12mm flange nut

Oct . 17, 2024 00:54 Back to list

12mm flange nut

Understanding the Importance of 12mm Flange Nuts

In the world of engineering and construction, fasteners play a crucial role in ensuring structural integrity and reliability. Among these fasteners, the 12mm flange nut has gained significant attention due to its distinctive design and versatile applications. This article explores the characteristics, applications, and advantages of using 12mm flange nuts.

What is a Flange Nut?

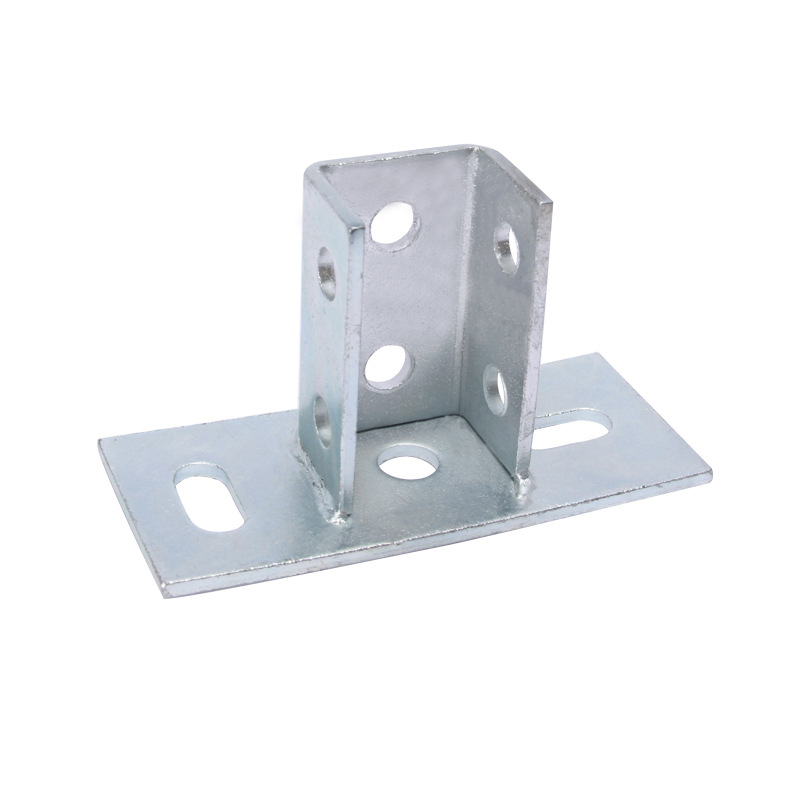

A flange nut can be identified by its integral flange – a broad, protruding edge at one end. This mechanism allows the flange nut to distribute the load over a larger surface area, which reduces the chances of damage to the material being fastened. Typically, flange nuts come with a hexagonal shape that allows for easy tightening with standard tools. The 12mm designation refers to the width of the nut, indicating that it is suitable for use with a 12mm bolt.

Key Characteristics

- Load Distribution The flange serves to spread the load, providing enhanced holding power compared to regular nuts. This is particularly important in applications where vibration could loosen standard nuts. - Integrated Washer Effect The flange acts as a built-in washer, which can prevent the nut from loosening over time and protect the underlying surface from damage.

- Material Versatility Flange nuts can be made from various materials, including steel, stainless steel, and plastic, making them suitable for different environments and applications. Stainless steel flange nuts, for instance, are excellent for outdoor or marine applications due to their corrosion resistance.

- Variety of Finishes These nuts can also be found in various finishes, including zinc plating, which further enhances their durability and resistance to environmental factors.

Applications of 12mm Flange Nuts

The 12mm flange nut is widely used in several industries due to its robust design and reliability. Common applications include

12mm flange nut

- Automotive Industry In automotive assembly, flange nuts are often used to secure components where vibration is a concern. Their ability to stay in place under dynamic conditions makes them preferable in vehicle manufacturing.

- Construction In construction projects, flange nuts are commonly used in connection bolts for structural integrity. The load distribution offered by the flange is particularly beneficial when securing beams and columns.

- Machinery and Equipment Many machines employ flange nuts to hold parts together. The reduced chance of loosening leads to enhanced operational stability, which is vital for machine performance.

Advantages of Using 12mm Flange Nuts

1. Reduced Risk of Loosening The design of flange nuts minimizes the possibility of unintentional loosening, which is essential in high-vibration environments.

2. Ease of Installation Flange nuts typically require less effort to install compared to standard nuts, streamlining the assembly process.

3. Versatile Use The 12mm size is compatible with a range of bolts, making these nuts a versatile choice for various applications, whether in construction, automotive, or machinery.

4. Cost-Effectiveness By providing stability and reducing the need for additional components, flange nuts can contribute to cost savings in assembly and maintenance.

In conclusion, the 12mm flange nut is a reliable and efficient fastener that is essential in modern industry and construction. Its design offers numerous advantages that enhance performance and durability, making it a preferred choice for professionals across various fields. Understanding its applications and benefits can lead to better decision-making when selecting fasteners for specific projects.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025