4mm flange nut

Dec . 05, 2024 18:29 Back to list

4mm flange nut

Understanding 4mm Flange Nuts Functionality and Applications

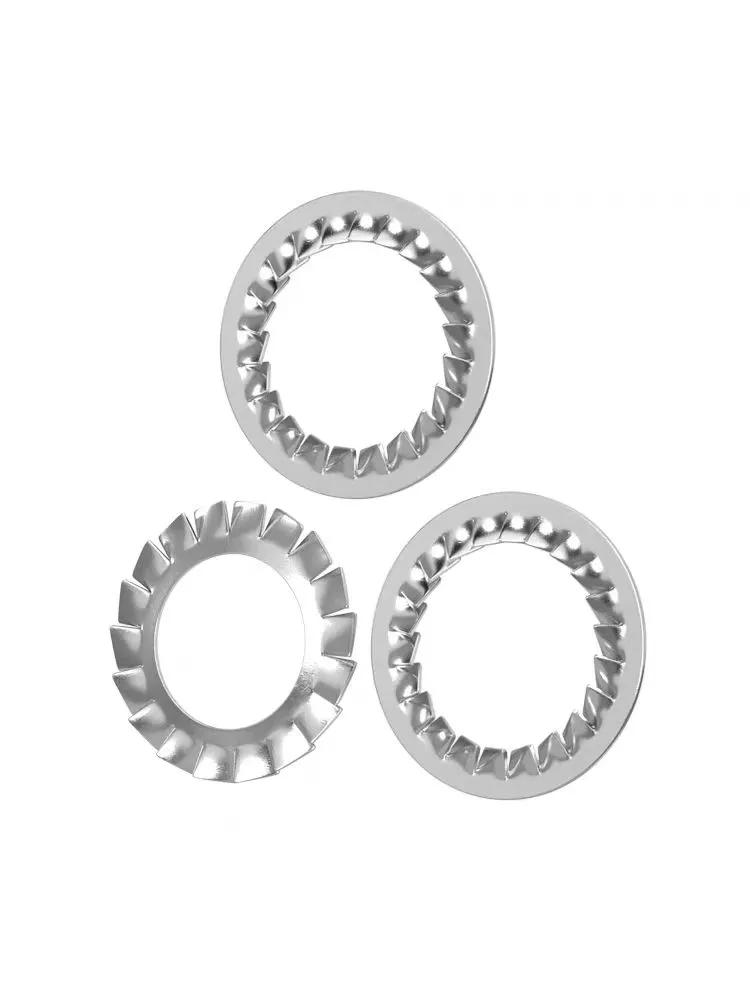

Flange nuts, often referred to as flanged nuts, are an essential component in various mechanical applications. Among the various sizes available, the 4mm flange nut holds particular significance due to its compact design and versatile usability. This article explores the characteristics, benefits, and common applications of the 4mm flange nut.

What is a 4mm Flange Nut?

A flange nut is a type of nut that features an integrated flange at its base. This design increases the surface area that is in contact with the workpiece, effectively distributing the load and reducing the risk of damage to delicate materials. The 4mm flange nut, in particular, has a nominal diameter of 4mm, which makes it suitable for small-scale applications where space is at a premium.

Key Characteristics

1. Material Composition Typically, flange nuts are made from materials such as steel, stainless steel, or plastic, depending on the intended application. Steel offers high strength and durability, while stainless steel is preferred for its corrosion resistance. Plastic flange nuts are used in electronic applications where metal components may cause interference.

2. Load Distribution The flange design allows for better load distribution compared to regular nuts. This feature minimizes the chances of loosening under vibration and enhances the overall stability of the assembly.

3. Ease of Installation The larger contact area of the flange allows for easier installation, especially in tight spaces. Users can often hand-tighten these nuts more effectively without the need for additional tools in some configurations.

4. Versatility The 4mm size fits many small bolts and screws, making these nuts adaptable for various applications, from automotive to electronics, hobby projects, and more.

Advantages of 4mm Flange Nuts

1. Enhanced Grip The flange provides a better grip on the surface, which prevents slippage and ensures a secure connection. This is particularly important in environments subject to vibrations.

4mm flange nut

2. Reduced Risk of Damage By spreading the load across a larger area, 4mm flange nuts help reduce the risk of damaging the surface of the material being fastened. This is especially beneficial when working with softer materials such as plastic or aluminum.

3. Aesthetically Pleasing The flange nut’s design can also add to the overall aesthetics of the project, providing a neat finish that is visually appealing.

Common Applications

1. Electronics In the world of electronics, 4mm flange nuts are often used to secure circuit boards and other components within enclosures. The lightweight nature and the reduced risk of damage to electronic parts make them an excellent choice.

2. Automotive Industry These nuts are frequently used in the assembly of smaller components such as engine parts, trim panels, and interior fittings. The ability to withstand high levels of vibration makes them suitable for automotive applications.

3. DIY Projects and Models Hobbyists and DIYers often engage with 4mm flange nuts in model building, robotics, and other creative projects. Their size and versatility make them perfect for a range of small home projects.

4. Furniture Manufacturing In assembling flat-pack furniture, 4mm flange nuts are sometimes used to provide a secure fit, allowing for easy assembly and disassembly.

5. Optical Devices In precise applications such as optical devices, where alignment is crucial, these nuts help maintain structural integrity without interfering with optical lines.

Conclusion

The 4mm flange nut is a small but mighty component that plays an indispensable role in various industries. Its unique design offers enhanced load distribution, ease of installation, and versatility, making it a popular choice for engineers, manufacturers, and hobbyists alike. Whether you are working on a detailed electronic project or assembling a piece of furniture, understanding the functionality and application of 4mm flange nuts can significantly contribute to the success of your endeavor. Their combination of strength and precision illustrates how even the smallest components can have a profound impact in engineering and everyday applications.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025