3 8 24 Flange Lock Nut Specifications and Features for Industrial Applications

Oct . 13, 2024 00:36 Back to list

3 8 24 Flange Lock Nut Specifications and Features for Industrial Applications

Understanding the 3% 208% 2024 Flange Lock Nut

In the realm of mechanical engineering and fastening technology, the significance of durable and reliable fastening components cannot be overstated. Among the plethora of available options, the 3% 208% 2024 flange lock nut stands out as an exemplary choice, especially when it comes to applications requiring enhanced locking mechanisms and structural integrity. This article delves into the features, benefits, and applications of this specific type of lock nut.

What is a Flange Lock Nut?

A flange lock nut, often referred to as a flanged nut, is distinct from traditional nuts due to its integrated flange. This flange serves two fundamental purposes it provides a larger bearing surface which can help distribute the load across a wider area, reducing the potential for damage or deformation of the materials being bolted together, and it also acts as a self-locking mechanism, preventing the nut from loosening due to vibrations.

The 3% 208% 2024 specification is crucial in understanding the exact composition and properties of the lock nut. Generally, the numbers hint at specific material compositions and mechanical properties, signifying a particular alloy designation or strength classification.

Material Composition and Strength

The designation 2024 typically refers to a specific aluminum alloy that is known for its high strength, excellent fatigue resistance, and good machinability. The 3% and 208% components could refer to particular enhancements or treatments that improve the properties of the basic aluminum alloy. For instance, certain percentages of copper or other alloying elements can significantly bolster strength and durability, making these nuts suitable for high-stress applications.

2024 aluminum alloy is often used in aerospace engineering due to its lightweight yet robust nature. Flange lock nuts made from this material can resist thermal expansion and maintain their structural integrity even under extreme operational conditions.

Advantages of Using 3% 208% 2024 Flange Lock Nuts

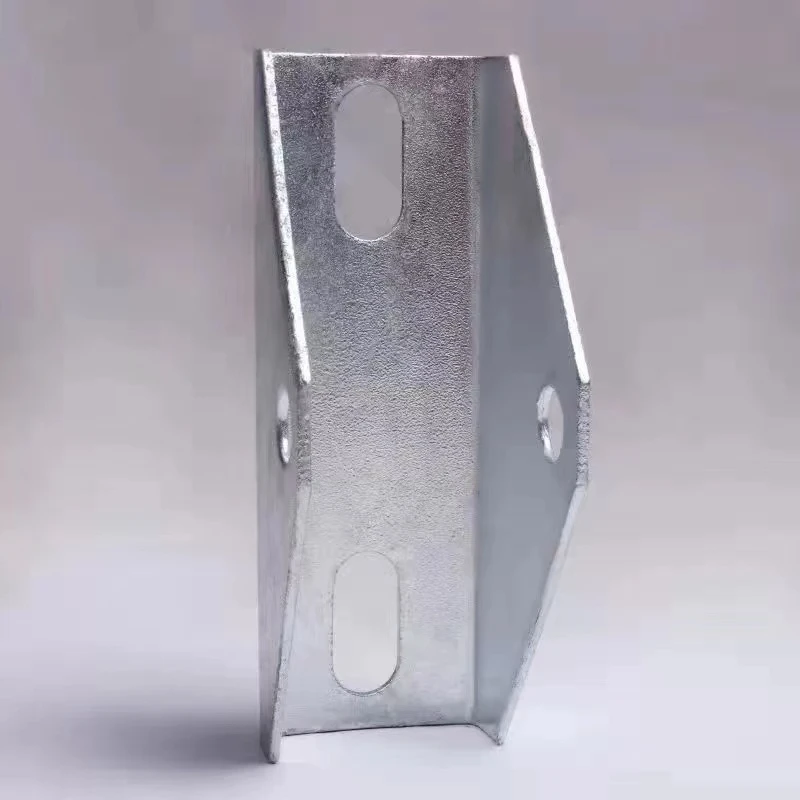

3 8 24 flange lock nut

1. High Strength-to-Weight Ratio The incorporation of 2024 aluminum ensures that the flange lock nuts are lightweight while still providing high tensile strength. This is particularly beneficial in industries where weight reduction is critical, such as aerospace and automotive.

2. Vibration Resistance The flange design coupled with the locking mechanism makes these nuts resistant to loosening under vibrational forces, which is essential for maintaining the reliability and safety of mechanical assemblies.

3. Ease of Installation The integrated flange not only simplifies installation but also minimizes the risk of damage to mating surfaces during tightening. This can lead to reductions in assembly times and costs.

4. Corrosion Resistance Aluminum alloys typically offer moderate corrosion resistance, making these nuts suitable for applications in various environmental conditions.

5. Wide Applications These flange lock nuts are versatile and can be utilized in numerous industries, including aerospace, automotive, construction, and general engineering.

Applications

The 3% 208% 2024 flange lock nuts find their use in multiple applications. In aerospace, they may be employed in aircraft assembly where weight and strength are critical. In automotive engineering, they could be part of engine assemblies or suspension systems, where reliability is paramount. Additionally, these nuts can be found in structural applications, machinery, and even consumer products where robust fastening solutions are necessary.

Conclusion

In conclusion, the 3% 208% 2024 flange lock nut exemplifies a perfect fusion of design and material science aimed at providing advanced fastening solutions. Its benefits, including high strength, vibration resistance, and ease of installation, make it an invaluable component across various industries. As engineers continue to push the boundaries of technology, the demand for innovative fastening solutions like the flange lock nut will undoubtedly grow, paving the way for more efficient and secure mechanical designs.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025