t stud bolt

Nov . 19, 2024 10:10 Back to list

t stud bolt

Understanding T-Stud Bolts Essential Components in Structural Applications

In the world of construction and engineering, the importance of reliable fastening systems cannot be overstated. Among various fastening options, T-stud bolts have carved out a significant niche due to their unique design and functional versatility. This article delves into the characteristics, uses, and advantages of T-stud bolts, illustrating why they are essential components in structural applications.

What Are T-Stud Bolts?

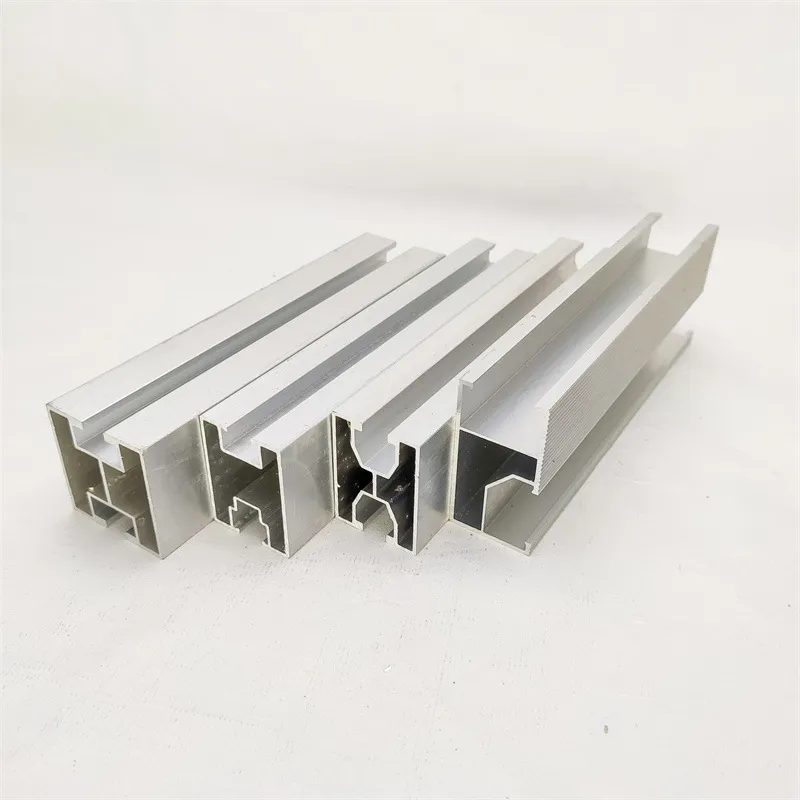

T-stud bolts, also known as T-headed bolts or wedge bolts, are specialized fasteners characterized by a T-shaped head and a threaded shaft. The design allows for secure connections in applications where traditional bolt heads may be inadequate. The T-shape provides a larger bearing surface than standard bolts, making them ideal for heavy-duty applications. These bolts are typically made from high-strength materials such as stainless steel, carbon steel, or alloy steel, ensuring they can withstand significant loads and resist corrosion.

Applications of T-Stud Bolts

T-stud bolts find application in various industries, including construction, automotive, and manufacturing. Here are some of the key areas where T-stud bolts are used

1. Construction In structural engineering, T-stud bolts are frequently used to secure heavy steel frames and precast concrete elements. Their ability to provide a strong anchor point makes them suitable for high-rise buildings, bridges, and industrial facilities.

2. Woodworking T-stud bolts can secure wooden beams and components, especially in timber-frame construction. They offer a robust solution for creating strong joints that can withstand environmental stresses.

3. Manufacturing In the production of machinery and equipment, T-stud bolts are used to hold components together under mechanical loads. Their reliability ensures that critical parts remain securely fastened throughout the machinery's operational life.

t stud bolt

4. Automotive Industry T-stud bolts can also be found in the automotive sector, where they are used to assemble various vehicle parts. Their strength and durability make them ideal for high-stress applications in cars and trucks.

Advantages of T-Stud Bolts

The unique design and functionality of T-stud bolts offer several advantages that make them a preferred choice in many applications

1. Load Distribution The T-shaped head provides a larger surface area for load distribution, reducing localized stress on materials. This characteristic is particularly important in heavy-load scenarios, where minimizing the risk of failure is paramount.

2. Ease of Installation T-stud bolts can be installed more easily than traditional fasteners, especially in tight spaces. The design allows for quick positioning and securing, leading to faster assembly times and increased overall efficiency.

3. Versatility T-stud bolts can be used with various materials, including metals and wood, making them suitable for diverse applications. This versatility allows engineers and builders to integrate them into different designs seamlessly.

4. Corrosion Resistance When made from stainless or treated steel, T-stud bolts demonstrate excellent corrosion resistance, ensuring longevity in harsh environments. This feature is critical in outdoor applications or areas prone to moisture.

Conclusion

In summary, T-stud bolts are vital components in numerous industries, providing robust fastening solutions that enhance the structural integrity of various applications. Their unique design, ease of installation, and ability to withstand substantial loads make them an invaluable asset in construction, manufacturing, and automotive sectors. As engineering demands continue to evolve, the role of T-stud bolts will undoubtedly remain significant, affirming their importance in building the infrastructures of tomorrow. For engineers, contractors, and manufacturers alike, understanding the functionalities and benefits of T-stud bolts is essential in making informed decisions about fastening systems in their projects.

Latest news

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025