corrugated fasteners

Jan . 13, 2025 15:28 Back to list

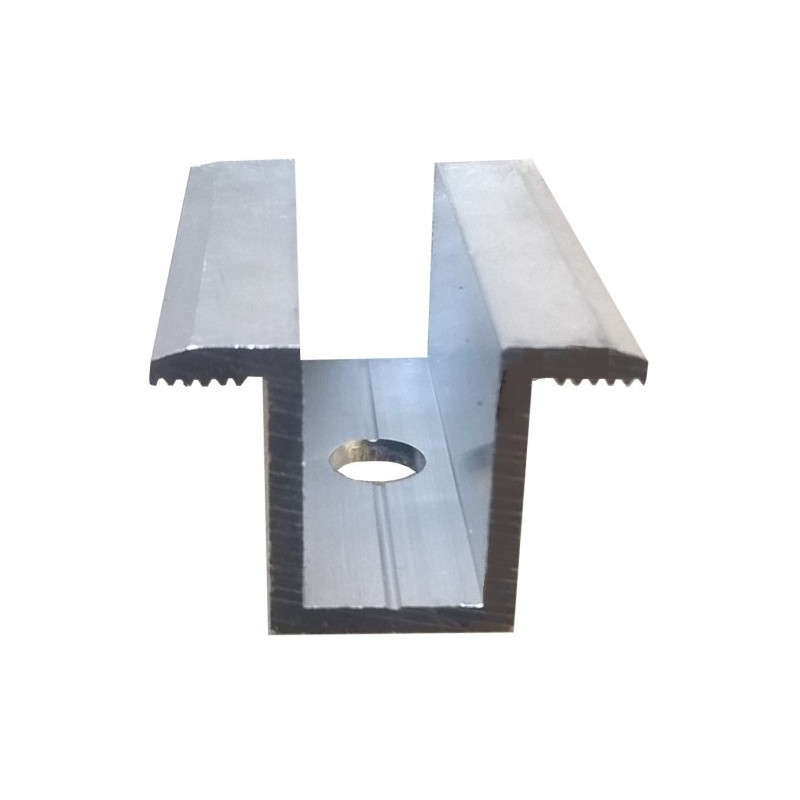

corrugated fasteners

Corrugated fasteners, often overlooked in the realm of construction and carpentry, are critical components for creating strong and lasting joints. Their distinctive design and engineering cater to applications that demand reinforced stability, unrivaled resilience, and longevity. To appreciate the significance of corrugated fasteners, we must delve into their material composition, specific applications, and the myriad benefits they provide to both professionals and DIY enthusiasts.

In addition to the functional benefits, understanding the impact of corrugated fasteners on environmental sustainability is equally crucial. Many manufacturers have adopted eco-friendly production practices, utilizing recyclable materials and minimizing waste during production processes. This aligns with the growing industry trend towards sustainable building practices, highlighting corrugated fasteners as not just effective, but responsible choices. The expertise in selecting and using corrugated fasteners can make a marked difference in project outcomes. Builders and hobbyists should consider the specific requirements of their projects when choosing fasteners, including the load demands, environmental conditions, and material compatibility. Consulting with industry experts or conducting thorough research can result in informed decisions, fostering success across various applications. For those new to using corrugated fasteners, starting with small-scale projects can build familiarity and confidence. Most importantly, safety precautions should always be a priority. Proper eye and hand protection, alongside using the correct tools, ensure a safe and effective fastening process. In sum, corrugated fasteners, with their proven reliability, versatility, and efficiency, continue to be indispensable in both professional and personal woodworking domains. Their contribution to the structural integrity of wood-based projects cannot be overstated, securing them as a staple in the toolkit of seasoned carpenters and aspiring builders alike. By recognizing their value and integrating them wisely, users can achieve craftsmanship that stands the test of time, bolstering the trustworthiness of their projects.

In addition to the functional benefits, understanding the impact of corrugated fasteners on environmental sustainability is equally crucial. Many manufacturers have adopted eco-friendly production practices, utilizing recyclable materials and minimizing waste during production processes. This aligns with the growing industry trend towards sustainable building practices, highlighting corrugated fasteners as not just effective, but responsible choices. The expertise in selecting and using corrugated fasteners can make a marked difference in project outcomes. Builders and hobbyists should consider the specific requirements of their projects when choosing fasteners, including the load demands, environmental conditions, and material compatibility. Consulting with industry experts or conducting thorough research can result in informed decisions, fostering success across various applications. For those new to using corrugated fasteners, starting with small-scale projects can build familiarity and confidence. Most importantly, safety precautions should always be a priority. Proper eye and hand protection, alongside using the correct tools, ensure a safe and effective fastening process. In sum, corrugated fasteners, with their proven reliability, versatility, and efficiency, continue to be indispensable in both professional and personal woodworking domains. Their contribution to the structural integrity of wood-based projects cannot be overstated, securing them as a staple in the toolkit of seasoned carpenters and aspiring builders alike. By recognizing their value and integrating them wisely, users can achieve craftsmanship that stands the test of time, bolstering the trustworthiness of their projects.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025