non serrated flange nuts

Okt . 02, 2024 16:59 Back to list

non serrated flange nuts

Understanding Non-Serrated Flange Nuts Features and Applications

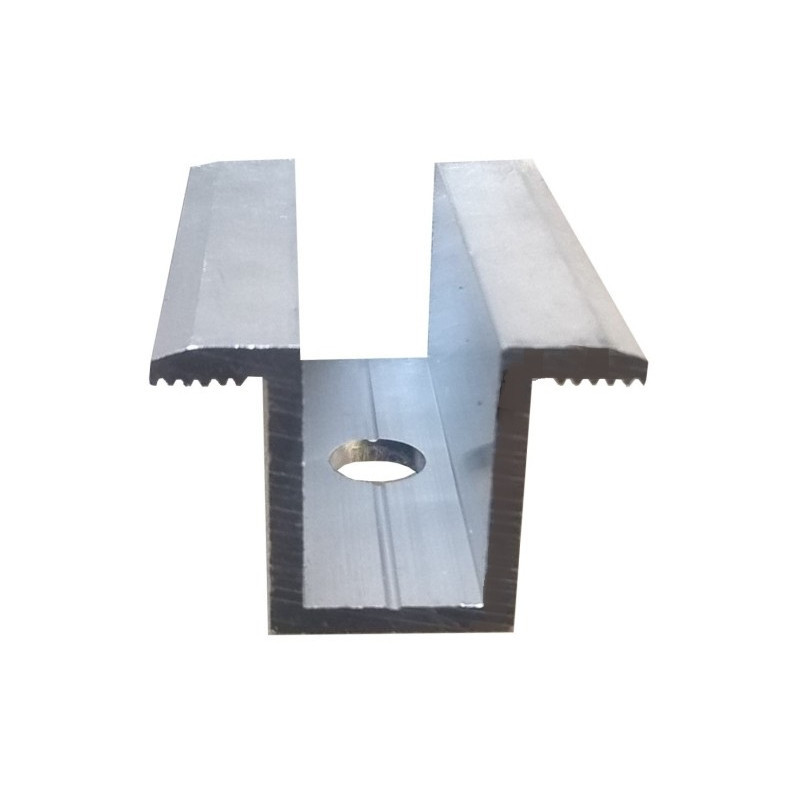

Non-serrated flange nuts are a specific type of fastener that has gained popularity across various industries due to their unique design and functional benefits. These nuts are characterized by a broad, flat flange that distributes the load over a larger area, reducing the risk of damage to the materials being fastened. Unlike serrated flange nuts, which have teeth or serrations to enhance grip, non-serrated flange nuts rely solely on the flat surface to secure the bolted connection.

Understanding Non-Serrated Flange Nuts Features and Applications

Although non-serrated flange nuts may not provide the same grip as their serrated counterparts, they are often preferred in situations where aesthetic considerations are essential. The smooth surface of non-serrated flange nuts can be more visually appealing, making them suitable for applications where visibility is a factor, such as in exposed structures or machinery.

non serrated flange nuts

Non-serrated flange nuts are versatile and compatible with various bolt types. They are often made from materials such as steel, stainless steel, or alloy to cater to different environmental conditions, including high temperatures and corrosive settings. The choice of material greatly affects the performance and durability of the nuts, so careful consideration should be given to the specific requirements of each application.

Applications for non-serrated flange nuts are abundant. They are commonly found in automotive assemblies, construction projects, and machinery manufacturing. Their ability to maintain tight connections without damaging the workpiece makes them a preferred choice in industries where reliability and strength are paramount.

In conclusion, non-serrated flange nuts serve as a crucial component in many mechanical systems. With their unique design that promotes load distribution and stability, they are an excellent choice for various applications that demand high performance without compromising aesthetics. As technology advances, the ongoing development and refinement of these fasteners continue to enhance their utility and applicability across multiple industries.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025