Ceramic Ferrule Applications in Stud Welding Technology and their Benefits

Dec . 01, 2024 23:10 Back to list

Ceramic Ferrule Applications in Stud Welding Technology and their Benefits

The Role of Ceramic Ferrules in Stud Welding

Stud welding is a widely used technique in various industrial applications, allowing for the efficient joining of fasteners to a range of substrates, particularly metals. At the heart of this process is the stud, a short metal rod with a smooth cylindrical body, which is welded to a base material, often without the need for drilling or extensive preparation. An essential component of efficient stud welding is the ceramic ferrule, which plays a crucial role in ensuring the quality and integrity of the weld.

Understanding Ceramic Ferrules

Ceramic ferrules are cylindrical covers made from high-quality ceramic materials that are designed to enhance the stud welding process. They are used to contain the molten metal created during the welding process and to protect it from atmospheric contamination. These ferrules also serve to focus the heat generated during the welding process, ensuring a clean and effective weld.

Advantages of Using Ceramic Ferrules

1. Heat Resistance One of the primary benefits of ceramic ferrules is their ability to withstand high temperatures. During stud welding, the heat generated is substantial. Ceramic materials are inherently resistant to thermal shock, making them an ideal choice for applications where extreme temperatures are a factor.

2. Cleaner Welds The use of ceramic ferrules results in cleaner welds with less spatter. The ferrule helps to contain and control the molten metal, minimizing the risk of contamination from external elements such as oxygen or moisture that could otherwise compromise the weld.

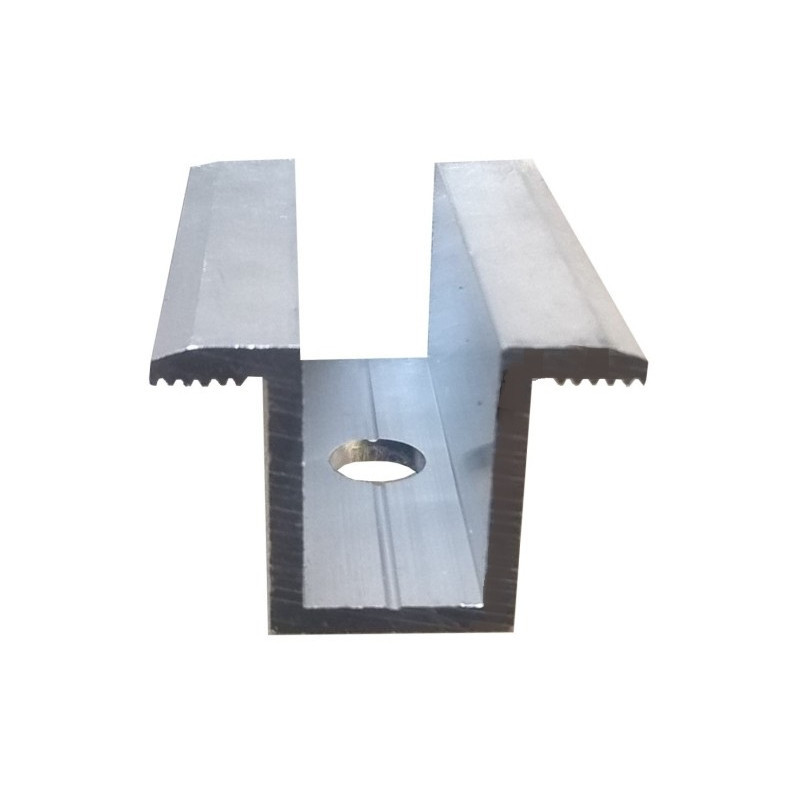

ceramic ferrule for stud welding

3. Improved Weld Quality By focusing the heat and providing a stable environment for the welding process, ceramic ferrules contribute to consistent weld quality. This is particularly important in applications where the integrity of the joint is critical, such as in construction, automotive, and aerospace industries.

4. Versatility Ceramic ferrules are versatile and can be used with various stud types and materials. This adaptability allows engineers and welders to employ them in a wide range of projects, accommodating different specifications and requirements.

5. Cost-Effectiveness While there may be an initial investment in ceramic ferrules, they ultimately contribute to reducing production costs. The improved quality of welds can decrease the likelihood of rework and minimizing material waste due to inferior welds enhances overall efficiency and cost-effectiveness.

Applications in Various Industries

Ceramic ferrules are utilized across diverse sectors where stud welding is implemented. In the construction sector, they are essential for joining metal studs to steel structures, facilitating robust and durable connections. In the automotive industry, manufacturers use them to weld fasteners for various components, including frames and exhaust systems. The aerospace sector also benefits from ceramic ferrules, where the strength and reliability of welded joints are imperative for safety.

Conclusion

In conclusion, ceramic ferrules play an invaluable role in the stud welding process, contributing significantly to weld quality and efficiency. Their heat resistance, ability to produce cleaner welds, and versatility make them an indispensable tool in the welding industry. As technology continues to evolve, the importance of high-quality components such as ceramic ferrules will only grow, ensuring that industries can meet the demands for strong and reliable welded joints. As manufacturers search for ways to enhance productivity while maintaining high standards of quality, the role of ceramic ferrules in stud welding will remain central to achieving these goals.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025