5 8 flange nut

Dic . 22, 2024 03:37 Back to list

5 8 flange nut

Understanding the Importance of 5 8% Flange Nut in Engineering Applications

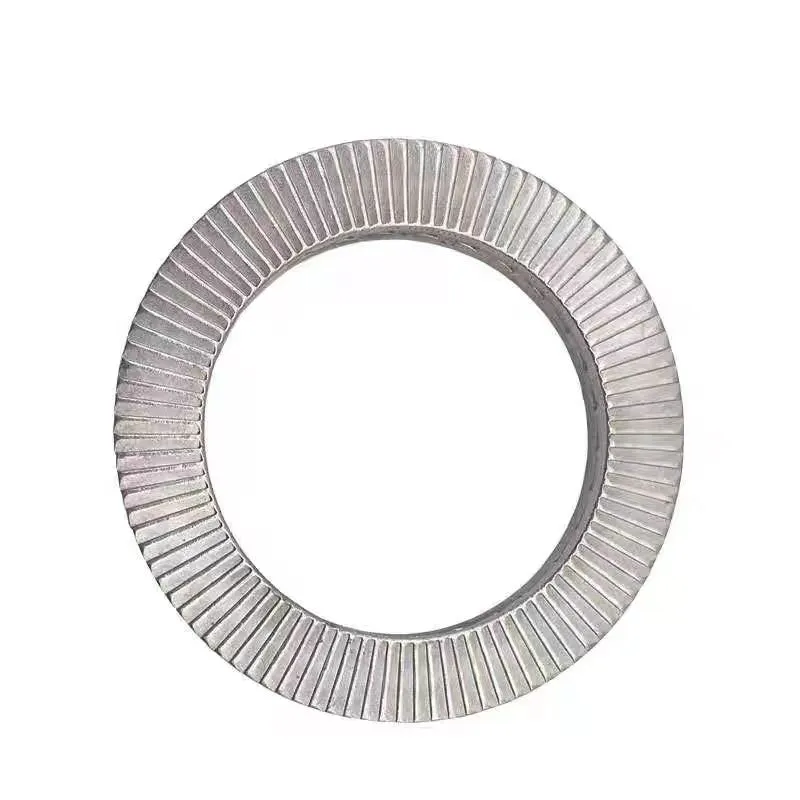

Flange nuts are critical components in various engineering and construction applications, playing a vital role in securing and stabilizing elements within a structure. Among the numerous types of flange nuts available in the market, the 5 8% flange nut has garnered attention due to its unique properties and applications. This article explores the characteristics, uses, advantages, and installation techniques of the 5 8% flange nut.

Characteristics of the 5 8% Flange Nut

The 5 8% flange nut features a wide, circular flange that increases the bearing surface against the object being secured, distributing the load more evenly than standard nuts. This design minimizes the risk of damaging the assembly, especially in softer materials. The percentage figures in the name often reference specific standards or materials that conform to certain structural requirements, highlighting the nut's ability to withstand various stresses and environmental factors.

Applications of the 5 8% Flange Nut

The versatility of the 5 8% flange nut makes it suitable for a broad range of applications across many industries. It is commonly used in construction, automotive, aerospace, and manufacturing sectors. For instance, in construction, flange nuts are essential in securing structural steel components. Their increased surface area provides enhanced holding power, thereby creating more resilient joints. In the automotive industry, these nuts are used in various assemblies where vibrations are common, ensuring that the connections do not loosen over time.

Advantages of the 5 8% Flange Nut

5 8 flange nut

One of the primary advantages of the 5 8% flange nut is its ability to resist loosening under vibration. The flange design, combined with the nut's robust material composition, allows it to maintain a strong grip even in challenging conditions. Additionally, the flange nut's increased surface area reduces the chances of damage to the mating surface, which is particularly beneficial in applications involving softer metals or composites.

Another significant advantage is the ease of installation. The design of the flange nut enables it to be easily tightened, often without the need for washers. This not only simplifies the assembly process but also reduces the number of components required in a given application, streamlining both manufacturing and maintenance efforts.

Installation Techniques

Installing a 5 8% flange nut requires adherence to specific procedures to ensure optimal performance. First and foremost, it is crucial to select the correct size of nut to match the bolt or screw being used. The flange should sit flat against the surface being secured, providing maximum contact.

When tightening the flange nut, it is recommended to use a calibrated torque wrench to achieve the manufacturer’s specified torque setting. This helps avoid over-tightening, which could potentially strip threads or compress assembly materials beyond their limits. It’s also essential to periodically check the tightness of flange nuts in applications subject to significant vibrations, ensuring they remain securely fastened over time.

Conclusion

The 5 8% flange nut exemplifies the advancements in fastening technology, providing a reliable solution for a variety of engineering challenges. Its unique design, coupled with its ease of use and resistance to loosening, makes it an invaluable component in many industries. As engineers and manufacturers continue to seek ways to improve the reliability and efficiency of their assemblies, the importance of high-quality fasteners like the 5 8% flange nut will only continue to grow. When considering materials and components for future projects, investing in reliable fastening solutions is paramount to achieving lasting success.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025