m8 bolt

Nov . 22, 2024 06:53 Back to list

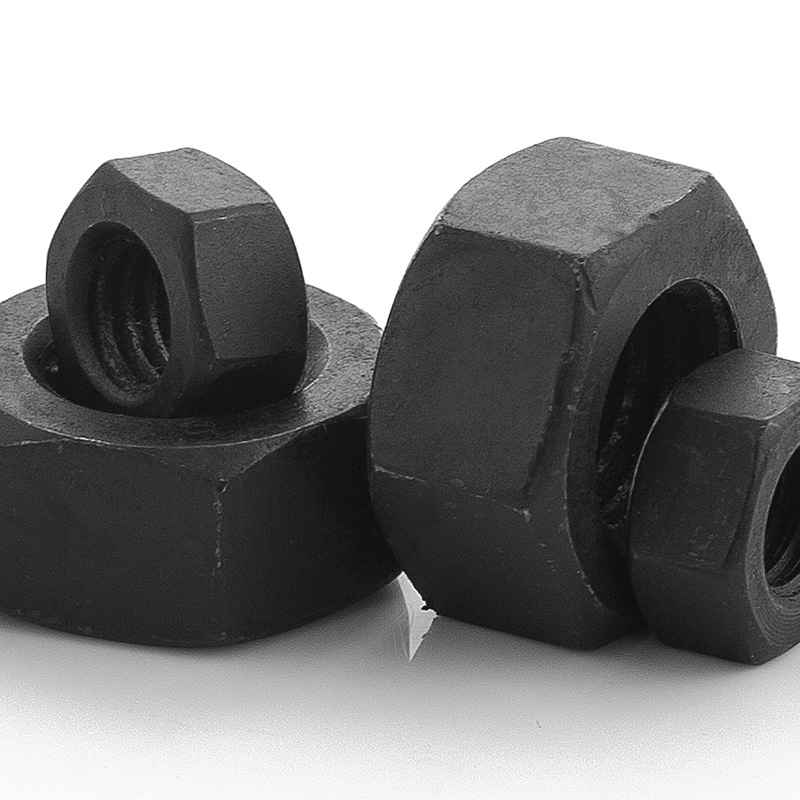

m8 bolt

Understanding M8 Bolt The Essential Fastener in Engineering

When it comes to mechanical engineering and construction, fasteners play a critical role in ensuring the structural integrity and reliability of various assemblies. One such fastener that is widely used across multiple industries is the M8 bolt. Understanding the specifications, applications, and benefits of M8 bolts can help engineers and constructors choose the right fastener for their projects.

What is an M8 Bolt?

An M8 bolt refers to a metric bolt with a nominal diameter of 8 millimeters. The designation 'M' signifies that the bolt conforms to the metric system, which is the most widely adopted measurement system around the globe. M8 bolts typically come in various lengths and can have different thread pitches, but the most common thread pitch for M8 bolts is 1.25 mm.

M8 bolts can be categorized into different grades, which determine their strength and suitability for specific applications. Common grades are 8.8, 10.9, and 12.9, with grade 8.8 being the most prevalent in general applications. The grade number indicates the ultimate tensile strength and yield strength of the bolt; higher numbers indicate stronger bolts.

Material and Coatings

M8 bolts are typically made from carbon steel, but they can also be manufactured from stainless steel, alloy steel, and other materials based on their intended use. The surface finish and coatings applied to these bolts play a significant role in their performance. For example, zinc plating is often used to enhance corrosion resistance, making them suitable for outdoor environments. Similarly, galvanized coatings provide additional protection against rust and are favored in construction and landscaping applications.

Applications of M8 Bolts

m8 bolt

M8 bolts find a variety of applications in different fields, including automotive, aerospace, construction, and machinery. They are widely used in securing components, joining structural elements, and assembling machinery. In automotive applications, M8 bolts may be found holding together engine components, suspension systems, and chassis structures. Additionally, in construction, they are often used to fasten steel beams, secure brackets, and connect various structural elements in buildings and bridges.

Their versatility and robust design make them a preferred choice in many mechanical assemblies. For instance, M8 bolts are ideal for use in scenarios that require high clamping force and resistance to shear loads. This makes them especially useful in applications where durability and longevity are critical.

Advantages of Using M8 Bolts

One of the main advantages of using M8 bolts is their availability. Due to their widespread use, M8 bolts can be easily sourced from various suppliers, making them a convenient choice for many projects. Moreover, the standardization of metric bolts means that they can be readily interchanged with other metric fasteners, simplifying inventory management.

Another advantage is the ease of installation. M8 bolts are compatible with a range of tools, such as wrenches and socket sets, allowing for quick and efficient assembly. Their design also minimizes the risk of stripping or damaging the threads, provided they are used correctly.

Conclusion

In summary, M8 bolts are an essential component in various industries due to their strength, versatility, and ease of use. With their standardized measurements and wide availability, they serve as a reliable fastener choice for many engineering and construction applications. Understanding the specifications and applications of M8 bolts not only aids in selection but also enhances the overall quality and reliability of the assembled products. Whether you are a seasoned engineer or a DIY enthusiast, knowing about M8 bolts is crucial for achieving successful and durable outcomes in your projects.

Latest news

-

Similarities and Differences Between Plain Washer and Spring Washer - Fastener Comparison Guide

NewsJun.10,2025

-

Effortless Installation Self-Drilling Window Screws - Fast, Secure, and Durable Fasteners

NewsJun.10,2025

-

Self Drilling Stucco Screws for Fast, Secure Installation Self Tapping & Self-Tapping Fasteners

NewsJun.10,2025

-

Premium Hot Dipped Galvanized Self Tapping Screws - Durable Corrosion Resistance

NewsJun.09,2025

-

Discover M12 Weld Stud Benefits & Applications Guide

NewsJun.09,2025

-

M25 Stainless Steel Washers High-Durability Fasteners for Corrosion Resistance

NewsJun.09,2025