG bolts a suitable choice for applications in sensitive environments, such as those involving drinking water or food processing.

5. Aesthetic Appeal The shiny, bright finish of HDG bolts can be visually appealing, adding to the overall look of a project. This finish is also resistant to dirt and grime build-up.

Conclusion

In conclusion, HDG bolts are a crucial element in constructing durable and sustainable structures. Their corrosion resistance, longevity, and cost-effectiveness make them an ideal choice for a wide range of applications in various industries. As construction practices evolve and the demand for reliable materials increases, hot-dip galvanized bolts will undoubtedly remain an essential component in the engineering toolbox.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025