M10x1 Flange Nut with 200% Performance for Enhanced Grip and Stability

Set . 28, 2024 23:07 Back to list

M10x1 Flange Nut with 200% Performance for Enhanced Grip and Stability

Understanding the M10x1 0 Flange Nut A Comprehensive Guide

When it comes to fastening components together, flange nuts are an often-overlooked but critical element in engineering and construction. Among these, the M10x1 0 flange nut is particularly notable for its unique specifications and applications. This article will explore the features, benefits, applications, and best practices for using the M10x1 0 flange nut, helping you make informed choices for your projects.

What is an M10x1 0 Flange Nut?

The designation M10x1 0 might seem complex at first glance, but it breaks down into understandable components. The M10 indicates that the nut is designed to fit an M10 bolt, which has a nominal diameter of 10 millimeters. The 1 refers to the pitch of the thread, which is in this case, 1 millimeter. Thus, it is a standard metric sizing specification. The 200 might suggest a strength rating or standard, indicating its suitability for various applications.

The flange aspect of this nut contributes significantly to its performance. The flange is essentially a wide rim that distributes the load more evenly across a material's surface. This design feature reduces the chance of damage to the base material and enhances the nut's locking capabilities by increasing friction against the surface.

Features of M10x1 0 Flange Nuts

1. Load Distribution The flange design allows for better load distribution, which minimizes the risk of stripping and provides a more stable fastening solution. 2. Material and Finish Options M10x1 0 flange nuts are available in various materials, including steel, stainless steel, and even brass. Each material offers different levels of corrosion resistance, strength, and aesthetic considerations.

3. Thread Design With its coarse thread, the M10x1 0 nut provides superior gripping capability compared to finer threads, making it suitable for more challenging applications.

4. Ease of Use These nuts are easier to install, especially in tight spaces, due to their integral flange that acts as a washer, eliminating the need for an additional component.

Benefits of Using M10x1 0 Flange Nuts

1. Versatility M10x1 0 flange nuts can be used in numerous applications, from automotive to construction and household items. Their adaptability makes them a favorite among engineers and DIY enthusiasts alike.

2. Enhanced Stability Thanks to the load distribution offered by the flange, these nuts help maintain stability in assembled structures, reducing the likelihood of fastener loosening over time.

3. Reduced Material Damage The flange protects the underlying material from damage caused by torque or tension, which is particularly important when working with softer materials.

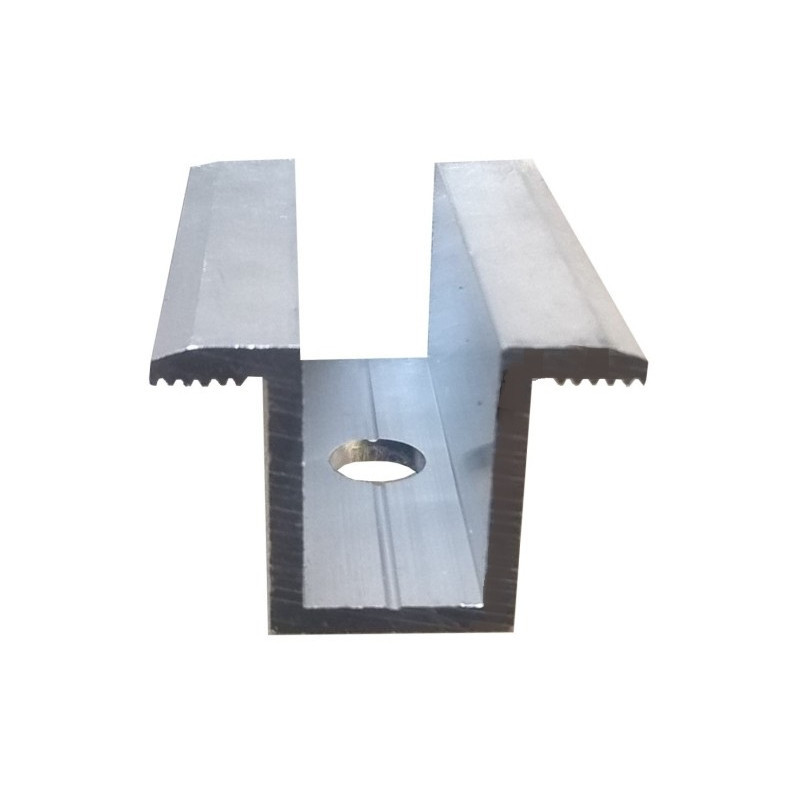

m10x1 0 flange nut

4. Cost-Effectiveness Given their robust design and effectiveness, M10x1 0 flange nuts often prove to be a cost-effective solution, reducing the need for additional washers and other fastening components.

Applications of M10x1 0 Flange Nuts

The versatility of the M10x1 0 flange nut comes into play across numerous fields

- Automotive Industry Used in vehicle assembly to ensure that components remain securely fastened despite the vibrations and stress experienced on the road. - Construction Ideal for bolting together heavy machinery and structural components, these nuts provide a reliable fastening solution in demanding environments.

- Furniture Manufacturing Many furniture pieces utilize these nuts due to their ability to hold together assemblies without damaging wood or composite materials.

- Electronics Employed in securing parts within electronic devices, the flange nut's design helps protect sensitive components.

Best Practices for Using M10x1 0 Flange Nuts

1. Proper Torque Levels Always adhere to recommended torque specifications to avoid damaging threads or over-stressing the nut.

2. Surface Preparation Ensure that the assembled surfaces are clean to allow the flange to grasp securely.

3. Regular Inspections Regularly check for signs of loosening or wear, especially in high-vibration environments.

4. Choosing the Right Material Account for the environment in which the nut will be used to select a corrosion-resistant material if necessary.

Conclusion

The M10x1 0 flange nut is a prime example of innovative engineering in fasteners. Its load-distributing flange increases stability and reliability, making it a valuable component across various industries. Understanding its features, benefits, and applications can help you optimize your fastening solutions, ensuring the safety and durability of your projects. Whether you’re an engineer or a DIY enthusiast, the M10x1 0 flange nut deserves a prominent place in your toolkit.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025