m12 washer diameter

Oct . 08, 2024 00:12 Back to list

m12 washer diameter

Understanding M12 Washer Diameter A Comprehensive Overview

When it comes to mechanical assemblies and construction applications, the importance of selecting the right components cannot be overstated. One such essential component is the washer, specifically the M12 washer. The M in M12 refers to the metric sizing system, where 12 denotes the nominal diameter of the screw or bolt it is intended to fit, measured in millimeters. In this article, we will delve into the specifications of M12 washers, their applications, and why the diameter plays a crucial role in ensuring reliability and performance in various settings.

What are M12 Washers?

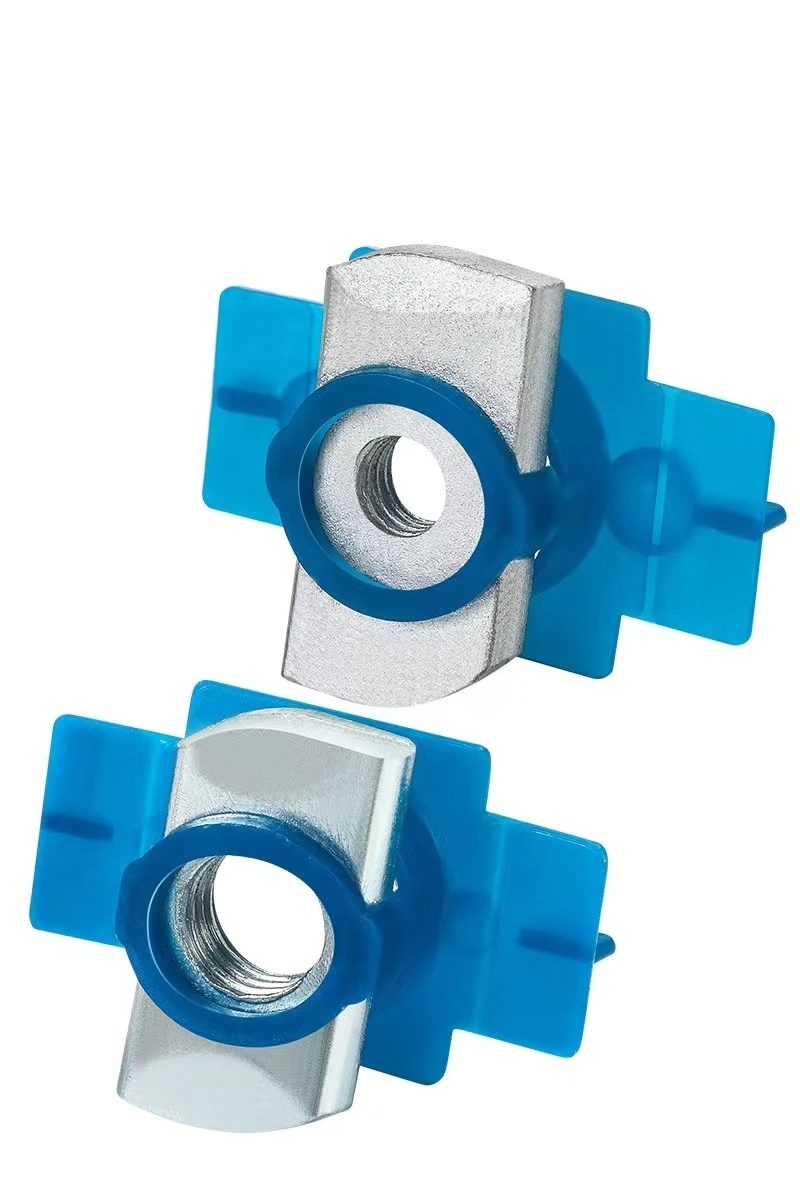

M12 washers are flat, ring-shaped pieces of metal or plastic that are used in conjunction with M12 bolts or screws. They serve multiple purposes, including distributing the load of a fastener, preventing damage to the surface being fastened, and providing a smooth surface to facilitate the tightening of nuts and bolts. The diameter of the washer is vital because it directly affects its efficiency and effectiveness in application.

Specifications of M12 Washers

Typically, an M12 washer has an inner diameter that accommodates an M12 bolt, with a standard size of approximately 12 mm. The outer diameter can vary, but it commonly falls between 24 mm to 30 mm, depending on the specific washer type and application. Furthermore, there are different styles of M12 washers, including flat washers, spring washers, and split washers, each serving unique functions.

- Flat Washers These are the most common and are used to provide a smooth surface for load distribution. - Spring Washers Also known as lock washers, they are used to prevent the loosening of screws due to vibrations. - Split Washers Similar to spring washers, they provide a locking mechanism to resist loosening.

The choice of washer thickness also contributes to its performance; thicker washers can provide better load distribution but may be unsuitable for compact installations.

m12 washer diameter

Applications of M12 Washers

M12 washers find extensive applications across various industries. They are commonly used in

1. Construction For building frameworks, platforms, and other structural elements. 2. Automotive In securing components of vehicles, ensuring safety and stability. 3. Manufacturing In machinery and machinery assembly, where bolts and screws are prevalent. 4. Furniture Assembly In the making of sturdy furniture that can withstand dynamic loads.

The right diameter, combined with the appropriate washer type, enhances safety and ensures the longevity of the structures or devices they are a part of.

Importance of Correct Sizing

Selecting a washer with the correct diameter is critical. A washer that is too small may not fully engage with the bolt or nut, leading to inefficient load distribution and potential failure. On the other hand, an overly large washer may not fit within the application space leading to installation difficulties.

In conclusion, the M12 washer diameter is a key factor in mechanical and construction applications. Understanding the specifications and appropriate use of these washers ensures that assemblies are secure and functional. Whether you are a DIY enthusiast or a seasoned professional, paying attention to the details can save time, money, and effort in the long run. As you plan your next project, remember that the small components often play the biggest roles.

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025