Durable Heavy Metal Washers for Enhanced Performance and Reliability in Industrial Applications

Aug . 19, 2024 18:22 Back to list

Durable Heavy Metal Washers for Enhanced Performance and Reliability in Industrial Applications

The Rising Popularity of Heavy Metal Washers in Industrial Applications

In the ever-evolving landscape of manufacturing and engineering, heavy metal washers have emerged as indispensable components in a wide array of applications. These small yet mighty pieces of hardware play a crucial role in enhancing the performance, durability, and reliability of assembled products. From construction and automotive industries to aerospace and marine applications, heavy metal washers are gaining recognition for their strength and versatility.

Understanding Heavy Metal Washers

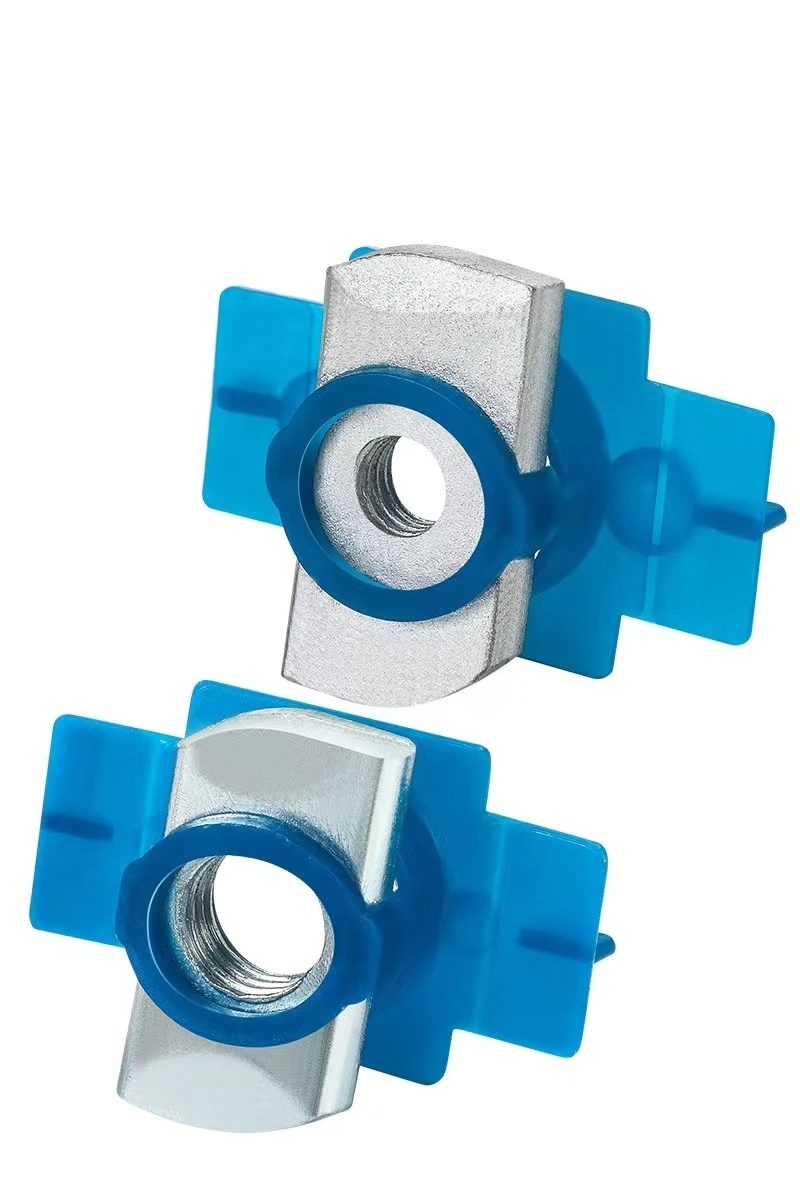

Heavy metal washers are flat discs, typically made from durable materials such as stainless steel, copper, or bronze. They are designed to be used with bolts, nuts, or screws to distribute the load of the fastener more evenly across the surface. This distribution helps to prevent damage to the material being fastened, reduces wear and tear, and increases the overall stability of the assembly.

The term heavy metal often refers to the substantial thickness and density of these washers, which contributes to their ability to withstand high loads and resist deformation. They are essential in applications where vibration and dynamic stress are prevalent, as they help prevent loosening and increase the longevity of the joint.

Applications Across Industries

Heavy metal washers find application in numerous industries. In the construction sector, they are used to secure structural components, ensuring that buildings and bridges remain stable under various loads. Their ability to withstand harsh weather conditions makes them ideal for outdoor constructions, where exposure to elements like rain, wind, and snow can affect the integrity of standard fasteners.

In the automotive industry, heavy metal washers are critical for numerous assembly components, including engines, suspensions, and body frames. By using these washers, manufacturers can ensure that vehicles maintain structural integrity and performance over time, even in the face of significant vibrational forces and thermal expansion.

heavy metal washers

The aerospace industry also benefits significantly from heavy metal washers. With stringent safety and reliability standards, aerospace engineers rely on these components to secure flight-critical systems effectively. Heavy metal washers contribute to the reliability of various aircraft parts, including engines, landing gear, and fuselage assemblies, ensuring the safety of both crew and passengers.

Advantages of Heavy Metal Washers

One of the primary advantages of heavy metal washers is their ability to distribute force more evenly, which reduces the chances of deformation at the fastening point. This characteristic is particularly vital in applications subject to fluctuating loads, as it minimizes the risk of failure.

Another significant benefit is their resistance to corrosion, especially when made from stainless steel or other high-performance materials. This resistance extends the lifespan of the assemblies in which they are used, making them a cost-effective choice in the long run.

Moreover, heavy metal washers can be manufactured in various sizes and thicknesses, allowing customization to meet specific application requirements. This flexibility ensures that engineers can select the appropriate washer for their unique needs, enhancing overall performance.

Conclusion

In conclusion, heavy metal washers are crucial components in a multitude of industrial applications. Their ability to provide stability, durability, and resistance to environmental factors makes them an essential part of everyday engineering solutions. As industries continue to embrace advanced materials and manufacturing techniques, the significance of heavy metal washers will only continue to grow, ensuring that they remain at the forefront of reliable and efficient assembly practices. Whether in construction, automotive, or aerospace, the reliance on these unsung heroes of hardware will undoubtedly persist, underpinning the strength of modern engineering.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025