Durable Yellow Zinc Washers for Enhanced Corrosion Resistance and Reliable Performance in Various Applications

Jul . 27, 2024 04:00 Back to list

Durable Yellow Zinc Washers for Enhanced Corrosion Resistance and Reliable Performance in Various Applications

The Importance of Yellow Zinc Washers in Industry

In the realm of engineering and manufacturing, the little components often make a huge difference in the overall functionality and durability of a product. One such essential component is the washer, and among the various types available, yellow zinc washers are gaining significant attention in diverse applications. Their unique properties and advantages make them a preferred choice across many industries.

What are Yellow Zinc Washers?

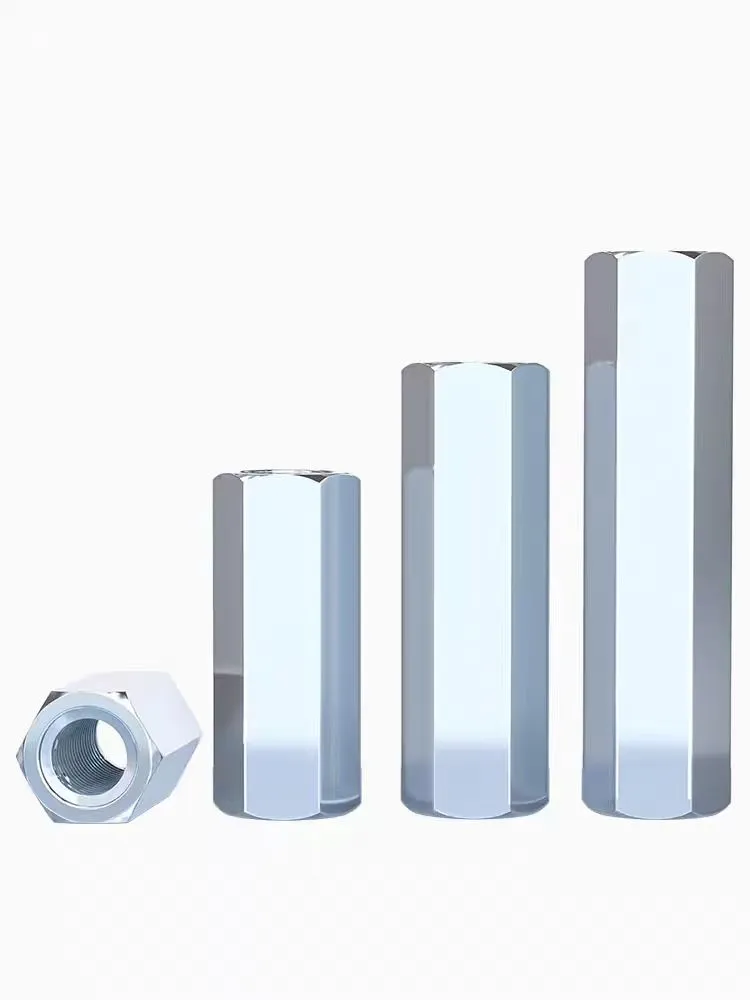

Yellow zinc washers are metal fasteners that often accompany screws and bolts to distribute the load over a larger area and prevent damage to the surface being fastened. The bright yellow hue comes from a zinc plating process that provides additional corrosion resistance. The zinc coating forms a protective barrier that inhibits rust and oxidation, extending the lifespan of the washer itself and the components it secures.

Advantages of Yellow Zinc Washers

1. Corrosion Resistance The primary advantage of yellow zinc washers is their excellent corrosion resistance. The zinc plating protects the underlying metal from moisture and environmental factors that can lead to rust and degradation. This makes yellow zinc washers particularly valuable in outdoor and marine applications, where exposure to water and salty air is a constant threat.

2. Durability The yellow zinc plating enhances the durability of the washers, allowing them to withstand high levels of stress and pressure. This durability is crucial in applications where components are subject to movement or vibration, as it reduces the risk of failure over time.

3. Aesthetic Appeal While functionality is key, aesthetics also play a role in many projects. The bright yellow finish of zinc-coated washers adds a visually appealing aspect to mechanical assemblies, making them suitable for visible applications in consumer products.

yellow zinc washers

4. Tensile Strength The inherent tensile strength of the materials used in manufacturing yellow zinc washers ensures that they can handle significant force without deforming. This strength is vital in applications such as automotive and aerospace, where safety and reliability are paramount.

5. Cost-Effective Compared to stainless steel washers, yellow zinc washers provide a more economical solution while still offering sound performance characteristics. This cost-effectiveness makes them an attractive alternative for bulk applications in various sectors, from construction to electronics.

Applications of Yellow Zinc Washers

The versatility of yellow zinc washers allows them to be used in a wide range of applications. In automotive manufacturing, they are commonly found in engine assemblies, frame components, and suspension systems. In construction, these washers are utilized in securing beams and framing elements to mitigate vibrations and ensure structural integrity. Additionally, their use in electronics and electrical applications ensures stable connections in devices and circuitry.

Moreover, yellow zinc washers are vital in the plumbing and HVAC industries, helping to secure fittings and flanges that must withstand fluctuations in temperature and pressure. Their reliability makes them indispensable in ensuring long-term performance in any assembly.

Conclusion

In conclusion, yellow zinc washers may seem like simple components, but they play a significant role in the reliability and longevity of various assemblies across multiple industries. Their corrosion resistance, durability, aesthetic appeal, and cost-effectiveness make them a favored choice for engineers and manufacturers. As industries continue to advance and demand more from their components, yellow zinc washers will undoubtedly remain a key player in the fastener market, contributing to innovation and quality in mechanical design and construction. Whether in heavy machinery or consumer electronics, their importance cannot be overstated.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025