Overview of A325 Bolt Specifications and Standards for Structural Applications

Nov . 06, 2024 14:49 Back to list

Overview of A325 Bolt Specifications and Standards for Structural Applications

Understanding A325 Bolt Specifications

The A325 bolt is a critical component in construction and engineering, recognized for its structural integrity and reliability. These bolts, governed by the ASTM A325 standard, are commonly used in steel structures, including bridges, buildings, and various other infrastructure projects. This article delves into the specifications, applications, and importance of A325 bolts in maintaining structural safety.

Specifications Overview

ASTM A325 outlines the requirements for high-strength bolts, typically made from carbon steel. These bolts are often used in structural assemblies and are classified into several grades based on their strength and mechanical properties. The key specifications include the following

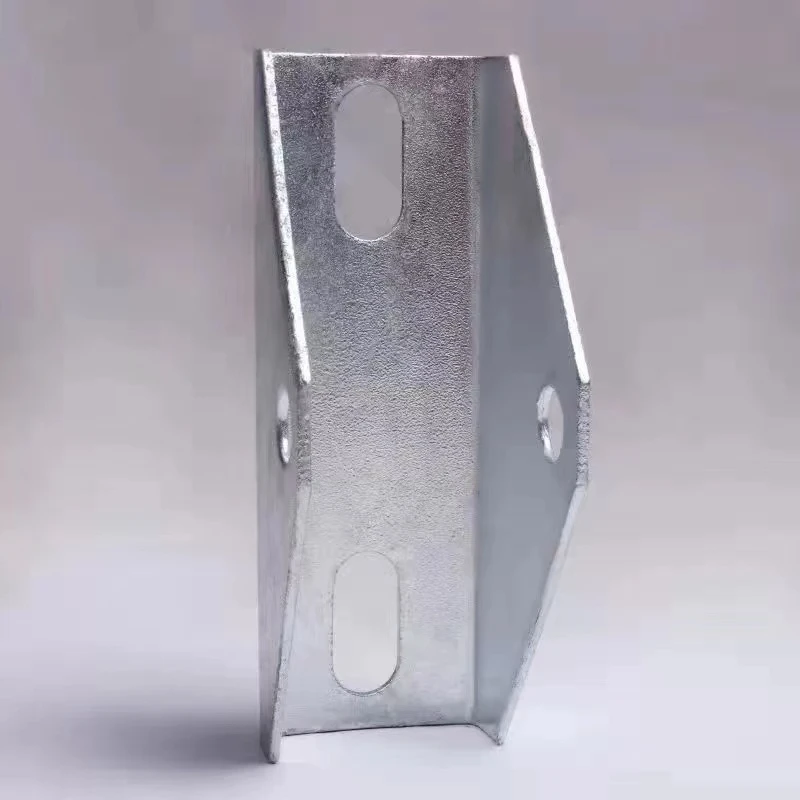

1. Material A325 bolts are generally made from medium carbon steel, which may be heat-treated to enhance strength. They also can be manufactured with or without a coating, such as galvanization, to improve corrosion resistance.

2. Grade There are different grades of A325 bolts, the most common being Grade A325, which denotes the mechanical properties and tensile strength. Grade A325 bolts must achieve a minimum tensile strength of 120 ksi (kilopounds per square inch).

3. Sizes A325 bolts come in various diameters, typically ranging from 1/2 inch to 1-1/2 inches. The length of the bolts can also vary, allowing for flexibility in different applications.

5. Thread Types These bolts are usually manufactured with coarse threads, enabling easier engagement during assembly, especially in large structural joints.

6. Tensile and Yield Strength A325 bolts typically display a yield strength of 72 ksi (for bolts with a nominal diameter of 1 inch or less) and higher for larger diameters. These properties are critical for ensuring that bolts can withstand the forces exerted during loading conditions.

a325 bolt spec

Applications

Due to their high strength, A325 bolts play a pivotal role in many structural applications

- Steel Construction A325 bolts are extensively utilized in the construction of buildings and bridges, where they secure components together, ensuring stability and safety.

- Industrial Applications These bolts are also common in heavy machinery and manufacturing settings, where durable connections are essential for operational efficiency.

- Infrastructure Projects From highways to rail systems, A325 bolts are integral in assembling components that support substantial loads and vibrations.

Importance of Proper Specifications

Using the correct specifications for A325 bolts is paramount. Proper selection ensures that the bolts will perform effectively under expected loading conditions. Inadequate bolt selection can lead to structural failures, posing safety risks and resulting in costly repairs or replacements.

Moreover, adhering to the A325 specifications promotes standardization within the industry, facilitating interoperability among manufacturers and construction teams. This standardization not only helps ensure quality and reliability but also provides assurance to engineers and builders that the materials they are using meet stringent safety requirements.

Conclusion

In conclusion, A325 bolts are essential components in modern construction, providing the strength and reliability necessary for maintaining structural integrity. Understanding their specifications, from material properties to applications, is crucial for engineers, architects, and builders. By adhering to ASTM A325 standards, the industry can ensure that the structures we depend on remain safe and durable for years to come. Whether it's in the construction of skyscrapers or bridges, A325 bolts play a vital role in our infrastructure, making their specifications an essential consideration in any engineering project.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025