Understanding HDG Bolts and Their Applications in Construction Projects

Dec . 13, 2024 12:43 Back to list

Understanding HDG Bolts and Their Applications in Construction Projects

Understanding HDG Bolts A Comprehensive Overview

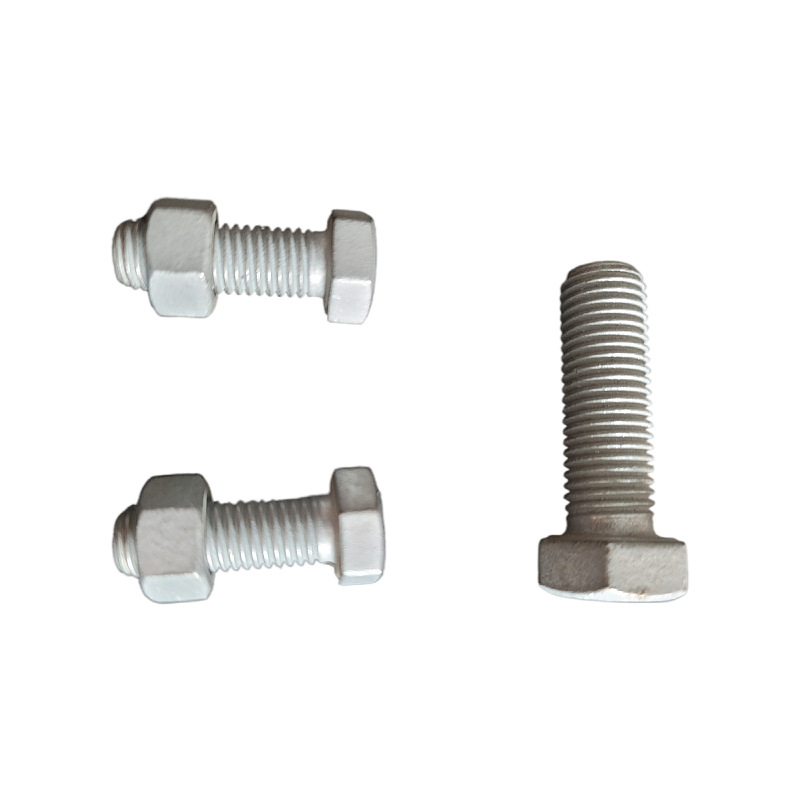

HDG bolts, or Hot-Dip Galvanized bolts, are a cornerstone in the field of construction and manufacturing. Their importance cannot be overstated, as they play a critical role in ensuring structural integrity and longevity in various applications. This article delves into the features, benefits, applications, and considerations surrounding HDG bolts.

What are HDG Bolts?

HDG bolts are conventional steel bolts that undergo a hot-dip galvanizing process, which involves immersing them in molten zinc. This process coats the steel with a thick layer of zinc, providing enhanced corrosion resistance. The zinc coating acts as a protective barrier, safeguarding the steel beneath from environmental factors that could lead to rust and degradation.

Benefits of HDG Bolts

1. Corrosion Resistance One of the most significant advantages of HDG bolts is their ability to resist corrosion. The zinc coating effectively protects the steel from moisture, chemicals, and other corrosive elements that are common in many environments.

2. Longevity Due to their robust nature against corrosion, HDG bolts have a significantly extended lifespan compared to non-galvanized counterparts. This durability translates to lower maintenance costs and fewer replacements over time.

3. Cost-Effectiveness Although the initial investment in HDG bolts may be higher than that of uncoated bolts, the long-term savings resulting from reduced maintenance and replacement make them a cost-effective choice in the long run.

4. Versatility HDG bolts can be used in a wide range of applications, from construction and heavy machinery to marine environments and infrastructure projects. Their adaptability makes them invaluable in many industries.

5. High Strength and Durability The steel used in HDG bolts ensures that they maintain high tensile and shear strength, making them suitable for load-bearing applications.

hdg bolts

Applications of HDG Bolts

HDG bolts find applications in various sectors, including

- Construction They are essential for steel structures, bridges, buildings, and other infrastructure owing to their strength and corrosion resistance. - Automotive Industry HDG bolts are used in vehicle manufacturing, particularly in parts exposed to harsh environments, such as undercarriages. - Marine Applications Given the high moisture levels and corrosive elements in marine environments, HDG bolts are extensively used in shipbuilding and offshore structures. - Utilities They are crucial in electrical and telecommunications infrastructure, where durability and longevity are paramount.

Considerations When Using HDG Bolts

While HDG bolts offer several advantages, there are also considerations to keep in mind

1. Compatibility It is essential to ensure that HDG bolts are compatible with the materials they are being used with, as certain combinations can lead to galvanic corrosion.

2. Installation Proper installation techniques should be followed to ensure that the bolts perform effectively. Incorrect tension or torque during installation can negate their benefits.

3. Cost Variability While HDG bolts are cost-effective in the long run, the initial cost can vary based on factors such as the size of the bolts, the thickness of the zinc coating, and market prices for steel.

4. Aesthetic Considerations The surface finish of HDG bolts may not always be suitable for visible applications without additional finishing processes.

In conclusion, HDG bolts are an integral component in various industries, offering excellent strength, corrosion resistance, and longevity. Proper selection and application of these bolts ensure that they meet the demands of the project, ultimately contributing to safer and more durable structures. Whether in construction, automotive, or marine applications, the innovative design of HDG bolts signifies a pivotal advancement in fastening technology, enhancing both functionality and reliability.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025