Innovative Fastening Solutions for Enhanced Efficiency and Reliability in Construction Projects

Oct . 18, 2024 19:38 Back to list

Innovative Fastening Solutions for Enhanced Efficiency and Reliability in Construction Projects

Understanding Cleco Fasteners A Key Tool in Manufacturing and Assembly

In the world of manufacturing and assembly, precision and efficiency are paramount. Among the various tools and components used to achieve these goals, Cleco fasteners have carved out a significant niche. These versatile fasteners are particularly popular in the aerospace, automotive, and construction industries, where temporary fastening solutions are often required.

What Are Cleco Fasteners?

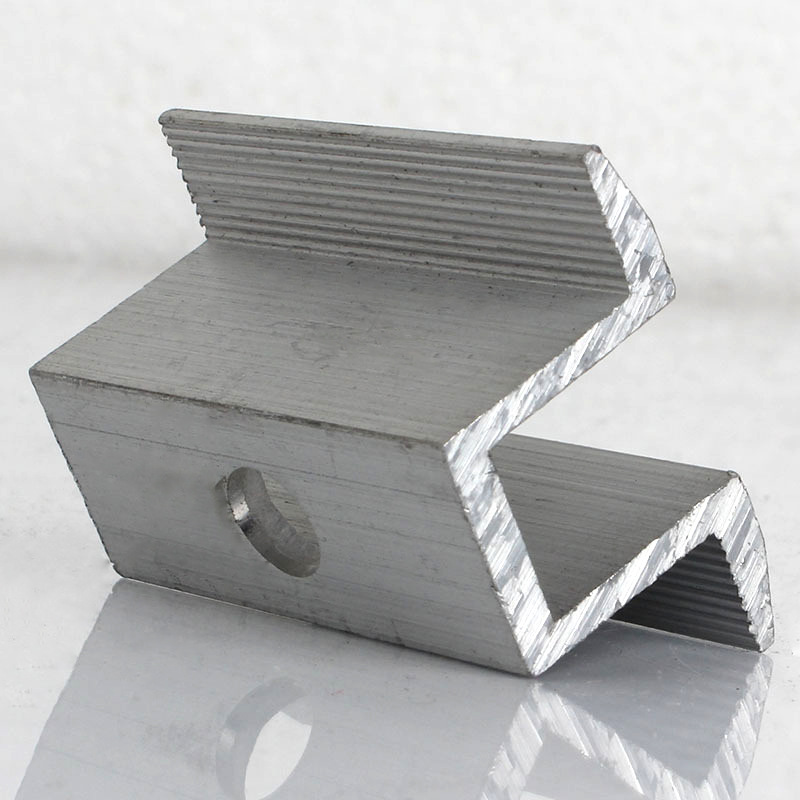

Cleco fasteners, also known as Cleco clamps or Cleco pins, are temporary fasteners that are used to hold two or more pieces of material together. They come in various sizes and styles, but the most common type resembles a rivet with a slender, cylindrical shape. The mechanism consists of a metal pin with a spring-loaded head that locks into place, allowing for quick and easy application and removal. This design makes Cleco fasteners ideal for situations where a permanent fastener is not yet appropriate.

Applications of Cleco Fasteners

One of the primary applications for Cleco fasteners is in the assembly of aircraft and vehicles. During the initial assembly phase, components may need to be held in place for drilling, welding, or machining. Clecos allow workers to temporarily secure parts without permanently attaching them. This flexibility is crucial, as it enables technicians to make adjustments and alignments before final assembly and permanent fastening.

In addition to aerospace and automotive uses, Cleco fasteners are also employed in metalworking, construction, and general manufacturing. For example, they are often used to assemble jigs and fixtures, provide a means of holding pieces together while undergoing further machining operations, or assist in the layout of components before final welding.

cleco fasteners

Benefits of Using Cleco Fasteners

The advantages of Cleco fasteners are numerous. Firstly, they save time and labor. Unlike traditional fastening methods, which can require multiple steps and tools, Clecos can be easily installed and removed in seconds. This efficiency translates to lower labor costs and faster project completion.

Furthermore, Cleco fasteners are incredibly versatile. They can accommodate a wide range of materials, including metal, plastic, and composite materials. This versatility ensures that they are suitable for a variety of applications, from delicate assemblies to heavy-duty construction projects.

The ability to quickly adjust or remove fasteners is another significant benefit. In industries where precise measurements are critical, Clecos allow workers to ensure perfect alignment before committing to a permanent fastening solution.

Conclusion

In summary, Cleco fasteners play a crucial role in the manufacturing and assembly sectors, particularly where temporary fastening solutions are required. Their ease of use, efficiency, and versatility make them an indispensable tool for engineers, technicians, and manufacturers alike. As industries continue to evolve and demand more efficient solutions, the popularity and application of Cleco fasteners are likely to grow. With ongoing advancements in materials and design, these fasteners will remain a key component in ensuring the seamless assembly of complex products across various sectors. Whether it's holding components together during assembly or aiding in the fabrication process, Cleco fasteners are a testament to the ingenuity of modern manufacturing techniques.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025