Understanding the Importance of Metric Bolts in Engineering Applications and Standards

12월 . 26, 2024 02:09 Back to list

Understanding the Importance of Metric Bolts in Engineering Applications and Standards

Understanding Metric Bolts A Comprehensive Guide

In the realm of engineering and construction, proper fasteners are crucial to ensuring structural integrity and reliability. Among the various fasteners used, bolts hold a particularly prominent place. Specifically, metric bolts have become increasingly popular in global applications due to their consistency, measurement standards, and efficiency. This article delves into the intricacies of metric bolts, exploring their specifications, uses, and advantages.

What are Metric Bolts?

Metric bolts are specialized fasteners that conform to the metric system of measurement. Unlike their imperial counterparts, which are measured in inches, metric bolts are measured in millimeters (mm). This distinction plays a vital role in international trade, allowing for easier collaboration and standardization across different countries and industries. Common ranges for metric bolt diameters include M3, M4, M5, up to larger sizes like M30 or M36, signifying their major diameter in millimeters.

Classification of Metric Bolts

Metric bolts can be classified based on several criteria, including their head type, thread type, and strength grades. The most common head types include hexagonal, square, and round heads, while thread types can be coarse or fine. The strength of metric bolts is classified using the ISO metric system, which categorizes them into various grades such as 8.8, 10.9, and 12.9, indicating tensile strength and yield strength. For instance, a grade 8.8 bolt has a tensile strength of 800 MPa, making it suitable for a range of applications.

Applications of Metric Bolts

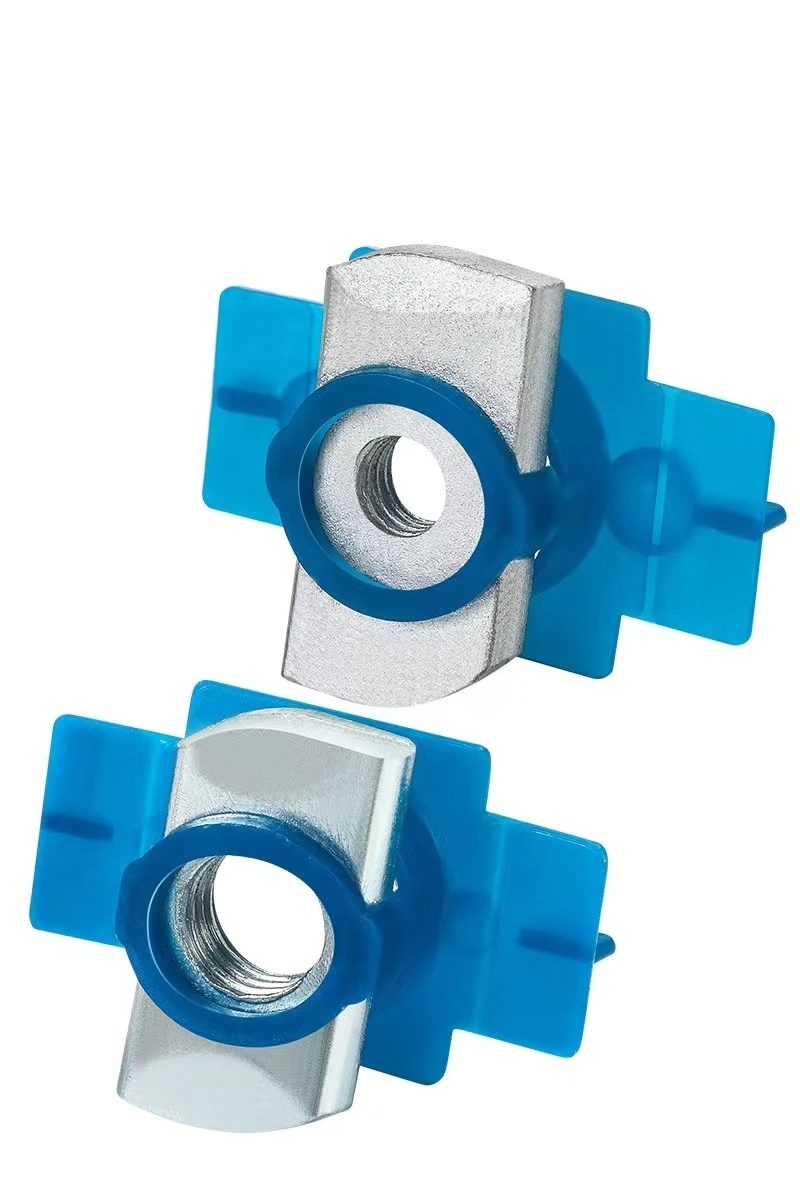

metric bolts

Metric bolts are widely used in various industries, including automotive, aerospace, construction, and machinery manufacturing. Their standardized nature makes them suitable for assembly lines and mass production, leading to lower variability and higher efficiency. In the automotive industry, metric bolts are essential for securing engine components and chassis parts. In construction, they are used to connect structural elements like beams and columns, providing stability to buildings and bridges.

Advantages of Using Metric Bolts

One of the primary advantages of metric bolts is their consistency and precision. Since they adhere to international standards set by the International Organization for Standardization (ISO), engineers and manufacturers can rely on the dimensions, tolerances, and strength markings of metric bolts. This uniformity minimizes the risk of mismatched components, leading to smoother assembly processes.

Additionally, the availability of metric bolts in various materials and coatings enhances their versatility. Common materials include carbon steel, stainless steel, and alloy steel, each offering different properties such as corrosion resistance and tensile strength. Options for coatings, such as zinc plating and black oxide, further improve their durability and performance in specific environments.

Another noteworthy benefit is the ease of interchangeability. With so many countries adopting the metric system, it is simple for manufacturers to source components globally, reducing lead times and costs associated with production. It also encourages innovation, as engineers can readily incorporate new technologies and materials into their designs without worrying about compatibility issues.

Conclusion

The importance of metric bolts in modern engineering cannot be overstated. As industries continue to globalize and embrace standardization, the reliance on metric fasteners will only increase. Understanding the specifications, applications, and advantages of metric bolts empowers engineers and manufacturers to choose the right fasteners for their projects. Whether it’s building a high-rise building, assembling an aircraft, or manufacturing precision machinery, the right metric bolt can make all the difference in ensuring safety, functionality, and longevity in designs. As we move forward, the metric bolt will remain a cornerstone in the world of fasteners, and its relevance will continue to thrive in diverse fields.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025