Exploring Advanced Technologies for Sustainable Development and Innovation in Modern Society

10月 . 11, 2024 17:17 Back to list

Exploring Advanced Technologies for Sustainable Development and Innovation in Modern Society

Understanding the Core Concepts of MS1579520815 Standard

In today's fast-paced and increasingly interconnected world, standards play a crucial role in ensuring quality, safety, and efficiency across various industries. Among the numerous standards in circulation, MS1579520815 is particularly significant. This standard, while specialized, carries implications that extend across multiple sectors, including manufacturing, engineering, and technology. In this article, we will delve into the core principles of MS1579520815, its applications, and its impact on industry practices.

MS1579520815 is a specification developed to provide comprehensive guidelines for certain technical processes and materials. This standard aims to streamline operations, enhance product reliability, and ensure that all participants in the supply chain are aligned in their understanding and execution of best practices. As industries evolve, adapting standards like MS1579520815 helps organizations maintain competitiveness while upholding quality.

Understanding the Core Concepts of MS1579520815 Standard

Moreover, MS1579520815 emphasizes the importance of safety and compliance. In environments where machinery and electronic systems are prevalent, adhering to recognized standards is paramount. This standard incorporates safety protocols that protect not only workers but also products and the environment. Companies that comply with these guidelines are not only ensuring their own operational integrity but are also contributing to a broader culture of safety within their industry.

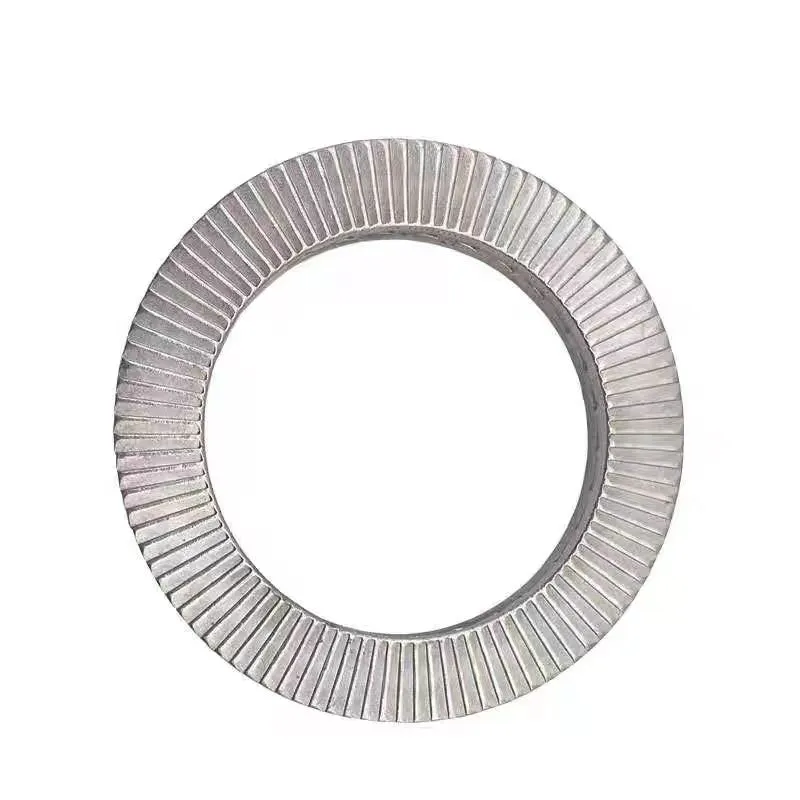

ms15795 815

The implementation of MS1579520815 can also lead to significant improvements in efficiency. By standardizing practices, organizations can reduce variability in their processes. This leads to more predictable outcomes, allowing businesses to optimize their operations. For instance, in manufacturing, standardized components can accelerate assembly times and reduce waste, ultimately leading to increased profitability. The approach fosters an environment where continuous improvement can thrive as organizations focus on enhancing their systems in alignment with the standard.

Training and education are also vital components of successfully implementing MS1579520815. Organizations must invest in their personnel, ensuring that employees understand the standard's requirements and how to apply them effectively. Training sessions, workshops, and ongoing education initiatives can help embed the principles of MS1579520815 into the company culture. As employees become more knowledgeable about the standard, they empower the organization to achieve higher levels of performance and compliance.

Furthermore, as industries face the growing challenges of globalization and technological advancement, standards like MS1579520815 offer a framework for resilience. In a world where supply chains are often stretched across multiple continents, having a uniform standard can protect against disarray caused by local regulations or varying quality measures. Organizations that adopt these standards may find themselves better positioned to respond to changes in the market, adapt to new technologies, and overcome potential disruptions.

In conclusion, MS1579520815 serves as a critical standard within various sectors, promoting safety, efficiency, and quality. As industries continue to advance and transform, aligning practices with recognized standards will be vital for success. By understanding and implementing MS1579520815, organizations can enhance their operations, improve product reliability, and foster a culture of excellence that ultimately benefits all stakeholders involved. In a world increasingly driven by connectivity and collaboration, adherence to such standards is more important than ever.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025