3 4 inch flange nut

Jan . 19, 2025 23:57 Back to list

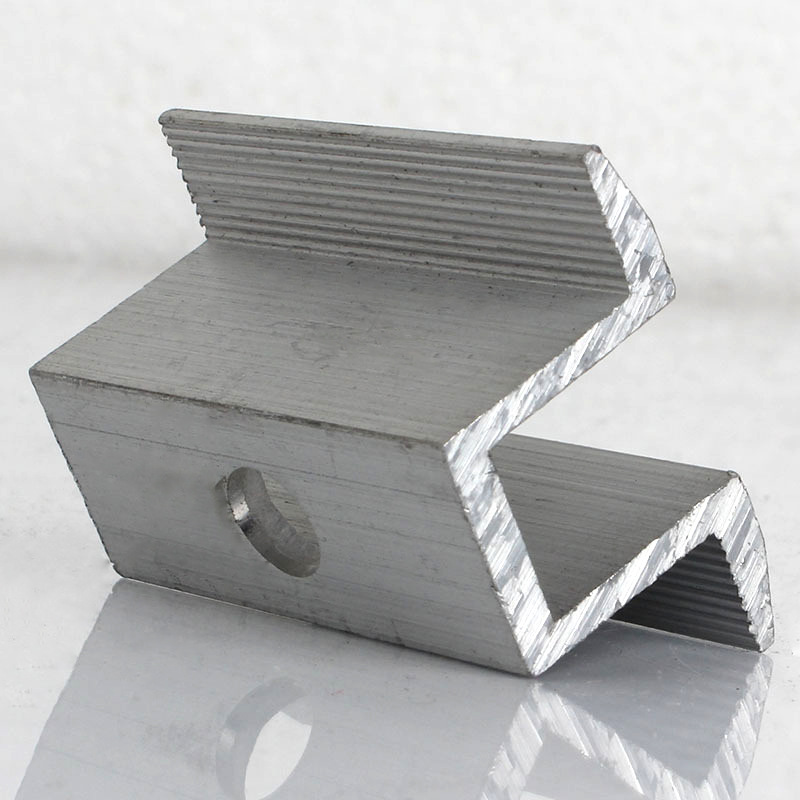

3 4 inch flange nut

The 3/4 inch flange nut is an engineered marvel of versatility and precision, playing an indispensable role in various mechanical and industrial applications. This nut, characterized by its unique design and dimensions, is a powerhouse of functionality, and deep diving into its specifics reveals a blend of reliability and innovation which every industry professional should be acquainted with.

Authors and engineers in power plant sectors also underscore the importance of using 3/4 inch flange nuts on maintenance-critical equipment. The reliability these nuts offer in high-pressure scenarios stands out, making them a preferred choice in ensuring fluid-sealed connections. Authoritative publications have recognized the flange nut’s superior ability to maintain strong connections under both rapid temperature fluctuations and constant pressure changes. Trust in these components is not built solely on technical specifications but on historical performance. Long-term users, including certified mechanics and industrial engineers, often recount instances where these nuts have outperformed standard washers, delivering consistent results during regular operational checks and unexpected performance peaks. As we embrace evolving industry trends leaning towards automation and improved safety standards, flange nuts continue to gain traction. They align with the goals of manufacturers who aim to reduce human error in assembling processes and enhance the efficiency of automated production lines. The 3/4 inch flange nut, with its self-locking capability, represents a step forward in meeting these safety benchmarks. Thus, any organization or workshop looking to elevate their bolting toolset’s reliability and efficacy should consider integrating 3/4 inch flange nuts. Their proven track record, combined with ongoing advancements in material science, makes them a staple choice and an intelligent investment for forward-thinking projects. This is a component that not only supports today’s needs but is well-poised to meet future demands, making it an essential addition to any comprehensive engineering toolkit.

Authors and engineers in power plant sectors also underscore the importance of using 3/4 inch flange nuts on maintenance-critical equipment. The reliability these nuts offer in high-pressure scenarios stands out, making them a preferred choice in ensuring fluid-sealed connections. Authoritative publications have recognized the flange nut’s superior ability to maintain strong connections under both rapid temperature fluctuations and constant pressure changes. Trust in these components is not built solely on technical specifications but on historical performance. Long-term users, including certified mechanics and industrial engineers, often recount instances where these nuts have outperformed standard washers, delivering consistent results during regular operational checks and unexpected performance peaks. As we embrace evolving industry trends leaning towards automation and improved safety standards, flange nuts continue to gain traction. They align with the goals of manufacturers who aim to reduce human error in assembling processes and enhance the efficiency of automated production lines. The 3/4 inch flange nut, with its self-locking capability, represents a step forward in meeting these safety benchmarks. Thus, any organization or workshop looking to elevate their bolting toolset’s reliability and efficacy should consider integrating 3/4 inch flange nuts. Their proven track record, combined with ongoing advancements in material science, makes them a staple choice and an intelligent investment for forward-thinking projects. This is a component that not only supports today’s needs but is well-poised to meet future demands, making it an essential addition to any comprehensive engineering toolkit.

Next:

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025