Exploring the Benefits and Applications of Custom Spring Washers for Enhanced Mechanical Performance

Ago . 13, 2024 10:48 Back to list

Exploring the Benefits and Applications of Custom Spring Washers for Enhanced Mechanical Performance

Understanding Custom Spring Washers Applications and Benefits

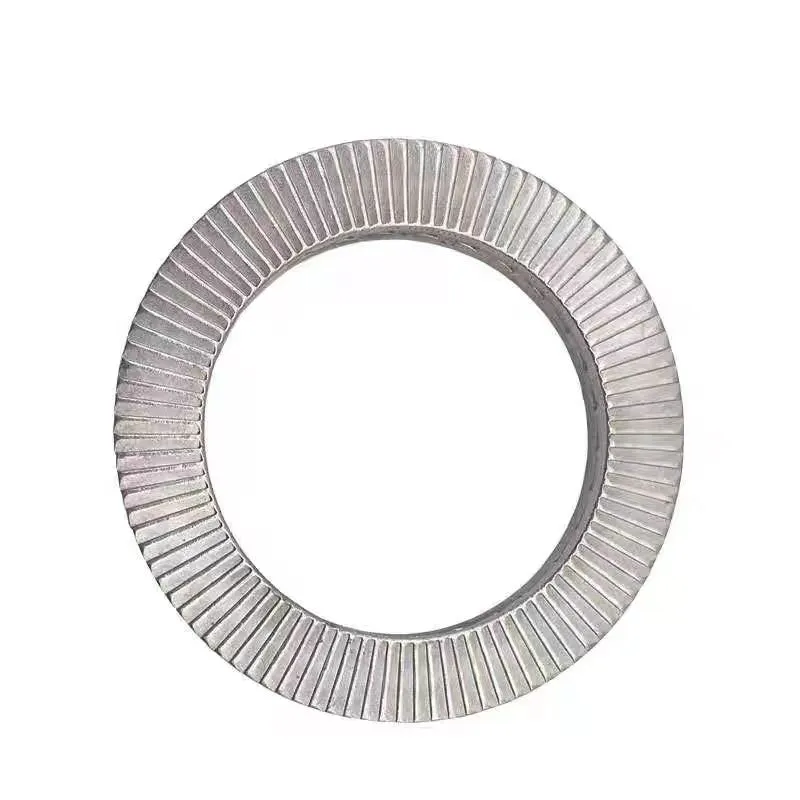

Spring washers are essential components in various mechanical applications, providing a unique solution to particular challenges faced by engineers and manufacturers. Custom spring washers, in particular, cater to the specific needs of different industries, ensuring that they can meet diverse operational demands. This article explores what custom spring washers are, their applications, and the benefits they offer.

What Are Spring Washers?

Spring washers are ring-shaped components designed to provide tension, absorb shock, and maintain a tight connection between assembled parts. They are typically made from materials such as stainless steel, carbon steel, or specialty alloys, and their design allows them to compress and expand under mechanical loads. This functionality makes them different from standard flat washers, which merely distribute the load without providing any additional tension.

The Need for Custom Spring Washers

In many cases, standard spring washers may not be sufficient to meet the specific requirements of a given application. Factors such as load capacity, size, shape, and material can vary greatly across different industries and applications. Custom spring washers are designed to meet these unique specifications, providing a tailored solution that enhances performance and reliability.

Manufacturers who require specific dimensions or material properties often turn to custom spring washers. For instance, in the aerospace industry, components need to withstand extreme temperatures and environments. Custom spring washers designed for this sector often leverage advanced materials and coatings to ensure longevity and performance under harsh conditions.

Applications of Custom Spring Washers

Custom spring washers find their applications in various industries, including

custom spring washers

2. Electronics In electronic devices, custom spring washers are frequently used to secure electrical components, providing the necessary tension to maintain contact while absorbing vibrations that could lead to disconnections.

3. Manufacturing Machinery Custom washers are used in manufacturing equipment and machinery to ensure parts remain fixed and operational, especially in high-vibration environments. They help to reduce machine downtime and extend the life of critical components.

4. Construction In construction applications, custom spring washers can be employed in fasteners to ensure structural integrity and prevent loosening due to dynamic loads caused by wind or seismic activity.

Benefits of Custom Spring Washers

Choosing custom spring washers offers a variety of benefits. Firstly, they allow manufacturers to optimize their designs for specific applications, leading to improved performance. By using washers that are precisely tailored to their operational needs, companies can achieve better load distribution and minimize the risk of component failure.

Additionally, custom washers can be manufactured from specialized materials that resist corrosion, temperature extremes, or wear, which can enhance the durability of the application. This customization also enables the integration of unique shapes and sizes that may not be available in standard options.

Lastly, custom spring washers can ultimately lead to cost savings. By preventing mechanical failures and optimizing the performance of critical components, they help organizations avoid costly repairs and downtime.

Conclusion

Custom spring washers play a crucial role in many industrial applications by delivering tailored solutions that standard products may not provide. Their ability to offer specific sizes, shapes, and material properties makes them indispensable in various fields, ensuring that mechanical systems operate smoothly and efficiently. By investing in custom spring washers, manufacturers can enhance the reliability and longevity of their products, ultimately leading to greater operational success.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025