3 8 16 flange lock nut

Aug . 31, 2024 11:43 Back to list

3 8 16 flange lock nut

Understanding the 3 8 16 Flange Lock Nut A Comprehensive Overview

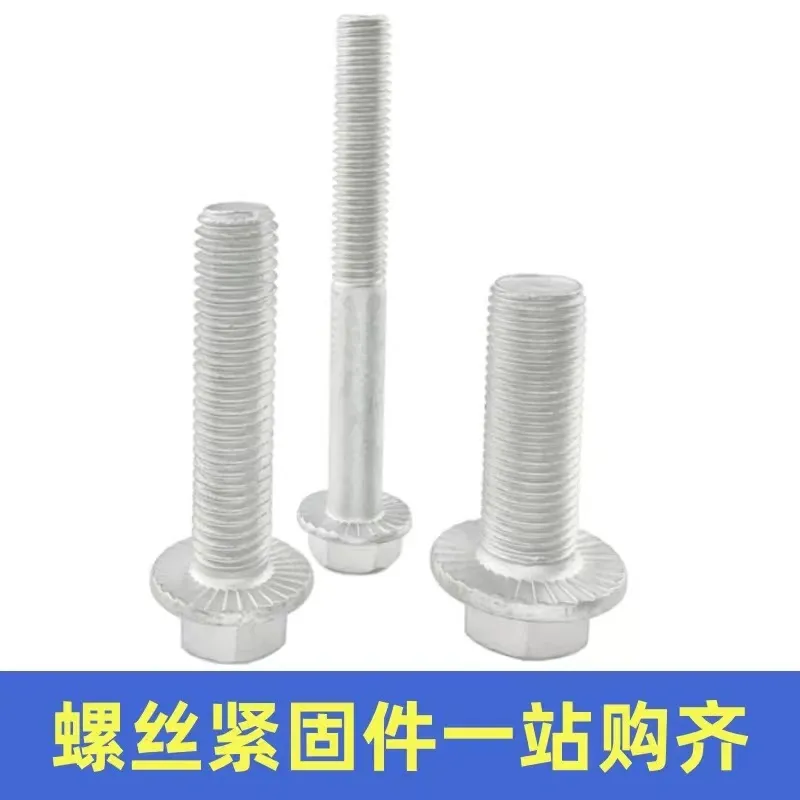

In the world of fasteners, few components are as essential and widely used as nuts and bolts. Among these, the flange lock nut has gained significant traction due to its unique design and inherent advantages. This article delves into the specifics of the 3 8 16 flange lock nut, exploring its functionality, applications, and benefits.

What is a Flange Lock Nut?

A flange lock nut is a type of nut that features a circular flange at its base. This flange acts as a washer, distributing the load more evenly and providing a larger bearing surface than traditional nuts. The increased surface area helps to minimize the chances of loosening due to vibrations or other dynamic forces. Lock nuts, in general, are designed to resist rotation and maintain torque levels, making them ideal for applications where stability is critical.

The 3 8 16 Specification

The designation 3 8 16 typically relates to the specifications set forth by various engineering and manufacturing standards. The numerical values may signify dimensions, material grades, or specific qualities required for different applications. Understanding these parameters is crucial for engineers and technicians when selecting the right fastener for their projects.

In practical terms, the 3 might indicate a size or thread pitch; 208 could represent a specific material standard, while 2016 often pertains to the year of specification or a particular industry standard. It's vital to consult the relevant standards or a materials engineer to fully grasp the implications of these numbers and their importance in engineering applications.

Key Applications

Flange lock nuts are widely utilized across various industries, including automotive, aerospace, manufacturing, and construction. Their robust design makes them suitable for high-stress environments where vibration and movement could otherwise lead to loosening fasteners. Common applications include

- Automotive Assemblies Flange lock nuts are favored in vehicle assemblies where safety and reliability are paramount. They are used to secure components such as exhaust systems, suspension parts, and drivetrain assemblies.

3 8 16 flange lock nut

- Aerospace In aviation, the importance of securing components cannot be overstated. Flange lock nuts provide the necessary reliability in high-vibration environments like aircraft engines and fuselage assemblies.

- Construction Machinery Heavy machinery relies on durable fasteners to withstand significant forces. Flange lock nuts help ensure that bolts do not loosen over time, which can be critical for the safety of equipment operators.

Benefits of Using Flange Lock Nuts

1. Increased Security The design of flange lock nuts reduces the risk of loosening, providing a more secure fastening method compared to standard nuts.

2. Vibration Resistance These nuts excel in applications prone to vibrations, ensuring longer service life for the assembled components.

3. Load Distribution The flange distributes the load, minimizing stress concentration and wear on the assembly.

4. Ease of Installation Flange lock nuts are typically easier to install and remove than standard lock nuts, as they do not require additional washers or retaining devices.

Conclusion

The 3 8 16 flange lock nut is a crucial component in various engineering and construction applications. With its unique benefits of enhanced security, resistance to vibrations, and load distribution capabilities, it remains a preferred choice for professionals in multiple industries. Understanding its specifications and applications is essential for engineers and technicians aiming to create secure and reliable assemblies.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025