metal lock washer

Feb . 04, 2025 04:39 Back to list

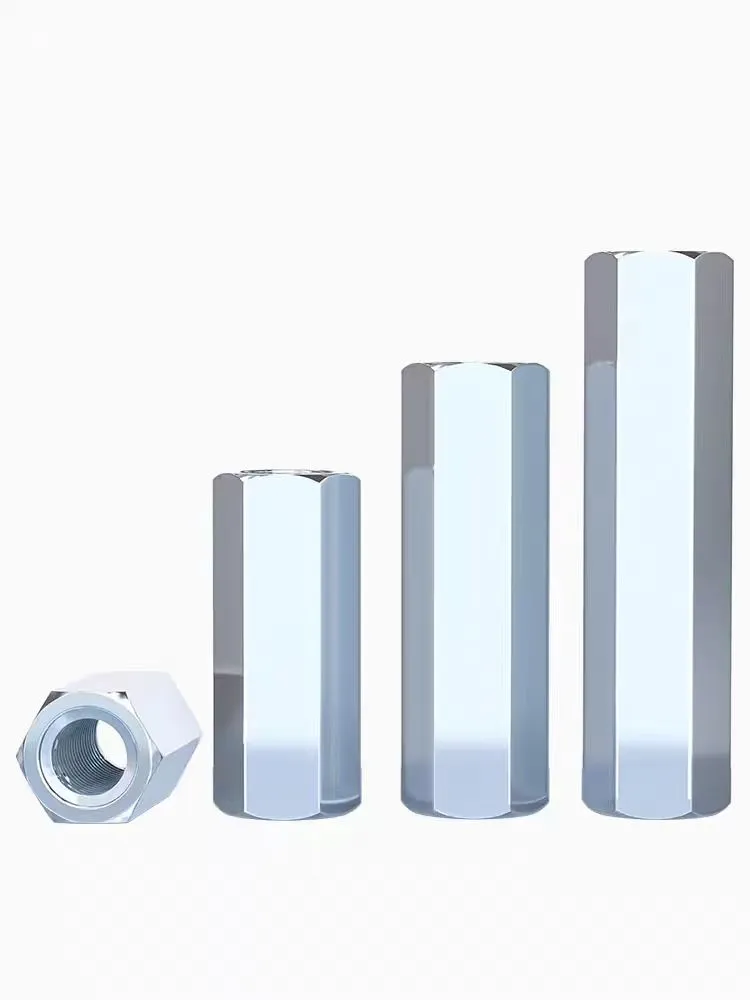

metal lock washer

Metal lock washers are an essential component in the world of hardware, offering unique advantages that cater to a multitude of industrial applications. Recognized for their effectiveness in fastener assemblies, metal lock washers ensure that nuts and bolts remain secure under stress, vibration, and temperature fluctuations, which is crucial for maintaining the integrity and safety of mechanical assemblies.

Trustworthiness in the use of metal lock washers also relies heavily on rigorous testing and adherence to industry standards. Many manufacturers put their lock washers through stress tests, corrosion resistance assessments, and load-bearing evaluations to ensure durability and effectiveness. Authenticity is guaranteed by compliance with standards set by organizations such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), which outline specifications for dimensions and materials. In practice, metal lock washers have become indispensable in sectors such as automotive, aerospace, and construction. In the automotive industry, for instance, these washers are critical in ensuring that assemblies can withstand the constant vibrations and shocks encountered on the road. In aerospace, where the stakes are extraordinarily high, lock washers provide reassurance that each fastened component contributes to the overall safety of the aircraft. Similarly, in the construction industry, durability and reliability are paramount, and lock washers help maintain structural integrity over time. For consumers considering metal lock washers, the authority of the supplier is a significant factor. Established brands with a track record of producing high-quality components offer peace of mind. Buyers are encouraged to look for detailed product specifications and customer testimonials that reflect authentic experiences, underlining the product's capacity to meet or exceed expectations. Ultimately, the reliability of metal lock washers is a combination of material excellence, precision engineering, and adherence to best practices. Whether you're a seasoned engineer or a DIY enthusiast, understanding these factors will significantly enhance the effectiveness of your projects, ensuring both safety and durability in your applications.

Trustworthiness in the use of metal lock washers also relies heavily on rigorous testing and adherence to industry standards. Many manufacturers put their lock washers through stress tests, corrosion resistance assessments, and load-bearing evaluations to ensure durability and effectiveness. Authenticity is guaranteed by compliance with standards set by organizations such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), which outline specifications for dimensions and materials. In practice, metal lock washers have become indispensable in sectors such as automotive, aerospace, and construction. In the automotive industry, for instance, these washers are critical in ensuring that assemblies can withstand the constant vibrations and shocks encountered on the road. In aerospace, where the stakes are extraordinarily high, lock washers provide reassurance that each fastened component contributes to the overall safety of the aircraft. Similarly, in the construction industry, durability and reliability are paramount, and lock washers help maintain structural integrity over time. For consumers considering metal lock washers, the authority of the supplier is a significant factor. Established brands with a track record of producing high-quality components offer peace of mind. Buyers are encouraged to look for detailed product specifications and customer testimonials that reflect authentic experiences, underlining the product's capacity to meet or exceed expectations. Ultimately, the reliability of metal lock washers is a combination of material excellence, precision engineering, and adherence to best practices. Whether you're a seasoned engineer or a DIY enthusiast, understanding these factors will significantly enhance the effectiveness of your projects, ensuring both safety and durability in your applications.

Next:

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025