Understanding the Impact of Zinc Washers on Rust Resistance and Durability

12월 . 14, 2024 12:32 Back to list

Understanding the Impact of Zinc Washers on Rust Resistance and Durability

Understanding Zinc Washer Rust Causes, Prevention, and Solutions

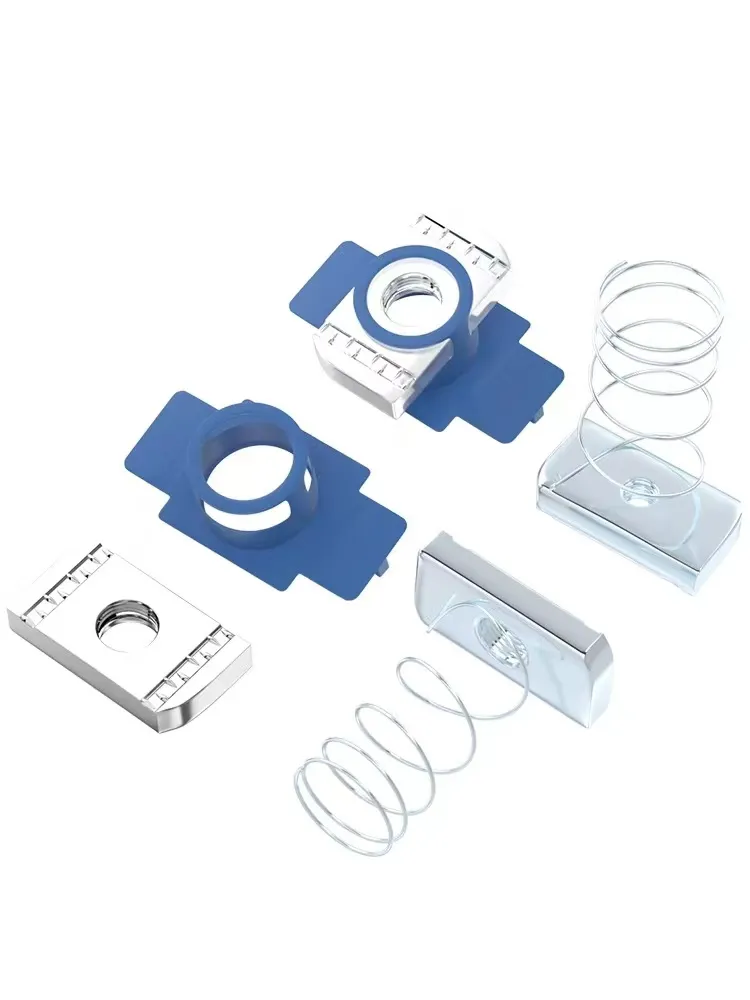

Zinc washers are commonly used in various applications, from construction to automotive industries, due to their excellent corrosion resistance and durability. However, like any metal, zinc can also succumb to rust, leading to potential failures in applications where integrity and reliability are crucial. Understanding why zinc washers rust, how to prevent rust formation, and what solutions exist can help ensure the longevity of these essential components.

Causes of Rust on Zinc Washers

Rust is a term that typically refers to the corrosion of iron, but in the context of zinc washors, it is more accurate to describe the process as zinc corrosion or degradation. Several factors can contribute to this issue

1. Moisture Zinc is more resistant to corrosion than many other metals, but it is not immune. When zinc washers are exposed to moisture, especially in the presence of salts or other corrosive substances, they can begin to corrode. This is particularly true in humid environments or places where water can accumulate.

2. Poor Coating Zinc washers are often coated with a layer of zinc to enhance their resistance to corrosion. However, if the coating is damaged or improperly applied, the base metal may be exposed, increasing the risk of corrosion. Scratches, dents, and dents in the coating can serve as initiation points for rust.

3. Electrolytic Corrosion Zinc is often used in environments where it may come into contact with dissimilar metals. When this occurs, electrolysis can result in accelerated corrosion. This is especially common in applications where zinc washers are used alongside metals such as copper or aluminum, leading to a galvanic reaction.

4. Environmental Factors Certain environmental factors, including high levels of chloride, sulfur, and industrial pollutants, can significantly impact the corrosion resistance of zinc. Coastal areas, for instance, have higher salinity levels, which can speed up the corrosion process.

Preventing Rust on Zinc Washers

To ensure the longevity of zinc washers and prevent rust, several preventive measures can be taken

1. Proper Coating Investing in high-quality zinc-coated washers can provide a more effective barrier against corrosion. When installing, be mindful not to scratch or damage the coating, and choose washers produced through processes like electroplating or hot-dip galvanizing for better protection.

zinc washer rust

2. Reduce Exposure to Moisture In applications where moisture is unavoidable, consider using additional protective measures such as waterproof seals or paints designed for metal surfaces. Ensuring that the washers are not in constant contact with water can also help.

3. Avoid Dissimilar Metals Where possible, avoid pairing zinc washers with dissimilar metals. If it is necessary to use them together, consider using insulating materials or barriers that mitigate electrolysis, as this can significantly extend the lifespan of the washers.

4. Regular Inspections Regularly inspecting zinc washers for signs of corrosion, such as discoloration or pitting, can help detect issues early. Immediate replacement or maintenance can prevent further degradation and potential failures.

Solutions for Rusted Zinc Washers

If you discover that zinc washers have rusted, there are several steps you can take

1. Cleaning and Treatment For light surface corrosion, a gentle cleaning with mild abrasives or rust removal solutions can help restore the washer's surface. After cleaning, consider reapplying a protective coating.

2. Replacement In cases of severe corrosion where the structural integrity of the washer is compromised, replacement is necessary. Inspect other components in the assembly for similar issues to prevent a cascading failure.

3. Use of Alternative Materials If rust proves to be a persistent issue, consider using washers made from stainless steel or other corrosion-resistant alloys that can withstand the specific environmental conditions they are exposed to.

Conclusion

While zinc washers offer excellent corrosion resistance, they are not invincible. By understanding the causes of rust, implementing preventive measures, and knowing how to address corrosion when it occurs, you can extend the life of zinc washers and maintain the integrity of your projects. Regular maintenance and awareness are your best defenses against rust and its consequences in any application.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025