1 2 13 flange nut

Jan . 14, 2025 11:19 Back to list

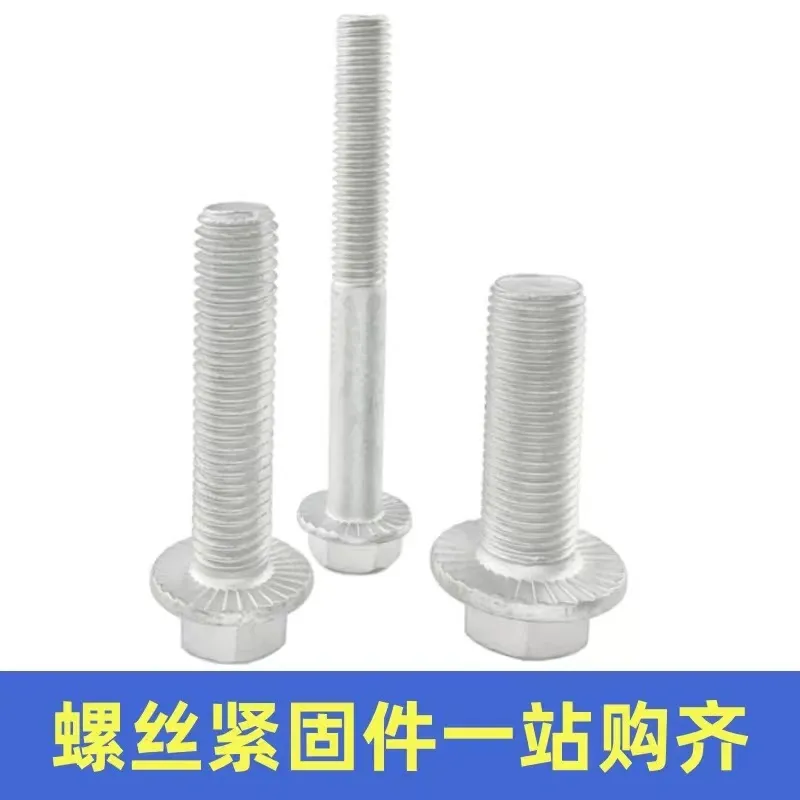

1 2 13 flange nut

Unveiling the Superior Mechanics Behind the 1 2 13 Flange Nut

The expertise behind the engineering of the 1 2 13 flange nut is reflected in its application across various industries. In the automotive sector, it is a preferred choice for securing components without the risk of back-off due to mechanical vibrations. Construction professionals also appreciate its ability to maintain structural integrity even in high-stress scenarios, such as when reinforcing beams or securing heavy-duty equipment. Meanwhile, in the realm of home improvement, DIY enthusiasts and skilled tradespeople alike utilize this component for projects ranging from furniture assembly to intricate machinery repairs. Trust in the 1 2 13 flange nut is not unfounded; it is borne out of years of proven use in challenging scenarios. As manufacturing techniques evolve, flange nuts continue to be rigorously tested to meet stringent quality standards. Certifications from international bodies such as ISO often accompany these components, providing assurance of their high-grade construction and reliability. Real-world experiences further affirm the remarkable capabilities of the 1 2 13 flange nut. Technicians and engineers have attested to its superior performance in scenarios demanding high resistance to wear and tear. For instance, in the maintenance of heavy industrial equipment, the use of flange nuts has been a game-changer, reducing downtime by maintaining secure joint tension over extended periods. In summary, the 1 2 13 flange nut is more than just a component; it is a testament to the evolution of engineering and design precision. Its integration into projects signifies a commitment to quality, reliability, and efficient engineering solutions. Whether it's the versatility across different applications, the peace of mind it provides through its robust construction, or its ability to withstand the pulse of industrial demands, the 1 2 13 flange nut stands as a pillar of mechanical innovation, an indispensable asset in the world of complex assemblies.

The expertise behind the engineering of the 1 2 13 flange nut is reflected in its application across various industries. In the automotive sector, it is a preferred choice for securing components without the risk of back-off due to mechanical vibrations. Construction professionals also appreciate its ability to maintain structural integrity even in high-stress scenarios, such as when reinforcing beams or securing heavy-duty equipment. Meanwhile, in the realm of home improvement, DIY enthusiasts and skilled tradespeople alike utilize this component for projects ranging from furniture assembly to intricate machinery repairs. Trust in the 1 2 13 flange nut is not unfounded; it is borne out of years of proven use in challenging scenarios. As manufacturing techniques evolve, flange nuts continue to be rigorously tested to meet stringent quality standards. Certifications from international bodies such as ISO often accompany these components, providing assurance of their high-grade construction and reliability. Real-world experiences further affirm the remarkable capabilities of the 1 2 13 flange nut. Technicians and engineers have attested to its superior performance in scenarios demanding high resistance to wear and tear. For instance, in the maintenance of heavy industrial equipment, the use of flange nuts has been a game-changer, reducing downtime by maintaining secure joint tension over extended periods. In summary, the 1 2 13 flange nut is more than just a component; it is a testament to the evolution of engineering and design precision. Its integration into projects signifies a commitment to quality, reliability, and efficient engineering solutions. Whether it's the versatility across different applications, the peace of mind it provides through its robust construction, or its ability to withstand the pulse of industrial demands, the 1 2 13 flange nut stands as a pillar of mechanical innovation, an indispensable asset in the world of complex assemblies.

Next:

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025