fastener suppliers

Déc . 22, 2024 21:00 Back to list

fastener suppliers

The Importance of Fastener Suppliers in Modern Industry

Fasteners are vital components in various industries, serving to hold different elements together securely. From construction to automotive manufacturing and electronics, fasteners come in various types, materials, and sizes, playing an essential role in ensuring the structural integrity and functionality of products. Fastener suppliers are the unsung heroes in this ecosystem, providing the necessary parts to keep industries running smoothly and efficiently.

Types of Fasteners

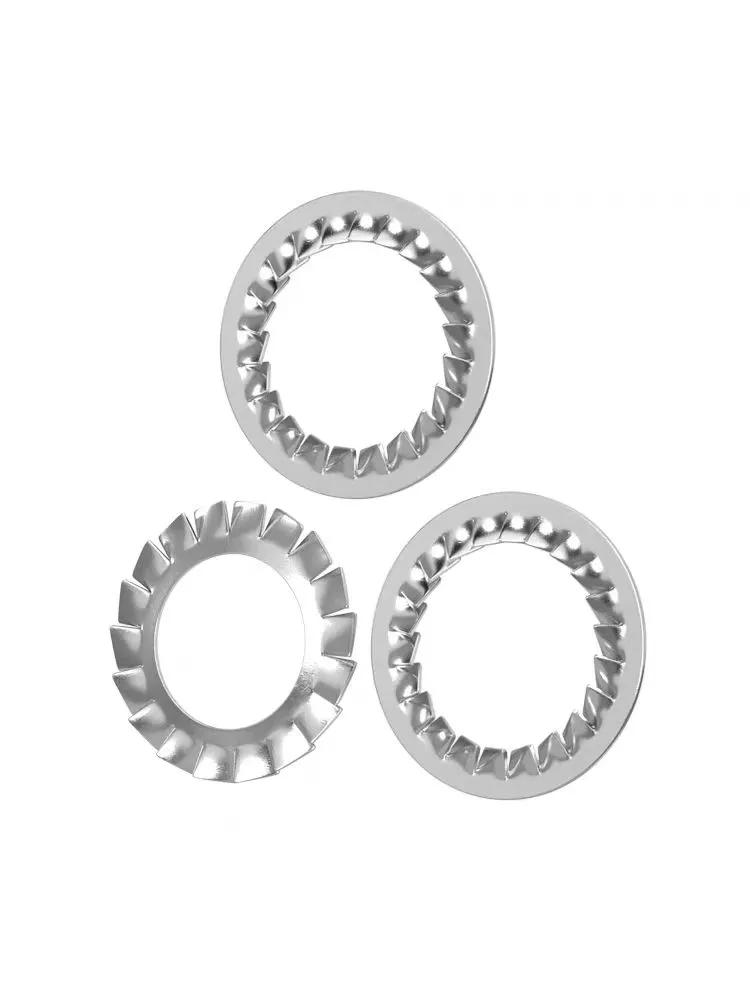

Fasteners can be categorized into several types, including bolts, screws, nuts, washers, rivets, and anchors. Each type serves a specific purpose and is used based on the requirements of a particular application. For instance, bolts are typically used for heavy-duty applications due to their strength, while screws are often utilized in lighter assemblies. Washers are essential to distribute load and prevent surface damage, while rivets are permanent fasteners used in applications requiring a strong bond without the need for tools during installation.

The Role of Fastener Suppliers

Fastener suppliers play a crucial role in the supply chain. They source raw materials and manufacture fasteners, ensuring that they meet industry standards and specifications. Suppliers are responsible for providing a wide range of products to cater to different needs. They must keep an inventory that includes various sizes, grades, and materials to accommodate varying customer demands.

Moreover, fastener suppliers also serve as advisors to their customers. They possess extensive knowledge of their products and can offer recommendations based on specific application requirements. For example, they might suggest stainless steel fasteners for environments prone to corrosion or high-temperature alloys for applications subject to extreme heat. This expertise helps customers make informed decisions, ultimately leading to the successful execution of their projects.

Quality Assurance

fastener suppliers

Quality control is paramount in the fastener industry. The integrity of fasteners directly impacts the safety and durability of the final product. Therefore, a reliable fastener supplier conducts stringent quality assurance checks at various stages of the manufacturing process. This includes testing materials for strength, resistance to corrosion, and dimensional accuracy. By adhering to international standards, suppliers ensure that their products can withstand the rigors of their intended applications.

Additionally, suppliers often obtain certifications from industry-standard organizations, which can provide customers with confidence in the quality of their products. Such certifications are essential in industries like aerospace and automotive, where safety is non-negotiable.

Supply Chain Efficiency

In today's fast-paced business environment, timely delivery of fasteners is critical for maintaining production schedules. Fastener suppliers use advanced inventory management systems to track stock levels and predict supply needs. This efficiency can help prevent production delays caused by shortages, allowing manufacturers to meet their deadlines and maintain customer satisfaction. Furthermore, a reliable supplier will often offer just-in-time delivery services, ensuring that the necessary fasteners arrive exactly when needed.

The Importance of Choosing the Right Supplier

Choosing the right fastener supplier can have a significant impact on the overall success of a project. Factors to consider include the supplier's reputation, range of products, quality control processes, customer service, and delivery capabilities. A trusted supplier not only ensures the quality of fasteners but also provides responsive service and support, helping to resolve issues quickly and effectively.

Conclusion

In conclusion, fastener suppliers are indispensable contributors to the operational success of numerous industries. By providing high-quality products, expert advice, and efficient service, they enable manufacturers to build reliable, robust products that stand the test of time. As industries continue to evolve and demand higher standards, the role of fastener suppliers will only grow in significance, making them vital partners in the pursuit of innovation and excellence.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025