hdg washers

12月 . 06, 2024 23:37 Back to list

hdg washers

Understanding HDG Washers Importance, Applications, and Benefits

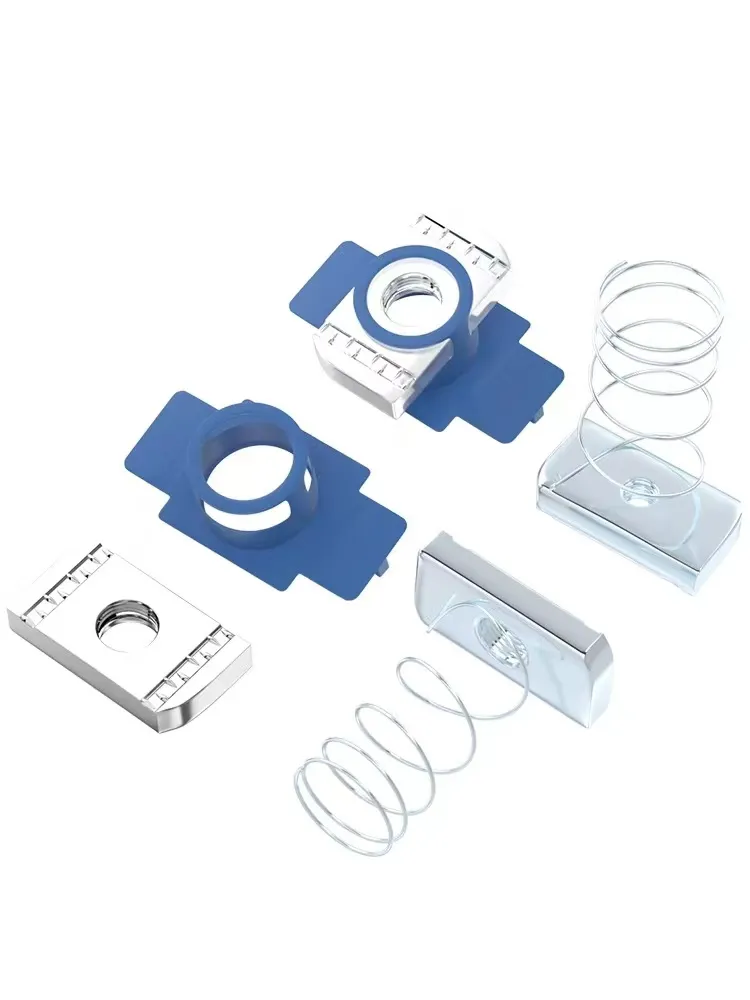

Hot-Dip Galvanized (HDG) washers play a vital role in many construction and manufacturing processes. These washers are essential components used to distribute the load of a threaded fastener, such as a bolt or screw, and to prevent damage to the surface being fastened. Their unique properties, stemming from the hot-dip galvanization process, make HDG washers particularly suitable for outdoor and industrial applications.

What is Hot-Dip Galvanization?

Hot-dip galvanization is a procedure that involves coating steel with a layer of zinc to protect it from corrosion. This method offers comprehensive coverage, including complex shapes and components, making it ideal for products exposed to harsh environments. The process typically involves cleaning the steel surface, pre-treating it, and immersing it in molten zinc. As a result, the zinc forms a metallurgically bonded layer that adheres well to the steel substrate, offering enhanced durability and longevity.

Applications of HDG Washers

HDG washers are primarily used in construction, automotive, and heavy machinery industries. Their corrosion resistance makes them a popular choice in environments that experience moisture, chemicals, or extreme weather conditions. For instance, in construction, HDG washers are commonly used with structural bolts and screws in steel buildings, bridges, and outdoor installations, where these components are subjected to significant external stress and potential corrosion.

In the automotive industry, HDG washers are employed in various applications, including fastening components in the chassis, suspension systems, and body panels. The ability of these washers to withstand environmental stressors is critical in ensuring vehicle safety and longevity.

hdg washers

Benefits of Using HDG Washers

One of the primary benefits of hot-dip galvanized washers is their excellent corrosion resistance. Unlike standard washers that may rust when exposed to moisture, HDG washers maintain their integrity and strength over time, significantly reducing the need for replacements. This quality is particularly beneficial in regions with high levels of humidity or in applications where components are routinely exposed to corrosive substances.

Another advantage is their cost-effectiveness. While the initial cost of HDG washers may be higher than that of uncoated alternatives, the long-term savings due to reduced maintenance and replacement costs often outweigh this initial investment. In addition, the extended lifespan of these washers contributes to the overall cost-effectiveness of a project, making them a preferred choice for budget-conscious businesses.

Moreover, the hot-dip galvanization process offers excellent adherence and toughness of the zinc coating. The unique bonding reduces the likelihood of peeling or chipping, ensuring that the washers continue to perform effectively throughout their service life.

Conclusion

In summary, HDG washers are critical components that provide significant benefits in various industrial applications. Their robust corrosion resistance, cost-effectiveness, and durability make them an ideal choice for situations demanding reliability against environmental factors. As industries continue to evolve and place greater emphasis on quality and longevity, hot-dip galvanized washers are likely to remain a staple for construction, automotive, and heavy machinery sectors. Investing in HDG washers ultimately contributes to enhancing the performance and durability of fastened assemblies, ensuring safer and more reliable infrastructures across the board.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025