flat washers

1월 . 31, 2025 05:10 Back to list

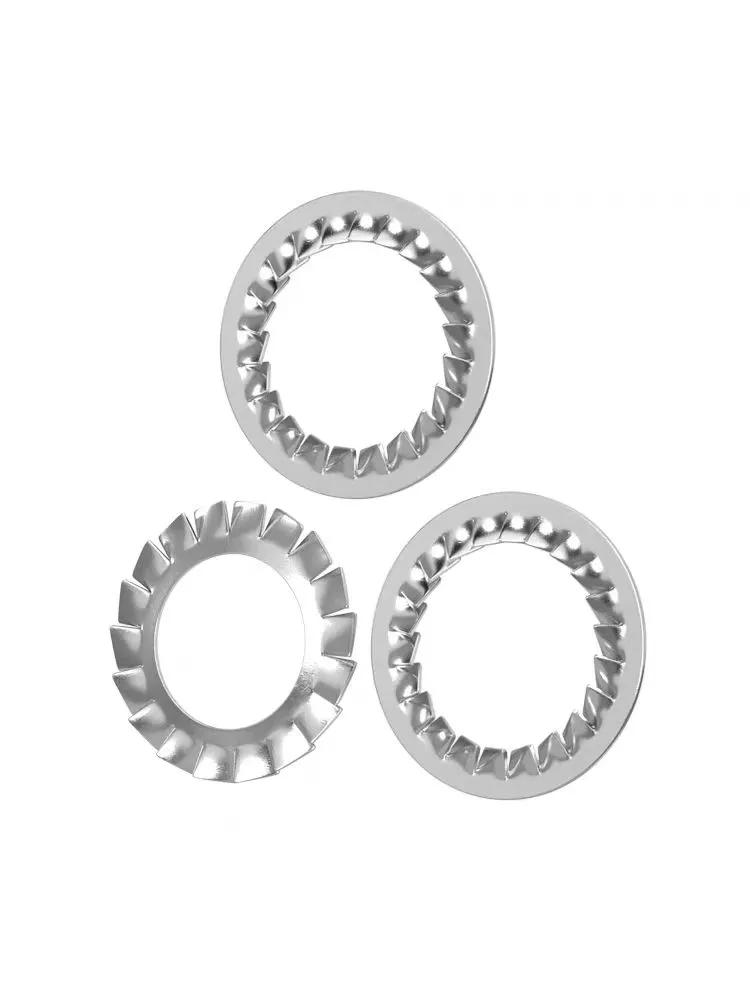

flat washers

Flat washers, often overlooked yet fundamental components in numerous construction and repair projects, serve as indispensable tools across various industries. Their function, design, and application require an understanding grounded in both expertise and practical insights.

In a more technological environment, such as the assembly of electrical panels, flat washers support not just structural stability but also address conductivity and insulation needs. Brass washers, for example, might be chosen for their superior electrical conductivity, while nylon washers would serve in non-conductive roles, preventing shorts and ensuring the safety and efficiency of the electrical system. The authoritative role flat washers play in engineering applications extends beyond their mere physical presence. They embody precision engineering principles, reflecting improvements in manufacturing techniques and material sciences. This alignment with advanced engineering validates their indispensable nature in construction and design projects. The trust bestowed upon these components is measurable by their ubiquitous presence in various applications, from everyday household repairs to complex industrial machinery assembly. Their cost-effectiveness, paired with the ease of availability, allows both hobbyists and professionals to incorporate them seamlessly into their projects, fortifying bonds that hold entire structures together. Conducting research and relying on trusted manufacturers and suppliers for flat washers is advisable. The assurance of quality from authorized dealers impacts both the performance and safety of the constructions they are integrated into. Authenticity marks the difference between subpar and excellent outcomes, an essential factor experts insist upon when selecting the right flat washers. In conclusion, flat washers quietly but effectively execute roles critical to the success of countless projects. Through a trusted combination of experience and expertise, these unassuming components are safeguarded by their proven track record, extensive applicability, and foundational presence in engineering solutions. The journey from understanding their material composition to applying them effectively exemplifies the blend of knowledge and skill that characterizes both effective craftsmanship and innovative design.

In a more technological environment, such as the assembly of electrical panels, flat washers support not just structural stability but also address conductivity and insulation needs. Brass washers, for example, might be chosen for their superior electrical conductivity, while nylon washers would serve in non-conductive roles, preventing shorts and ensuring the safety and efficiency of the electrical system. The authoritative role flat washers play in engineering applications extends beyond their mere physical presence. They embody precision engineering principles, reflecting improvements in manufacturing techniques and material sciences. This alignment with advanced engineering validates their indispensable nature in construction and design projects. The trust bestowed upon these components is measurable by their ubiquitous presence in various applications, from everyday household repairs to complex industrial machinery assembly. Their cost-effectiveness, paired with the ease of availability, allows both hobbyists and professionals to incorporate them seamlessly into their projects, fortifying bonds that hold entire structures together. Conducting research and relying on trusted manufacturers and suppliers for flat washers is advisable. The assurance of quality from authorized dealers impacts both the performance and safety of the constructions they are integrated into. Authenticity marks the difference between subpar and excellent outcomes, an essential factor experts insist upon when selecting the right flat washers. In conclusion, flat washers quietly but effectively execute roles critical to the success of countless projects. Through a trusted combination of experience and expertise, these unassuming components are safeguarded by their proven track record, extensive applicability, and foundational presence in engineering solutions. The journey from understanding their material composition to applying them effectively exemplifies the blend of knowledge and skill that characterizes both effective craftsmanship and innovative design.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025