m25 stainless steel washers

Nov . 15, 2024 10:52 Back to list

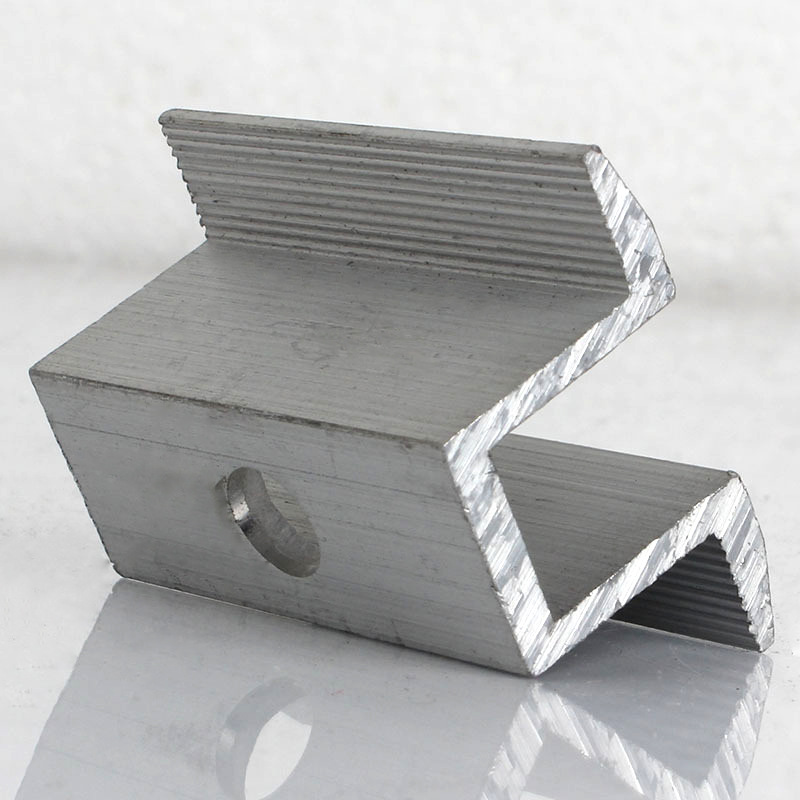

m25 stainless steel washers

The Importance of M25% Stainless Steel Washers in Various Applications

When it comes to fastening and securing components in engineering and construction, the importance of washers cannot be overstated. Among the many varieties available, M25% stainless steel washers stand out for their durability, resistance to corrosion, and overall reliability. This article delves into the features, benefits, and applications of M25% stainless steel washers, making them an essential component in numerous industries.

Understanding M25% Stainless Steel Washers

M25% stainless steel washers are classified based on their size, specifically the diameter of the hole, which is designed to fit M25 bolts or screws. The “M” designation signifies that these are metric washers, with the number indicating the nominal diameter in millimeters. Washers serve multiple purposes, including distributing load, preventing damage to surfaces, and reducing the risk of loosening due to vibration or movement.

Stainless steel is a popular choice for washers due to its exceptional properties. The “25%” in the designation often refers to the percentage of chromium in the steel, which contributes to its corrosion resistance and overall strength. Stainless steel washers are particularly beneficial in environments exposed to moisture, chemicals, and various weather conditions.

Key Benefits of M25% Stainless Steel Washers

1. Corrosion Resistance One of the standout features of stainless steel washers is their ability to withstand rust and corrosion. This makes them an ideal choice for outdoor applications or in industries where exposure to water or chemicals is common.

2. Strength and Durability Manufactured to withstand high loads, M25% stainless steel washers provide the strength needed to secure components without deforming or breaking, ensuring long-lasting performance in critical applications.

3. Vibration Resistance In mechanical systems, vibrations can lead to loosening of fasteners. The large surface area of washers helps to increase friction, stabilizing the connections and minimizing the risk of loosening over time.

4. Aesthetic Appeal Stainless steel features a clean and polished finish that improves the visual appeal of products. This is particularly important in applications where aesthetic appearance matters, such as architectural and decorative installations.

m25 stainless steel washers

5. Versatility M25% stainless steel washers are versatile and can be used in a wide range of industries, including automotive, construction, manufacturing, and electronics. Their standard sizing makes them easily compatible with various standard fasteners.

Applications of M25% Stainless Steel Washers

M25% stainless steel washers find use in a variety of applications

1. Construction and Structural Engineering In constructions such as bridges, buildings, and other infrastructures, these washers are utilized to secure bolts that hold structural components together, ensuring stability and safety.

2. Automotive Industry Stainless steel washers are essential in cars, trucks, and other vehicles, providing secure fastening in engine components, chassis, and body assembly, where exposure to heat and moisture is prevalent.

3. Household Appliances In household appliances such as washing machines, refrigerators, and dishwashers, stainless steel washers are used to maintain structural integrity and prevent disassembly over time.

4. Electronic Equipment The electronics industry benefits from the use of M25% washers in securing components on printed circuit boards (PCBs) or other electronic frameworks, protecting sensitive components from vibrations.

5. Marine Applications Given their corrosion resistance, M25% stainless steel washers are perfect for marine environments, where saltwater can rapidly degrade lesser materials.

Conclusion

M25% stainless steel washers are vital components across various industries, offering a combination of durability, strength, and aesthetic value. Their resistance to corrosion and ability to handle demanding environments make them a preferred choice in applications where longevity and reliability are paramount. By understanding their features and applications, engineers and manufacturers can make informed decisions about their fastening solutions, ensuring enhanced performance and safety in their projects.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025