Understanding ASTM A325 Structural Bolts for Enhanced Construction Reliability and Performance

Nov . 18, 2024 08:38 Back to list

Understanding ASTM A325 Structural Bolts for Enhanced Construction Reliability and Performance

Understanding ASTM A325 Structural Bolts

ASTM A325 is a standard specification released by the American Society for Testing and Materials (ASTM) that outlines the requirements for high-strength steel bolts used in structural steel connections. Specifically designed for use in bolted structural assemblies, A325 bolts are vital in ensuring the integrity and stability of buildings, bridges, and other structures subjected to dynamic loads and environmental stresses.

Composition and Types

ASTM A325 bolts are made from medium carbon steel that is quenched and tempered, yielding a high-strength product capable of enduring significant tensile and shear forces. The specification defines two types of A325 bolts Type 1, which is made from a carbon steel alloy, and Type 2, which is made from a weathering steel with enhanced corrosion resistance. The difference in material composition directly influences the bolt's performance, making it essential to select the appropriate type for specific environmental conditions.

Size and Dimensions

A325 bolts come in various sizes, typically ranging from 1/2 inch to 1-1/2 inches in diameter. The length of the bolts can vary based on the application requirements, allowing engineers to choose dimensions that best fit the structural needs of their projects. The standard also specifies thread dimensions, ensuring compatibility with nuts and washers used in conjunction with these bolts.

Performance Characteristics

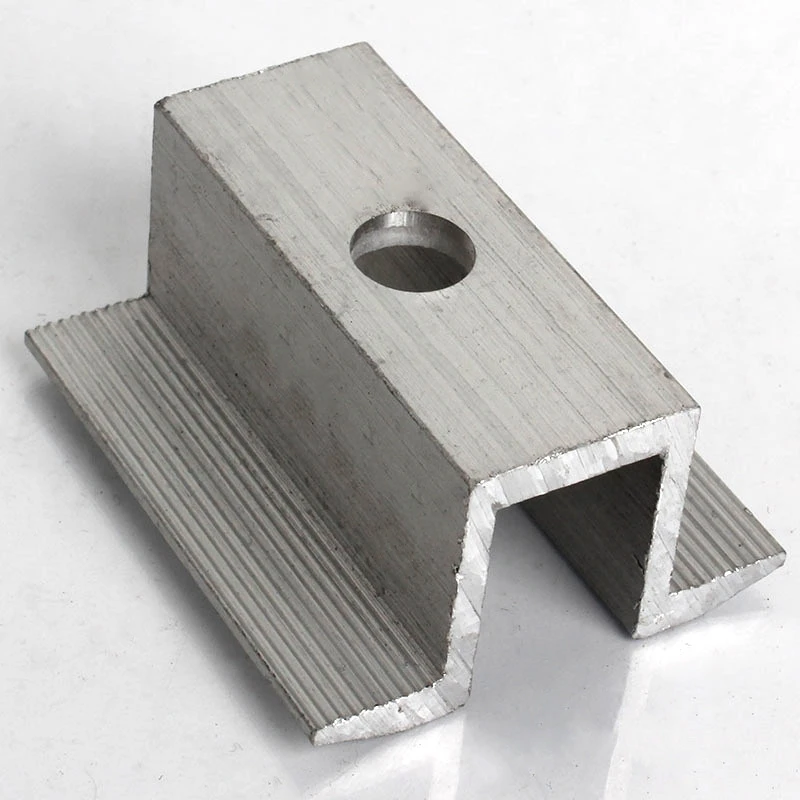

astm a325 structural bolts

One of the key attributes of ASTM A325 bolts is their strength. These bolts have a minimum tensile strength of 120 ksi (kilopounds per square inch), making them suitable for high-strength applications. The standard also outlines the required yield strength, elongation, and hardness, ensuring the bolts perform effectively under stress without failure.

Installation Considerations

Proper installation of A325 bolts is critical for achieving the designed structural performance. The bolts can be tensioned using various methods, including tension control, twist-off, and direct tension indicators. Correct installation ensures that the bolts can accommodate the necessary preload, which helps to resist shear forces and prevents joint separation.

Applications

ASTM A325 bolts are widely used in construction projects, including commercial buildings, bridges, and towers. Their high strength makes them favorable for steel-to-steel connections that need to withstand significant loads, particularly in seismic zones or regions subject to high winds. Construction engineers and architects often rely on A325 bolts for their reliability and proven performance in real-world applications.

Conclusion

In summary, ASTM A325 structural bolts play a crucial role in modern engineering and construction. Their robust design, high strength, and versatility make them an essential component in ensuring safe and reliable structural connections. Understanding their specifications, types, and applications allows engineers to make informed decisions, leading to safer and more resilient infrastructure.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025