extra large penny washers for heavy-duty applications and

Nov . 13, 2024 19:39 Back to list

extra large penny washers for heavy-duty applications and

The Importance of Extra Large Penny Washers for Heavy-Duty Applications

In the world of construction and heavy-duty applications, selecting the right fastening components is crucial for ensuring safety, durability, and efficiency. Among these components, extra large penny washers stand out as essential tools that can significantly enhance the performance of various projects. This article delves into what extra large penny washers are, their advantages, and their applications in heavy-duty scenarios.

What Are Penny Washers?

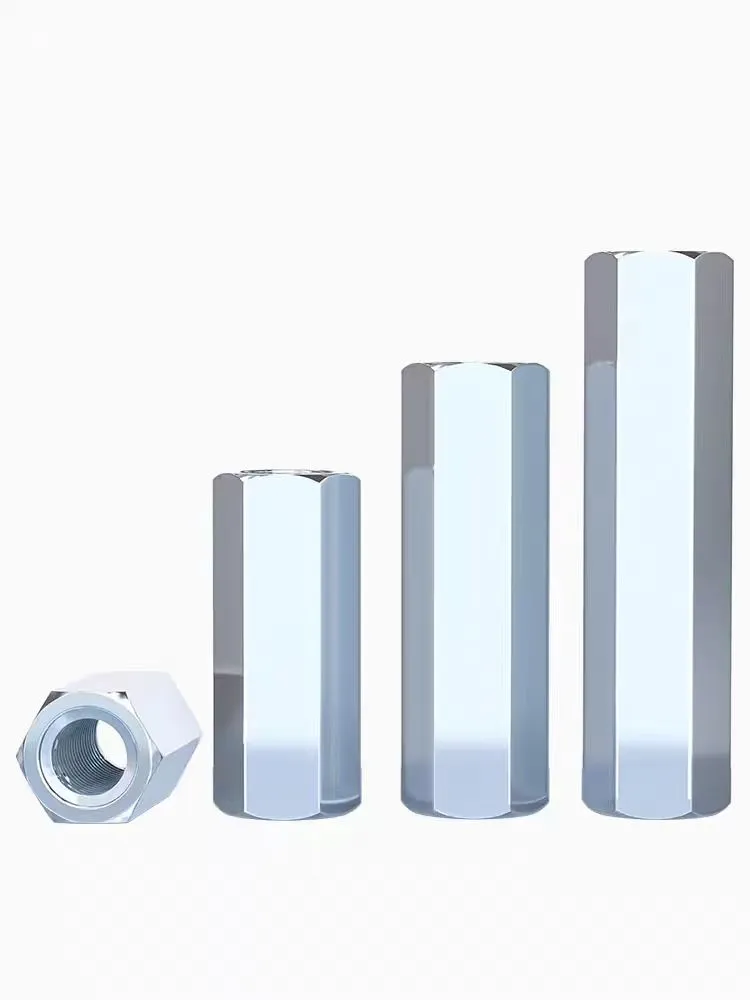

Penny washers, sometimes referred to as flat washers, are circular plates with a hole in the center, designed to distribute the load of a fastener (like a bolt or a screw) over a larger surface area. This design helps prevent the fastener from pulling through the material being fastened, which can lead to structural failure. The term penny washer is derived from their original size, which was roughly equivalent to a penny.

Extra large penny washers take this concept further by increasing the diameter of the washer. This additional size enhances their load-bearing capabilities, making them particularly useful in heavy-duty applications where high-stress conditions are prevalent.

Advantages of Extra Large Penny Washers

1. Load Distribution Extra large penny washers excel in distributing the load of fasteners over a wider area. This is especially important in heavy-duty applications where materials are subjected to intense forces. The increased surface area reduces the risk of material deformation and shear failure.

2. Prevention of Damage In many materials, like wood and metal, the use of standard washers can result in localized stress points. These stress points can lead to cracking or other forms of damage. The larger diameter of extra large penny washers minimizes these risks and provides more stability to the assembly.

3. Improved Grip The expansive surface area of extra large penny washers contributes to a more secure grip. This is particularly crucial in high-vibration environments, where standard washers may loosen over time. The enhanced grip ensures that the fastening remains tight and secure throughout the lifespan of the application.

4. Corrosion Resistance Many extra large penny washers are made from high-quality materials, such as stainless steel or coated metals, which offer superior resistance to corrosion. This feature extends their usability in harsh environmental conditions, such as construction sites or outdoor installations.

extra large penny washers for heavy-duty applications and

5. Versatility Extra large penny washers are highly versatile and can be used in various applications, including automotive, industrial machinery, construction, and plumbing. Their adaptability makes them a favorite among engineers and builders alike.

Applications in Heavy-Duty Scenarios

Heavy-duty applications often require components that can withstand substantial loads and environmental challenges. Here are a few scenarios where extra large penny washers are particularly advantageous

- Structural Connections In building construction, extra large penny washers are used to provide secure connections between beams and columns, ensuring that deck frames and roofing systems remain intact.

- Machinery Assembly In industrial settings, these washers are implemented in machinery assembly where high torque and shear forces are present. Their ability to distribute loads helps protect machinery and enhances operational efficiency.

- Outdoor Equipment For outdoor structures such as benches, tables, and fences, extra large penny washers safeguard against rust and ensure stability, helping these elements resist both time and weather.

- Automotive Applications In vehicles, these washers are employed to secure components that experience significant vibration and pressure, providing reliable performance over prolonged usage.

Conclusion

In conclusion, extra large penny washers are crucial components in heavy-duty applications, offering unparalleled advantages in terms of load distribution, protection against damage, improved grip, and corrosion resistance. Their versatile nature makes them invaluable tools for engineers, builders, and mechanics alike. By recognizing their importance, professionals can ensure the integrity and longevity of their projects, paving the way for safer and more robust constructions.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025