Exploring the Benefits of Stainless Steel Washers in Various Applications

11月 . 27, 2024 17:05 Back to list

Exploring the Benefits of Stainless Steel Washers in Various Applications

The Role of Washer Stainless Steel in Modern Industries

In recent years, the demand for durable, corrosion-resistant materials has surged across various industrial sectors. Among the materials that have risen to prominence is stainless steel, particularly in the form of washers. These unassuming components play a critical role in ensuring the reliability and longevity of various applications, from automotive to construction, and even medical devices. Understanding the significance of stainless steel washers can provide insights into their benefits and applications in modern industries.

What are Stainless Steel Washers?

Stainless steel washers are disk-shaped, flat components designed to distribute the load of a fastener, such as a nut or bolt, over a larger surface area. This distribution minimizes the risk of damage to the surface being fastened, improves the integrity of the joint, and prevents loosening caused by vibration. Their design and material properties make them ideal for various applications, especially in environments exposed to moisture, chemicals, or high temperatures.

Why Choose Stainless Steel?

One of the primary advantages of using stainless steel for washers is its excellent resistance to corrosion. Unlike other materials such as carbon steel, which can rust and degrade over time, stainless steel maintains its integrity even in harsh environments. This makes it an ideal choice for industries such as marine, automotive, and construction, where exposure to moisture and salt is common. Additionally, stainless steel washers have a higher tensile strength, meaning they can withstand greater forces without deforming, which is crucial for maintaining the stability of assemblies in demanding applications.

Applications of Stainless Steel Washers

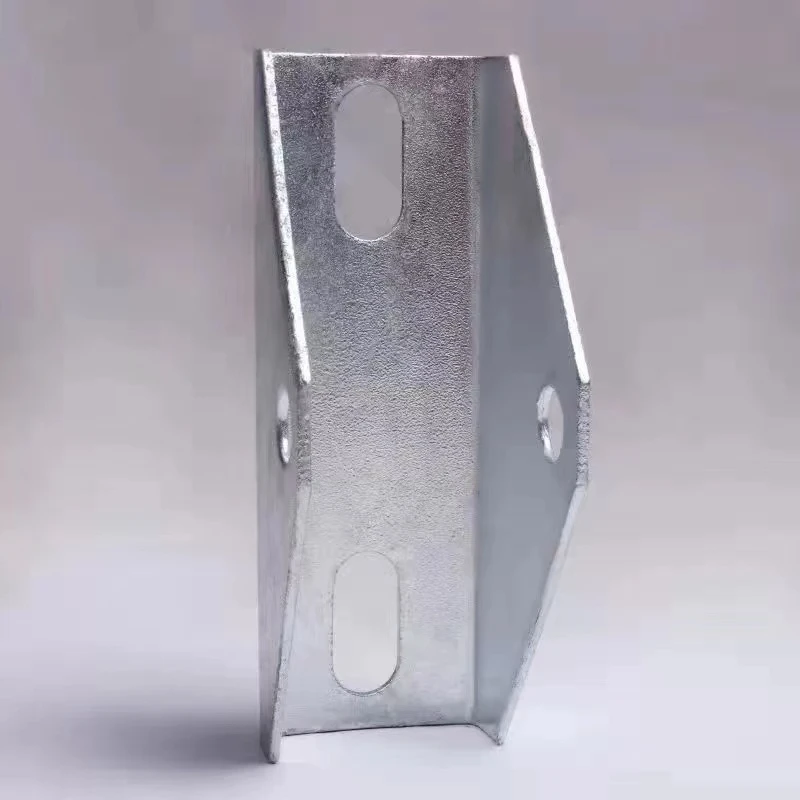

washer ss

The versatility of stainless steel washers extends across various industries. In the automotive sector, they are used in assembling brakes, engines, and other critical components, where their ability to withstand vibrations and corrosion is paramount. In construction, stainless steel washers are essential for roofing and structural applications, providing durability and safety to buildings that are subject to harsh weather conditions.

In the aerospace industry, the use of stainless steel washers is also noteworthy. Components must be lightweight yet strong, and stainless steel fits this requirement, ensuring the safety and performance of aircraft under extreme conditions. Moreover, in the medical field, where hygiene and corrosion resistance are critical, stainless steel washers are employed in surgical instruments and equipment, helping to maintain high standards of cleanliness during medical procedures.

The Future of Stainless Steel Washers

As technology advances, the manufacturing processes for stainless steel washers are evolving as well. Innovations such as 3D printing and advanced machining techniques are enabling the production of washers with enhanced precision and customized designs, meeting the specific needs of diverse industries. Furthermore, the growing emphasis on sustainability and environmental responsibility is driving manufacturers to explore eco-friendly production methods and recyclable materials, ensuring that stainless steel washers remain a vital component of modern engineering.

Conclusion

In conclusion, stainless steel washers are indispensable components across various industries, providing durability, reliability, and safety. Their resistance to corrosion, strength, and versatility make them suitable for an array of applications from automotive to aerospace. As we move toward a future that values sustainability and innovation, the demand for stainless steel washers is likely to grow, highlighting their essential role in advancing modern engineering and manufacturing practices. Understanding their importance is key to appreciating the intricacies of many systems that rely on this simple yet effective fastener component.

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025