Exploring the Versatility and Applications of Slotted Channel Steel in Modern Construction Projects

Aug . 14, 2024 23:41 Back to list

Exploring the Versatility and Applications of Slotted Channel Steel in Modern Construction Projects

Understanding Slotted Channel Steel Properties, Applications, and Advantages

Slotted channel steel, often characterized by its distinctive slotted profile, is a versatile construction material widely used in various industries. Its design integrates strength and flexibility, making it an essential component in the construction and manufacturing sectors. This article will explore the properties, applications, and advantages of slotted channel steel, highlighting its significance in modern engineering.

Properties of Slotted Channel Steel

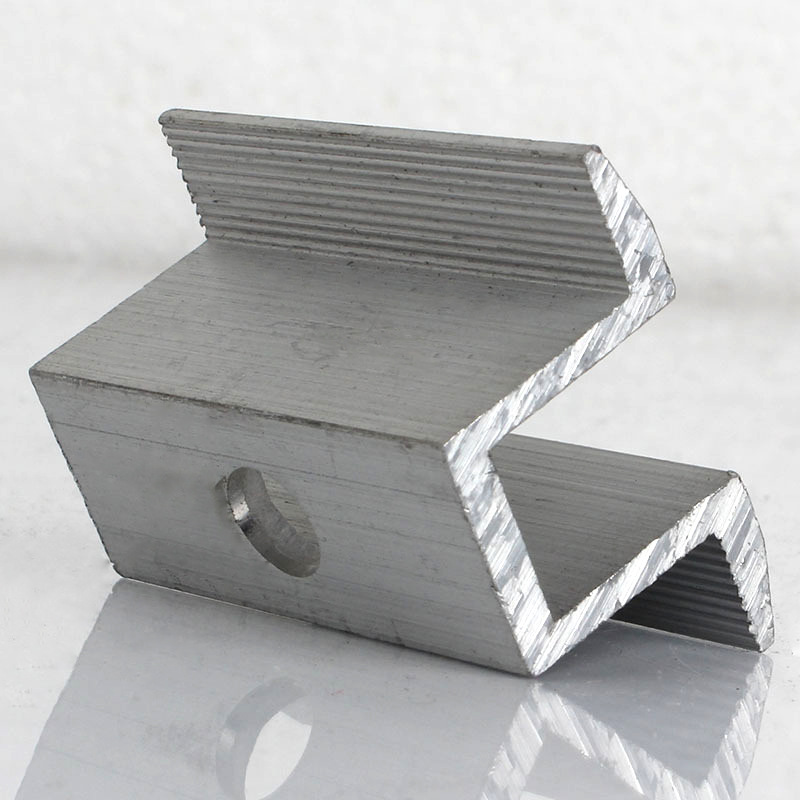

Slotted channel steel, also known as channel framing or C-channel, is fabricated from high-quality steel, which endows it with remarkable strength-to-weight ratios. The slotted design features elongated openings along the channel, allowing for easy attachment of other components, such as bolts, screws, or brackets. The shape of the channel provides excellent load-bearing capabilities, making it suitable for various structural applications.

Moreover, channel steel can be treated for corrosion resistance, allowing it to withstand harsh environmental conditions. It can also be finished in various ways, including galvanization and painting, which further enhances its durability and aesthetic appeal. The ability to manufacture slotted channel steel in different sizes and thicknesses provides flexibility in application, catering to specific project requirements.

Applications of Slotted Channel Steel

The versatility of slotted channel steel makes it suitable for numerous applications across diverse industries. In construction, it is frequently used in the framework of buildings, supporting shelves, wall brackets, and roof structures. The slotted design simplifies the installation process, enabling quicker adjustments and modifications, which is beneficial during the construction phase.

In manufacturing, slotted channel steel is employed in the production of conveyor systems, equipment frames, and modular workstations. Its adaptability to different configurations allows manufacturers to create efficient layouts for their operations, optimizing workflow and enhancing productivity.

slotted channel steel

Moreover, slotted channel steel is increasingly used in the installation of electrical and plumbing systems. Its slotted design facilitates cable management and the routing of pipes, ensuring a clean and organized setup. This feature is particularly useful in modern buildings, where maximizing space and maintaining aesthetics while ensuring functionality is crucial.

Advantages of Slotted Channel Steel

One of the primary advantages of slotted channel steel is its ease of use. The slotted holes simplify the assembly process, allowing for quick attachment and adjustments without the need for complex tools. This feature reduces labor costs and minimizes construction time, contributing to overall project efficiency.

The channel's lightweight nature, coupled with its strength, allows for easier handling and transportation, which is vital for large-scale projects. Furthermore, its cost-effectiveness makes it an attractive option for budget-conscious builders and manufacturers.

Another significant advantage is sustainability. Steel is a recyclable material, and the production of slotted channel steel can incorporate recycled content, contributing to environmentally friendly practices. Utilizing steel effectively reduces waste and promotes sustainable construction methods.

Conclusion

Slotted channel steel is a valuable material in contemporary construction and manufacturing, combining strength, flexibility, and ease of use. Its unique properties and versatile applications make it indispensable for various projects, from residential buildings to large-scale industrial operations. As industries continue to evolve and demand efficient, sustainable solutions, slotted channel steel will likely remain a foundational element in engineering and architectural designs. Its performance, cost-effectiveness, and adaptability solidify its position as a preferred choice in the modern construction landscape.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025