fastener

Set . 04, 2024 11:27 Back to list

fastener

The Importance of Fasteners in Modern Engineering

Fasteners are integral components in various construction and engineering projects, serving the vital function of joining two or more objects together securely. From everyday items like furniture and appliances to critical applications in the automotive and aerospace industries, fasteners play a crucial role in ensuring structural integrity and functionality. Understanding the diversity and significance of fasteners can illuminate their impact on design and manufacturing processes.

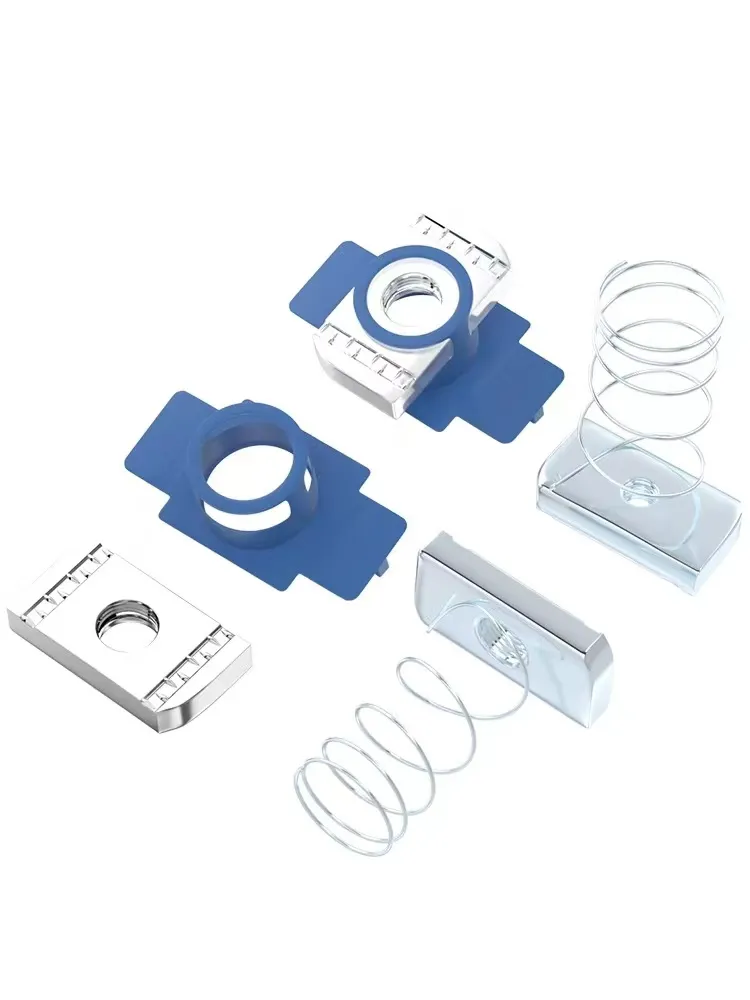

Fasteners come in many forms, with bolts, screws, nuts, washers, and rivets being among the most commonly used types. Each type serves a specific purpose and is selected based on factors such as the materials being joined, the required load-bearing capacity, and environmental conditions. For example, bolts are often utilized in heavy-duty applications where a strong, removable connection is necessary. Conversely, screws are employed for lighter tasks, providing a more permanent solution.

The choice of fastener material is equally important. Fasteners are typically made from steel, stainless steel, aluminum, brass, or plastic. Each material offers unique properties, such as corrosion resistance, strength, and weight, that influence the selection process. In environments subject to moisture or corrosive elements, stainless steel fasteners may be preferred for their durability and resistance to rust. In contrast, lightweight aluminum fasteners can be used in aerospace applications where minimizing weight is crucial.

fastener

Fastener design and installation also play a critical role in ensuring reliability and performance. Engineers must consider factors such as tensile strength, torque specifications, and the potential for fatigue or failure under stress. Proper installation is essential; improperly installed fasteners can lead to mechanical failures, safety hazards, and costly repairs. Innovations such as pre-assembled fastening systems and automated installation tools are transforming how fasteners are used, enhancing efficiency and precision in manufacturing processes.

The evolution of fastener technology has led to the development of specialized fasteners that address specific industry needs. For instance, in the construction industry, heavy-duty anchors are designed to secure structures in place, while vibration-resistant fasteners are used in automotive applications to withstand extreme conditions. Advances in materials science, such as the use of composite materials, are paving the way for lighter, stronger fasteners that can enhance overall system performance.

In conclusion, fasteners are much more than simple mechanical components; they are essential elements that contribute to the safety, efficiency, and longevity of a myriad of products and structures. As technology continues to advance, the fastener industry will likely see further innovations that enhance performance and expand the possibilities for engineering and design. Emphasizing the importance of choosing the right fasteners and understanding their applications is crucial for professionals in the field, ensuring the successful execution of projects across various domains.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025