Understanding the Function and Applications of Disc Spring Washers in Engineering

Nov . 26, 2024 18:34 Back to list

Understanding the Function and Applications of Disc Spring Washers in Engineering

Understanding Disc Spring Washers An Overview

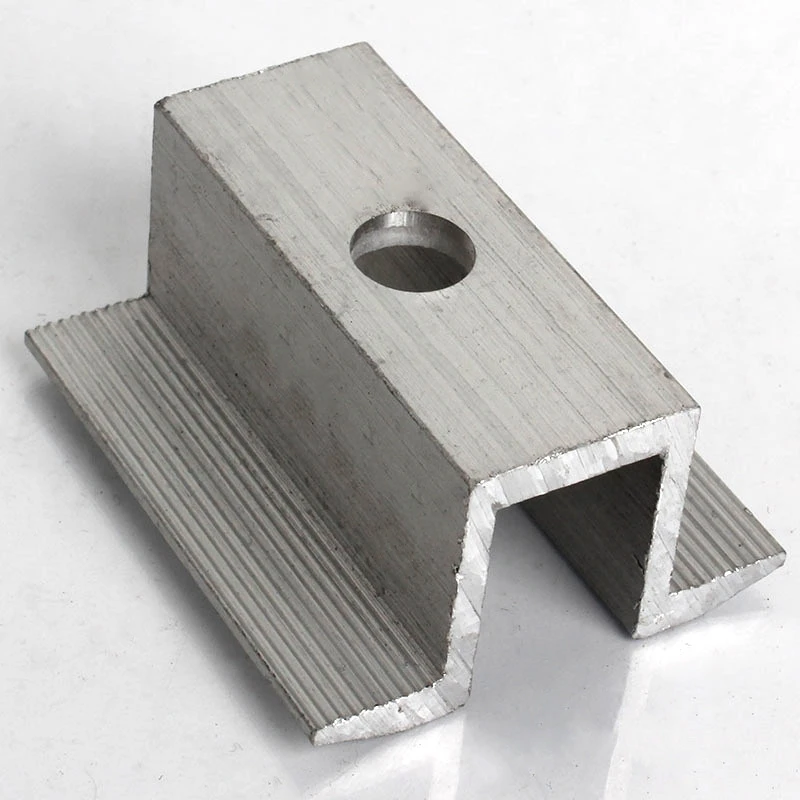

Disc spring washers, also known as Belleville washers, are a crucial component widely utilized in various mechanical applications. These specialized washers are designed to provide a high degree of flexibility and load retention, making them indispensable in numerous engineering fields.

What is a Disc Spring Washer?

A disc spring washer is essentially a conical-shaped spring that exhibits unique properties when subjected to axial loads. The design of a disc spring allows it to store energy in a compact space, providing a high force or tension in a limited volume. This characteristic makes disc spring washers suitable for applications where space is at a premium.

Design and Construction

Disc spring washers are manufactured from high-quality materials, typically steel, stainless steel, or other alloys that ensure durability and resilience. The manufacturing process often involves heat treatment to enhance their strength and fatigue resistance. The washer's geometry, characterized by its conical shape, enables it to flex and compress, thus providing effective load distribution.

The thickness and diameter of disc springs can vary depending on application requirements. Manufacturers can tailor these specifications to meet specific loading conditions, making them a versatile solution for engineers and designers.

Applications of Disc Spring Washers

Disc spring washers are utilized in a wide range of applications, including

1. Automotive Industry In vehicles, disc spring washers are used in suspensions, clutch assemblies, and engine mounts, where they help maintain consistent pressure and reduce the risk of mechanical failure.

disc spring washer

2. Aerospace The aerospace sector employs disc springs in various components where weight savings and reliability are critical. They play a role in securing bolts and maintaining proper tension in critical assemblies.

4. Electronics In electronic devices, disc spring washers are essential for grounding, maintaining connection integrity, and absorbing shocks caused by physical impacts.

Advantages of Using Disc Spring Washers

1. Space Efficiency Their unique design allows for a significant load capacity in a compact space, making them ideal for applications with limited room.

2. Load Retention Disc spring washers can adapt to changes in load, effectively maintaining clamping power even under varying conditions. This characteristic prevents hardware from becoming loose over time.

3. Fatigue Resistance Due to their design and material composition, disc springs exhibit excellent fatigue resistance, allowing them to endure numerous cycles of compression without failure.

4. Versatility Disc spring washers can be used in conjunction with traditional flat washers or on their own, depending on the application, providing flexibility in design and assembly.

Conclusion

Disc spring washers are a vital element in the mechanical and engineering landscape, offering significant advantages in load retention, space efficiency, and durability. Their adaptability across various industries highlights their importance in ensuring the reliability and longevity of critical components. As technology advances, the applications and designs of disc spring washers will likely continue to evolve, further cementing their role in modern engineering solutions. Engineers and designers can rely on these components to enhance performance and safety in their projects, making them a staple in mechanical assembly and maintenance.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025