Exploring the Benefits and Applications of 10% 2024 Flange Nut in Modern Engineering Solutions

Août . 14, 2024 08:51 Back to list

Exploring the Benefits and Applications of 10% 2024 Flange Nut in Modern Engineering Solutions

Understanding 10% 2024 Flange Nut Characteristics and Applications

The 10% 2024 flange nut is an essential component commonly used in the aerospace and automotive industries due to its high strength-to-weight ratio and exceptional mechanical properties. This article delves into the characteristics, applications, and advantages of the 10% 2024 flange nut.

Composition and Properties

The 2024 aluminum alloy, from which the 10% 2024 flange nut derives its name, is primarily composed of aluminum, copper, and small amounts of manganese, silicon, magnesium, and other elements. The 10% in its designation typically refers to the specific variation or treatment of the alloy that ensures enhanced performance characteristics, often related to its stress corrosion resistance and overall hardness.

Aluminum alloys, particularly 2024, exhibit an excellent combination of strength and lightweight properties. With a tensile strength of around 480 MPa (69,000 psi) and excellent fatigue resistance, the 10% 2024 flange nut can effectively withstand extreme conditions, making it ideal for high-performance applications. The addition of copper improves its overall tensile strength and helps maintain ductility.

Design Features

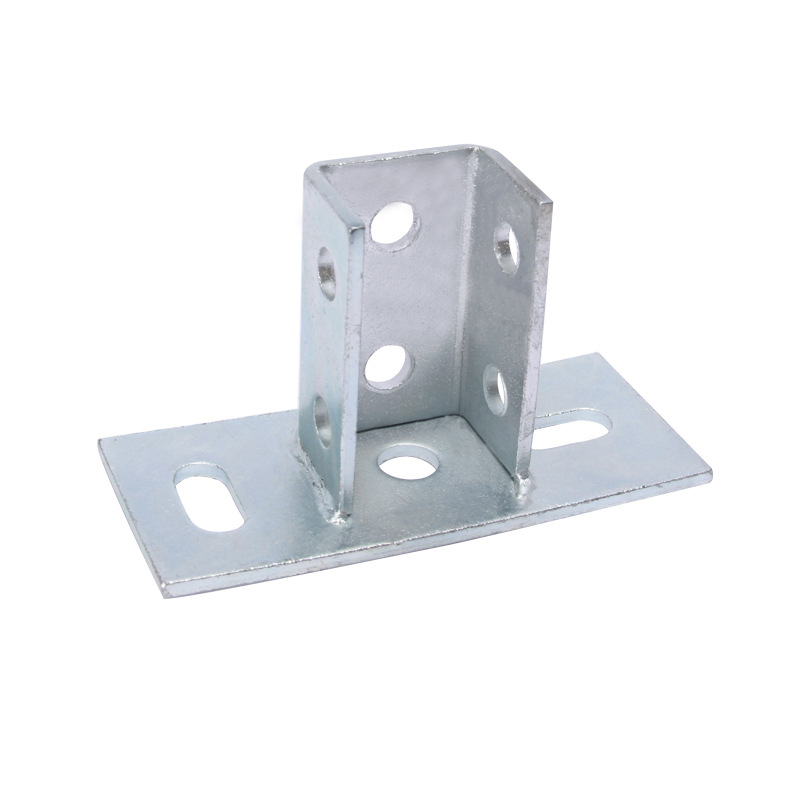

Flange nuts are designed with a larger surface area compared to standard nuts, providing several advantages in assembly applications. The flange, which acts like a washer, distributes the load more evenly across the joint, reducing the risk of damage to the material being fastened. This design feature is particularly beneficial in applications where vibration or movement may lead to loosening of standard nuts.

The 10% 2024 flange nut is also often treated to enhance its corrosion resistance, ensuring longevity even in demanding environments. When paired with appropriate fasteners, these nuts form secure joints that can withstand high temperatures, making them ideal for aerospace applications.

Applications

10 24 flange nut

The aerospace industry extensively uses the 10% 2024 flange nut due to its lightweight and high-strength characteristics. Aircraft structures, including fuselages, wings, and other critical components, require fasteners that can maintain structural integrity over time, particularly in high-stress environments.

In addition to aerospace, the automotive industry also employs 10% 2024 flange nuts in high-performance vehicles where weight reduction without sacrificing strength is essential. These nuts facilitate efficient assembly and disassembly processes in manufacturing, repair, and maintenance operations.

Another key application area includes military and defense equipment, where reliability and durability in extreme situations are non-negotiable. The use of 10% 2024 flange nuts ensures that critical military hardware can perform consistently under severe conditions.

Advantages

One of the significant advantages of using a 10% 2024 flange nut is its ability to minimize the risk of loosening, thanks to its wider surface area which enhances frictional grip. This characteristic is vital in applications where movement and vibrations can compromise the joint integrity.

Moreover, the lightweight nature of aluminum alloys, combined with their remarkable strength, allows for weight savings in construction projects, contributing to improved efficiency and fuel economy in vehicles and aircraft.

The resistance to corrosion further enhances the lifespan of these fasteners, thereby reducing maintenance costs and the frequency of replacements, which is particularly beneficial in industries relying on performance and safety.

Conclusion

In conclusion, the 10% 2024 flange nut stands out as a critical component in sectors demanding high-performance standards. Its blend of strength, lightweight properties, innovative design, and resistance to harsh environmental conditions makes it indispensable in modern engineering applications. Understanding the significance of this fastener is crucial for engineers, manufacturers, and those involved in design processes across aerospace, automotive, and defense industries. As technology advances, the application of such robust materials is likely to evolve, leading to even more innovative approaches in engineering design.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025