Understanding the Importance of Hexagonal Nuts in Mechanical Engineering Applications

11월 . 09, 2024 15:14 Back to list

Understanding the Importance of Hexagonal Nuts in Mechanical Engineering Applications

The Hexagonal Nut A Versatile Fastening Solution

In the vast world of mechanical engineering and construction, fastening components securely together is essential for ensuring the safety and reliability of structures and machines. One of the most ubiquitous yet often overlooked components in this realm is the hexagonal nut. This simple yet profoundly effective component plays a critical role in the assembly of various machinery, automotive applications, and structural frameworks.

Design and Features

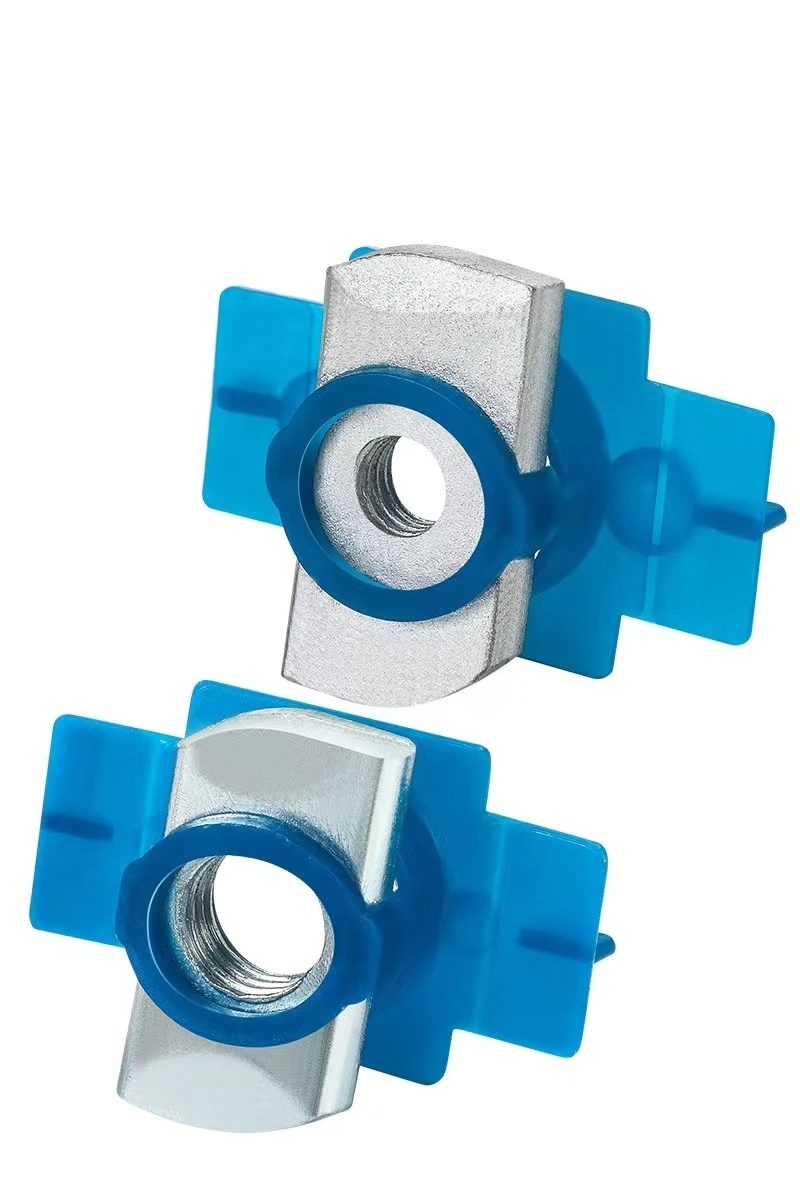

The hexagonal nut is characterized by its six-sided shape, which allows for easy grip and application of torque with a standard wrench or socket. Generally made from materials like steel, stainless steel, bronze, or plastic, these nuts boast a range of properties that enhance their performance. For example, high-strength steel nuts can withstand significant tensile loads, making them ideal for heavy-duty applications.

Hexagonal nuts come in various grades and specifications, each tailored to specific applications. The grade refers to the material's strength and quality, while specifications often account for dimensions, thread type, and coating. The versatility in design allows engineers to select the optimal type based on the requirements of the project at hand, whether it involves high temperatures, corrosion resistance, or simply the need for lightweight materials.

Applications Across Industries

The applications of hexagonal nuts are as diverse as the industries in which they are used

. In the automotive sector, they are crucial for securing engine components and assemblies, ensuring that parts remain firmly fastened during operation. In construction, hexagonal nuts are essential in securing steel beams, bridges, and other infrastructure elements, contributing to the stability and safety of the overall structure.The aerospace industry also utilizes hexagonal nuts extensively. Given the high-stress conditions that aircraft undergo, using high-strength hexagonal nuts is vital. Aviation-grade nuts are designed to meet stringent safety standards and can operate effectively at extreme altitudes and temperatures. Furthermore, in electronics, smaller hexagonal nuts assist in securing circuit boards and other critical components.

hexagonal nut

Advantages

The hexagonal shape of these nuts provides several advantages. Primarily, their six sides offer a larger surface area for torque application, reducing the chances of slippage compared to other shapes like square nuts. This characteristic allows for a tighter and more secure fastening, which is paramount in high-stress environments. The ease of installation and removal is another considerable benefit; a standard wrench can grip multiple faces, making it easier to achieve the necessary torque without requiring specialized tools.

Aside from functionality, hexagonal nuts are cost-effective. The manufacturing processes involved in producing these nuts are well-established, allowing for mass production without significantly driving up costs. This economic advantage, combined with their reliability, makes them a staple in both industrial and DIY projects.

Limitations and Considerations

Despite their numerous advantages, hexagonal nuts are not without limitations. One primary concern is the potential for loosening over time due to vibrations—a common issue in machinery and automotive applications. Various solutions, such as lock nuts, nylon inserts, and threadlocking adhesives, are available to address this challenge. Furthermore, the protrusion of hexagonal nuts can pose a snagging hazard in certain applications, prompting engineers to consider alternative fastening solutions when space is limited.

Additionally, the necessity for a compatible bolt with matching thread specifications is crucial. Using a nut and bolt with incompatible threads can lead to structural failure, so attention to detail in selection and installation is vital.

Conclusion

In summary, the hexagonal nut is a fundamental component that plays a crucial role in various applications. Its simple design belies its versatility and strength, making it an indispensable element in fastening technology. Whether in aerospace, automotive, construction, or electronics, hexagonal nuts provide the reliability and ease of use needed to assemble complex systems securely. As engineering challenges continue to evolve, so too will the designs and applications of hexagonal nuts, ensuring their place in the future of fastening solutions.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025