5% 2016 Shear Bolt Specifications and Applications in Mechanical Engineering

Dec . 06, 2024 12:01 Back to list

5% 2016 Shear Bolt Specifications and Applications in Mechanical Engineering

Understanding the 5% 2016 Shear Bolt A Comprehensive Overview

Shear bolts play a critical role in various mechanical applications, especially those requiring safety mechanisms or force limitations. Among the different grades and specifications, the 5% 2016 shear bolt stands out due to its unique properties and usability in various industrial contexts. This article explores the significance, specifications, advantages, and applications of the 5% 2016 shear bolt.

What is a Shear Bolt?

A shear bolt, commonly used in engineering and manufacturing, is designed to fail or break under a specific load, protecting other components or systems from damage. The precise nature of its failure makes it an essential part of safety-critical systems, ensuring that components do not sustain irreversible damage during overload situations. Based on their construction and application, shear bolts can be made from different materials, each providing specific advantages in terms of strength, durability, and resistance to environmental factors.

The Specification of the 5% 2016 Shear Bolt

The term 5% 2016 in shear bolts typically refers to a particular material specification, likely alluding to the type of steel alloy used and the mechanical properties associated with it. The 5% can indicate the amount of yield or deviation expected in the material when subjected to shear forces. The 2016 portion likely references an alloy standard, perhaps indicating a specific series of aluminum or steel that possesses excellent shear resistance and tensile strength.

Common characteristics of shear bolts, including the 5% 2016 specification, include

1. Yield Strength The yield strength must be known to predict at what point the bolt will fail. For the 5% 2016 shear bolt, this measure is crucial as it determines how much load the bolt can withstand before shear failure occurs.

2. Material Composition The composition of the 2016 alloy typically includes significant amounts of copper, which enhances the strength-to-weight ratio, making it ideal for applications requiring lightweight but strong materials.

3. Dimensional Standards The dimensions of the shear bolt must comply with industry standards to ensure compatibility with various machinery and systems.

4. Surface Finish The surface finish of the bolt can influence its performance, especially in corrosive environments. A properly treated surface prevents premature failure due to corrosion.

Advantages of 5% 2016 Shear Bolts

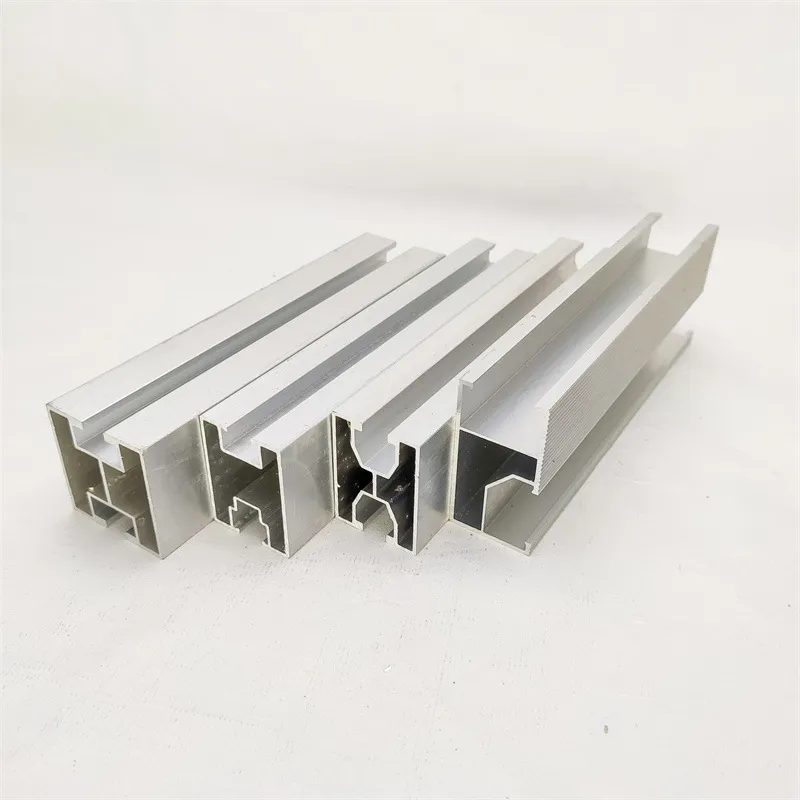

5 16 shear bolt

1. Reliability The design characteristics of the 5% 2016 shear bolt ensure reliable performance, particularly in applications where safety is paramount. The predictable failure mode allows for controlled maintenance and planning.

2. Strength-to-Weight Ratio With an advantageous strength-to-weight ratio, components designed with these bolts can be lighter without compromising performance, enabling more efficient designs in automotive and aerospace industries.

3. Cost-Effectiveness Although high-quality materials typically come at a premium, the long-term savings generated by reduced damage to other equipment and decreased maintenance needs make the 5% 2016 shear bolt a cost-effective solution in many applications.

4. Versatile Application These shear bolts can be used in a wide range of industries, from automotive to machinery and even in construction, owing to their robust properties.

Applications of 5% 2016 Shear Bolts

The applications of 5% 2016 shear bolts are diverse and reflect their mechanical strength and reliability. Here are a few key areas where they are commonly used

- Automotive Engineering In automotive design, shear bolts are often utilized in safety mechanisms, such as in clutches and other components where controlled failure is crucial in case of overload.

- Industrial Machinery These bolts are frequently used in various industrial applications where machinery operates under load and must have parts that can give way under excessive stress.

- Construction Equipment Equipment that operates under load or risks impact can benefit from the use of shear bolts, as they help protect vital components from catastrophic failure.

Conclusion

The 5% 2016 shear bolt represents a robust and reliable solution in engineering mechanics. Its unique specifications and properties make it an indispensable component across multiple industries. By ensuring predictable performance under stress, shear bolts like the 5% 2016 not only enhance safety but also contribute to the longevity and efficiency of various machines and structures. As technology advances, the demand for such specialized components will likely continue to grow, highlighting the enduring importance of shear bolts in industrial applications worldwide.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025