M14x1 Flange Nut with 205 Degree Angle for Enhanced Performance and Reliability

12月 . 09, 2024 23:29 Back to list

M14x1 Flange Nut with 205 Degree Angle for Enhanced Performance and Reliability

Understanding the M14x1 Flange Nut Specifications and Applications

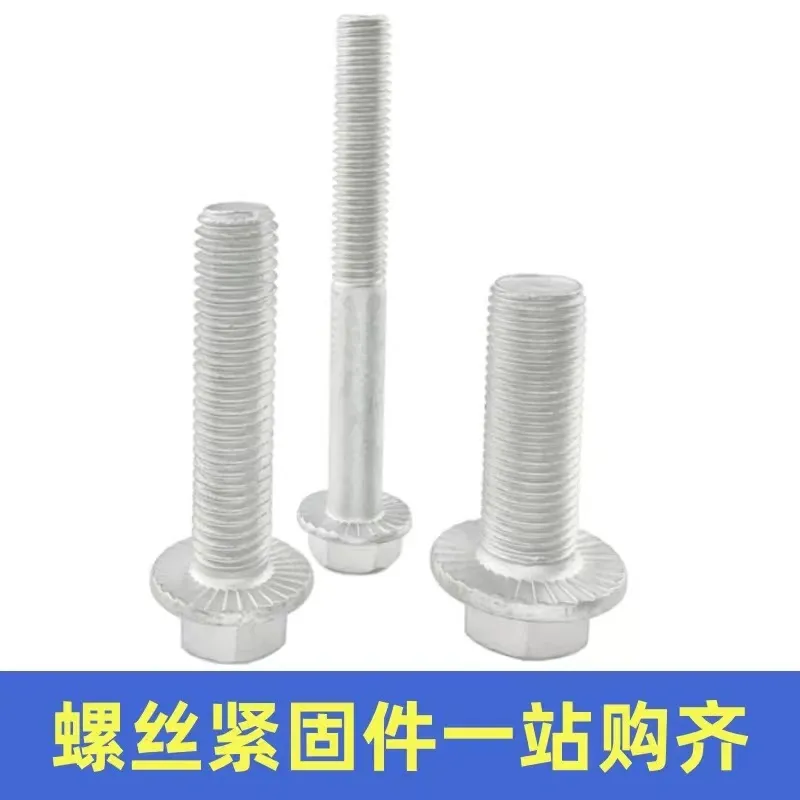

The M14x1 flange nut is an essential hardware component widely used in various engineering and mechanical applications. With a metric size designation, the M14 indicates that the nut has a nominal diameter of 14 millimeters, while the 1 refers to the pitch of the threads, which is 1 millimeter. The addition of the flange component distinguishes this type of nut from standard nuts, offering unique advantages that enhance its functionality and application.

What is a Flange Nut?

A flange nut is a type of nut that features a wide, integrated washer-like flange at its base. This design provides greater surface area, helping to distribute the load over a larger area when the nut is tightened. The flange reduces the risk of damage to the material being fastened, making it particularly useful for applications where standard nuts may risk pulling through the material or causing deformation.

Key Features of the M14x1 Flange Nut

1. Material Composition M14x1 flange nuts are typically made from various materials, including carbon steel, stainless steel, and other alloys. The choice of material depends on the specific requirements of the application, including factors like corrosion resistance, strength, and weight. Stainless steel offers excellent resistance to rust and corrosion, making it ideal for outdoor and marine applications.

2. Threading and Compatibility The M14x1 threading allows this flange nut to fit securely on M14 bolts and threaded rods with a pitch of 1 millimeter. Proper compatibility is crucial for ensuring robust connections and preventing issues like stripping or loosening under load.

3. Load Distribution The flange's broader base helps in distributing load more evenly across the surface. This is particularly beneficial in applications involving soft or thin materials where traditional nuts may cut into or deform the substrate.

4. Ease of Installation The design of the flange nut simplifies installation, as it can often be tightened without requiring an additional washer. This not only saves time during assembly but also reduces the overall number of parts needed for securing components.

m14x1 5 flange nut

Applications of the M14x1 Flange Nut

The versatility of the M14x1 flange nut allows it to be utilized in a wide range of applications

- Automotive Industry In automotive manufacturing and repair, the M14x1 flange nut is often used to secure critical components like engine parts, chassis elements, and suspension systems. Its strength and load distribution properties are essential in high-stress environments.

- Construction and Structural Applications In the construction sector, these flange nuts are utilized for fastening structural steel components, providing the necessary load-bearing capacity while ensuring stability in buildings and bridges.

- Heavy Machinery Industries such as agriculture and manufacturing use the M14x1 flange nut in heavy machinery and equipment assemblies. Its ability to withstand vibrations and shear forces makes it a reliable choice for these demanding environments.

- Home and DIY Projects For enthusiasts and DIYers, the M14x1 flange nut is commonly used in assembling furniture, garden equipment, and various home improvement tasks, thanks to its availability and ease of use.

Conclusion

In summary, the M14x1 flange nut is a robust and versatile component that plays a vital role across multiple industries. Its unique features, such as enhanced load distribution and ease of installation, make it an excellent choice for both professional applications and home projects. Understanding the specifications and applications of the M14x1 flange nut ensures that engineers and builders can utilize this essential hardware effectively, optimizing performance and safety in their projects.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025