Durable and Corrosion-Resistant Stainless Steel Fasteners for Various Applications and Industries

Aug . 13, 2024 02:08 Back to list

Durable and Corrosion-Resistant Stainless Steel Fasteners for Various Applications and Industries

Stainless Steel Fasteners An Essential Component in Modern Industry

Stainless steel fasteners are critical components that play an essential role in various industries, ranging from construction and automotive to aerospace and electronics. The importance of these fasteners cannot be overstated, as they provide the necessary strength, durability, and corrosion resistance required in a multitude of applications.

What are Stainless Steel Fasteners?

Stainless steel fasteners are mechanical devices that attach or secure two or more components together. These fasteners can include nuts, bolts, screws, washers, and rivets. The primary characteristic that distinguishes stainless steel fasteners from other types is their material composition. Stainless steel is an alloy that contains a minimum of 10.5% chromium, which enhances its corrosion resistance while providing a sleek, polished appearance.

Advantages of Stainless Steel Fasteners

1. Corrosion Resistance One of the most significant advantages of stainless steel is its inherent resistance to rust and corrosion. This property is crucial in environments exposed to moisture, chemicals, and extreme temperatures, making stainless steel fasteners ideal for marine applications, outdoor constructions, and food processing industries.

2. Strength and Durability Stainless steel fasteners exhibit excellent strength and durability, often outperforming their carbon steel counterparts. They can endure high levels of stress and strain, making them suitable for heavy-duty applications, such as bridges and high-rise buildings.

3. Aesthetic Appeal In addition to their functional benefits, stainless steel fasteners have a modern and attractive finish. This aesthetic quality makes them ideal for visible applications, such as interior design, where appearance can be just as important as functionality.

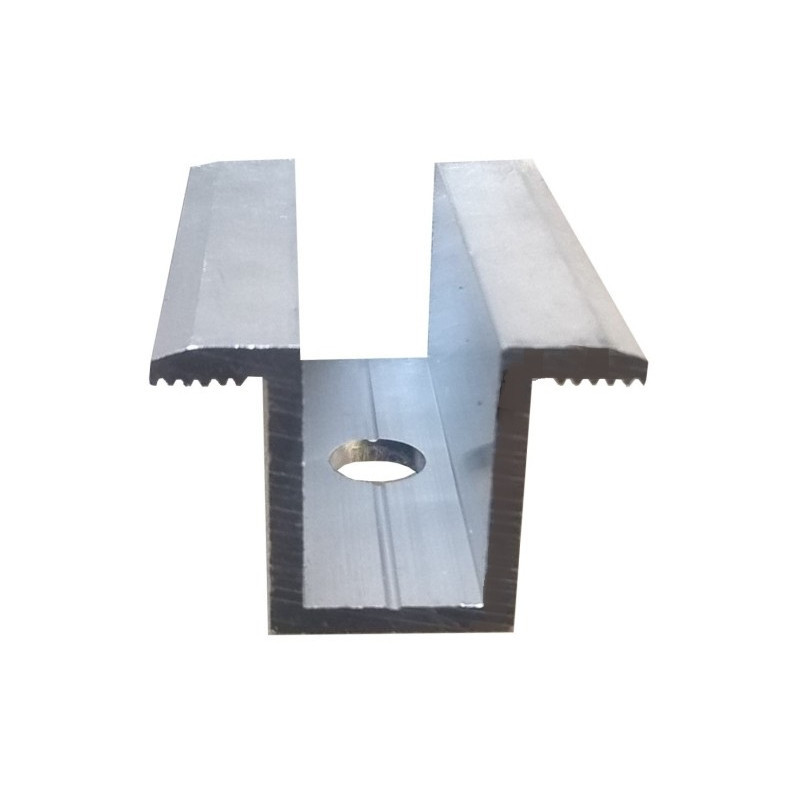

stainless steel fasteners

4. Low Maintenance Because of their resistance to corrosion and staining, stainless steel fasteners require minimal maintenance. This aspect not only saves time and labor costs but also contributes to the longevity of the structures they support.

5. Versatility Stainless steel fasteners are available in a wide range of sizes, grades, and styles, making them suitable for diverse applications. Different grades of stainless steel, such as 304 and 316, offer varying levels of corrosion resistance, allowing engineers and designers to choose the most appropriate fastener for their specific needs.

Applications of Stainless Steel Fasteners

The versatility of stainless steel fasteners enables their use across multiple sectors. In the automotive industry, these fasteners are used for everything from engine assemblies to body structures, ensuring the vehicles are secure and can withstand harsh conditions. In construction, stainless steel bolts and nuts are frequently utilized for structural frameworks, ensuring the reliability of buildings and bridges.

Moreover, in the food and pharmaceutical industries, where hygiene is paramount, stainless steel fasteners are preferred due to their non-reactive nature. They do not leach harmful chemicals, ensuring compliance with health and safety regulations.

Conclusion

In conclusion, stainless steel fasteners are indispensable in modern engineering and construction. Their unique combination of strength, corrosion resistance, aesthetic appeal, and low maintenance makes them the preferred choice for a wide array of applications. As technology advances and industries evolve, the demand for reliable, durable, and versatile fasteners like stainless steel will continue to grow, ensuring their role as a backbone of modern infrastructure and manufacturing remains solid for years to come. By choosing stainless steel fasteners, manufacturers and builders not only enhance the performance and safety of their products but also contribute to a more sustainable and efficient industrial landscape.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025