custom fastener

Jan . 10, 2025 08:53 Back to list

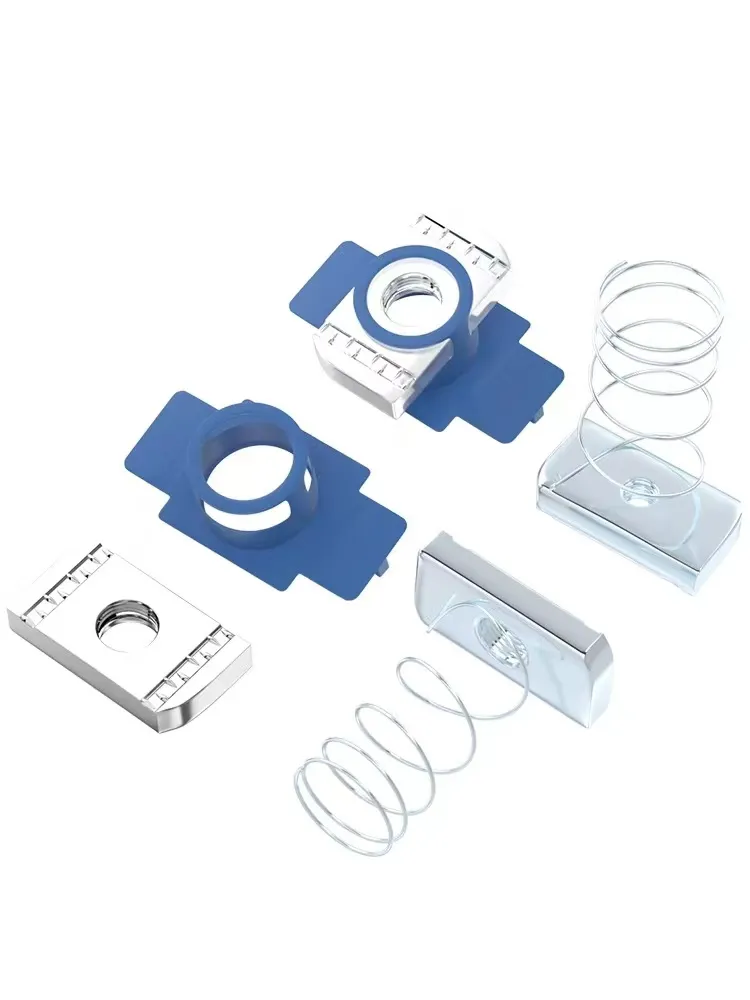

custom fastener

Crafted with precision and purpose, custom fasteners play an indispensable role in various industries. These specialized components, though often small and understated, are critical to the structural integrity and performance of countless products. Their design goes beyond standard specifications, providing solutions that are as unique as the challenges they meet. Delving into the realm of custom fasteners uncovers a world where expertise meets innovation to create items tailored to specific applications, ensuring reliability and efficiency.

Trustworthiness comes into play through transparent communication and uncompromised quality assurance practices. Manufacturers of custom fasteners pride themselves on their meticulous quality controls at every stage of production. This might include non-destructive testing methods to ensure structural integrity or conducting fatigue assessments to understand long-term material performance. It’s the rigorous testing protocols that assure clients, providing peace of mind that every fastener will perform impeccably under specified conditions. In a world that increasingly demands tailor-made solutions, the necessity for custom fasteners remains undeniable. As industries grow more complex and machinery more advanced, the demand for components that can withstand unique and demanding situations grows with it. The custom fastener thus becomes more than a mere mechanical part—it transforms into a pivotal player in the orchestration of larger systems. Recognized not just for their functional attributes, custom fasteners symbolize a commitment to quality and innovation that anchors the very fabric of modern engineering solutions. By embedding themselves as trusted advisers, these specialists provide comprehensive support and shared knowledge, preemptively addressing potential issues during the design phase. This partnership approach ensures that every fastener produced is fit for purpose, reflecting both a deep-seated understanding of industry needs and a proactive stance towards achieving excellence. Custom fasteners, in essence, are a testament to how wise manufacturing choices can significantly elevate both product performance and customer satisfaction in any field.

Trustworthiness comes into play through transparent communication and uncompromised quality assurance practices. Manufacturers of custom fasteners pride themselves on their meticulous quality controls at every stage of production. This might include non-destructive testing methods to ensure structural integrity or conducting fatigue assessments to understand long-term material performance. It’s the rigorous testing protocols that assure clients, providing peace of mind that every fastener will perform impeccably under specified conditions. In a world that increasingly demands tailor-made solutions, the necessity for custom fasteners remains undeniable. As industries grow more complex and machinery more advanced, the demand for components that can withstand unique and demanding situations grows with it. The custom fastener thus becomes more than a mere mechanical part—it transforms into a pivotal player in the orchestration of larger systems. Recognized not just for their functional attributes, custom fasteners symbolize a commitment to quality and innovation that anchors the very fabric of modern engineering solutions. By embedding themselves as trusted advisers, these specialists provide comprehensive support and shared knowledge, preemptively addressing potential issues during the design phase. This partnership approach ensures that every fastener produced is fit for purpose, reflecting both a deep-seated understanding of industry needs and a proactive stance towards achieving excellence. Custom fasteners, in essence, are a testament to how wise manufacturing choices can significantly elevate both product performance and customer satisfaction in any field.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025